Magnetic iron ore beneficiation method

A beneficiation method and magnetite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high impurity and iron content, high water content and high powder content, and achieve improved metal recovery rate, short process, The effect of improving the efficiency of crushing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

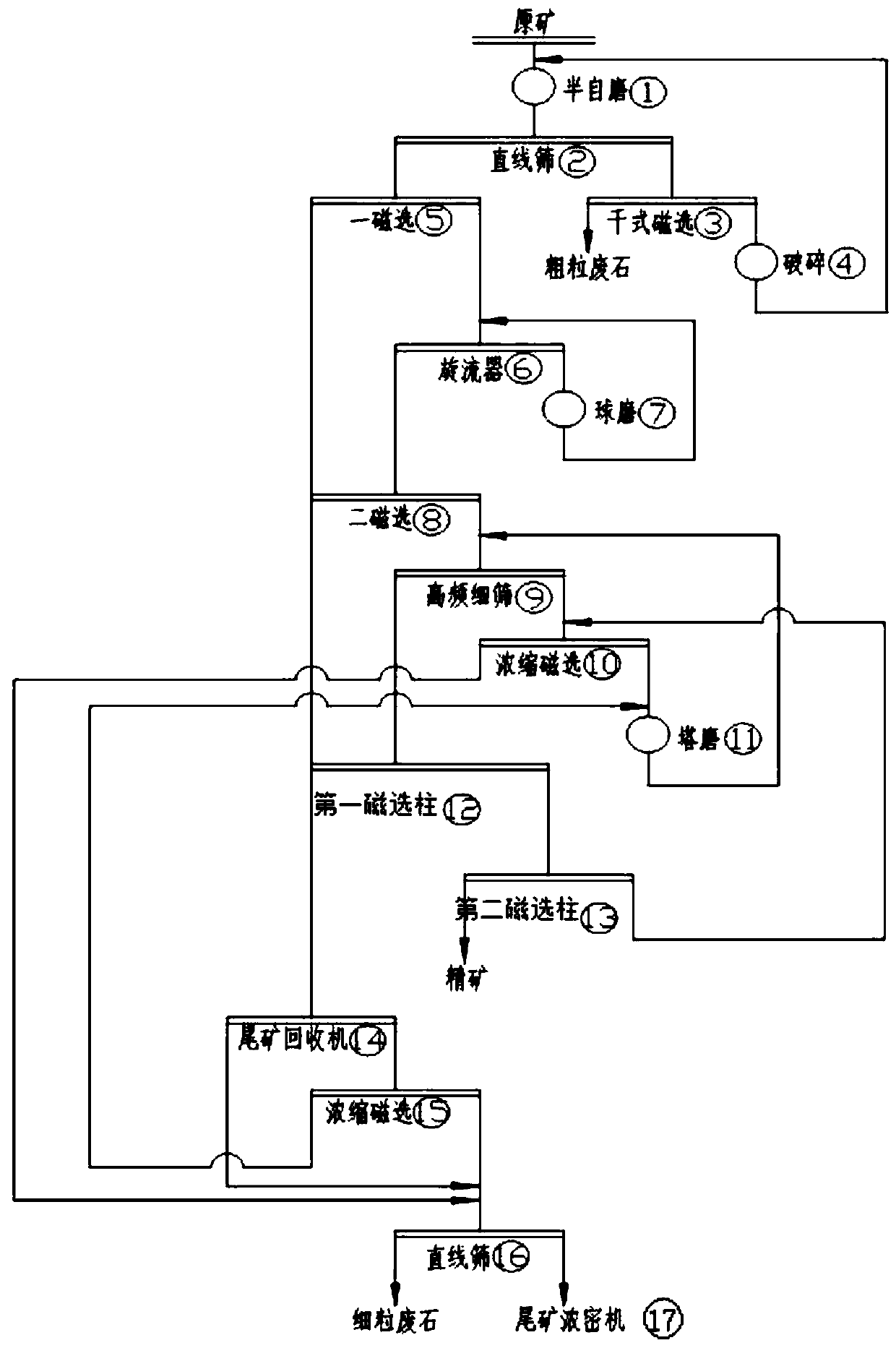

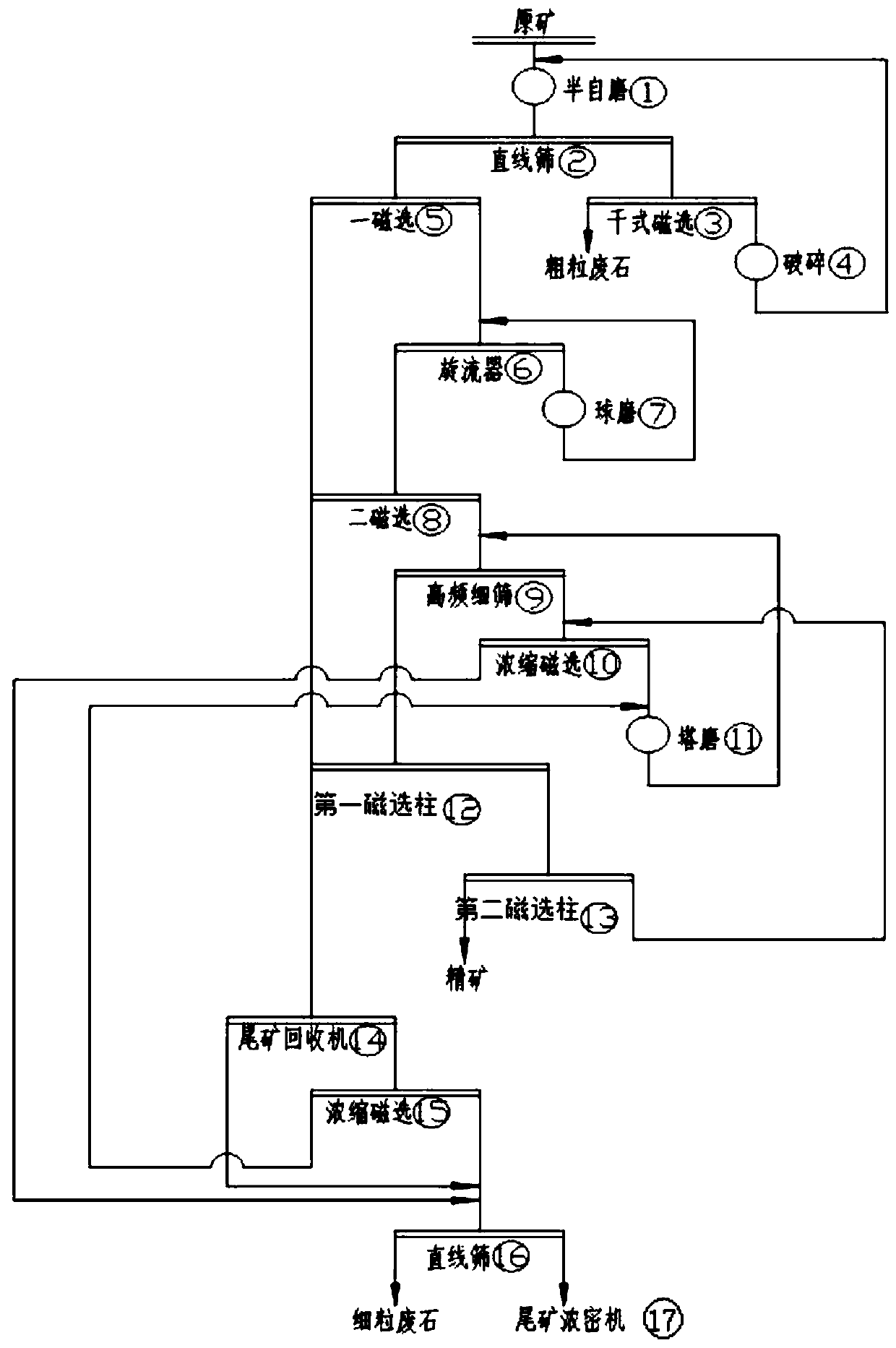

[0034] Such as figure 1 As shown, a beneficiation method of magnetite, the steps are:

[0035] A. The ore with a particle size of 0-350mm and a grade of 25%-35% is conveyed by a semi-automatic mill 1 by the ore-collecting belt, self-grinding to a particle size of -60mm;

[0036] B. The first-stage semi-automatic mill discharge adopts linear sieve 2 for screening, and the products on the linear sieve 2 (-60mm—+3mm) are discarded by weak magnetic dry separator 3. The tailings are used as building materials and dry magnetic The concentrate enters the stone crusher 4 for crushing, and the crushed product returns to the semi-automatic mill 1 for re-grinding;

[0037] C. The product under the linear sieve 2 (-3mm) enters the first stage wet magnetic separator 5 for separation, the magnetic field strength is 350-400mT, and the first stage magnetic concentrate grade is 45%-52%;

[0038] D. The magnetic concentrate of the first stage is transported by a slurry pump to the hydrocyclone 6 for cl...

Embodiment 2

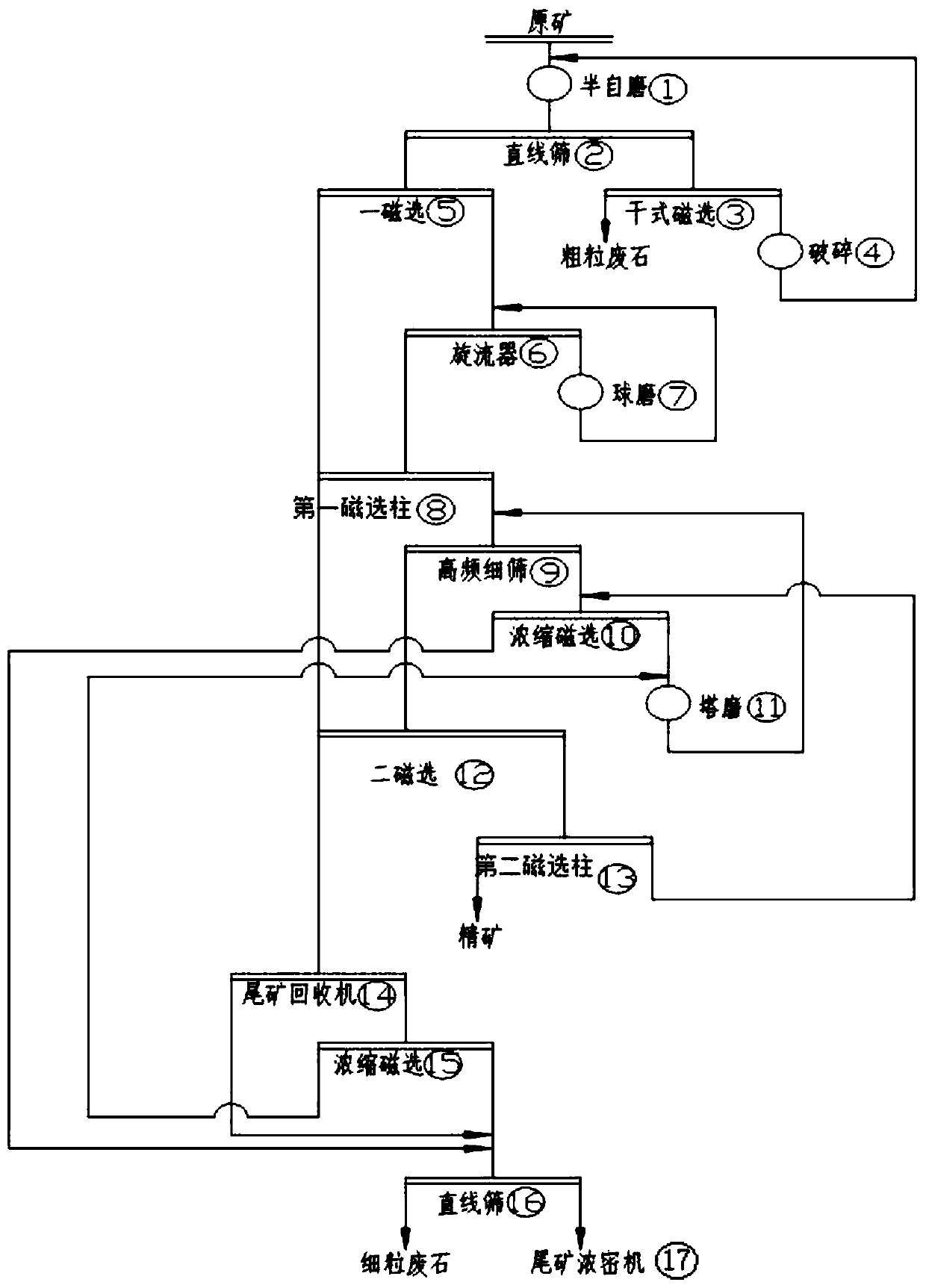

[0047] Such as figure 2 As shown, the two-stage weak magnetic separator and the first magnetic separation column in the first scheme are interchanged. The first magnetic separation column not only provides the purpose of beneficiation, but also plays a role in desilting the concentrate. After the ore is pre-desludged, it can improve the operation efficiency of the subsequent 9 high-frequency fine screens and reduce the sludge content of the concentrate. After the second stage of weak magnetic separator magnetic separation, it can reduce the inclusion of the concentrate and improve the grade of the concentrate.

[0048] A method for beneficiating magnetite, the steps are:

[0049] A. The ore with a particle size of 0-350mm and a grade of 25%-35% is conveyed by a semi-automatic mill 1 by the ore-collecting belt, self-grinding to a particle size of -60mm;

[0050] B. One-stage semi-automatic mill discharge (-60mm) adopts linear sieve 2 for sieving, linear sieve 2 (-60mm—+3mm) products...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com