Magnetic shaker

A technology of magnetic force and magnetic system, applied in the field of shakers, can solve the problems of magnetic separation inclusions, etc., and achieve the effect of increasing the differential action, increasing the sorting efficiency, and improving the sorting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

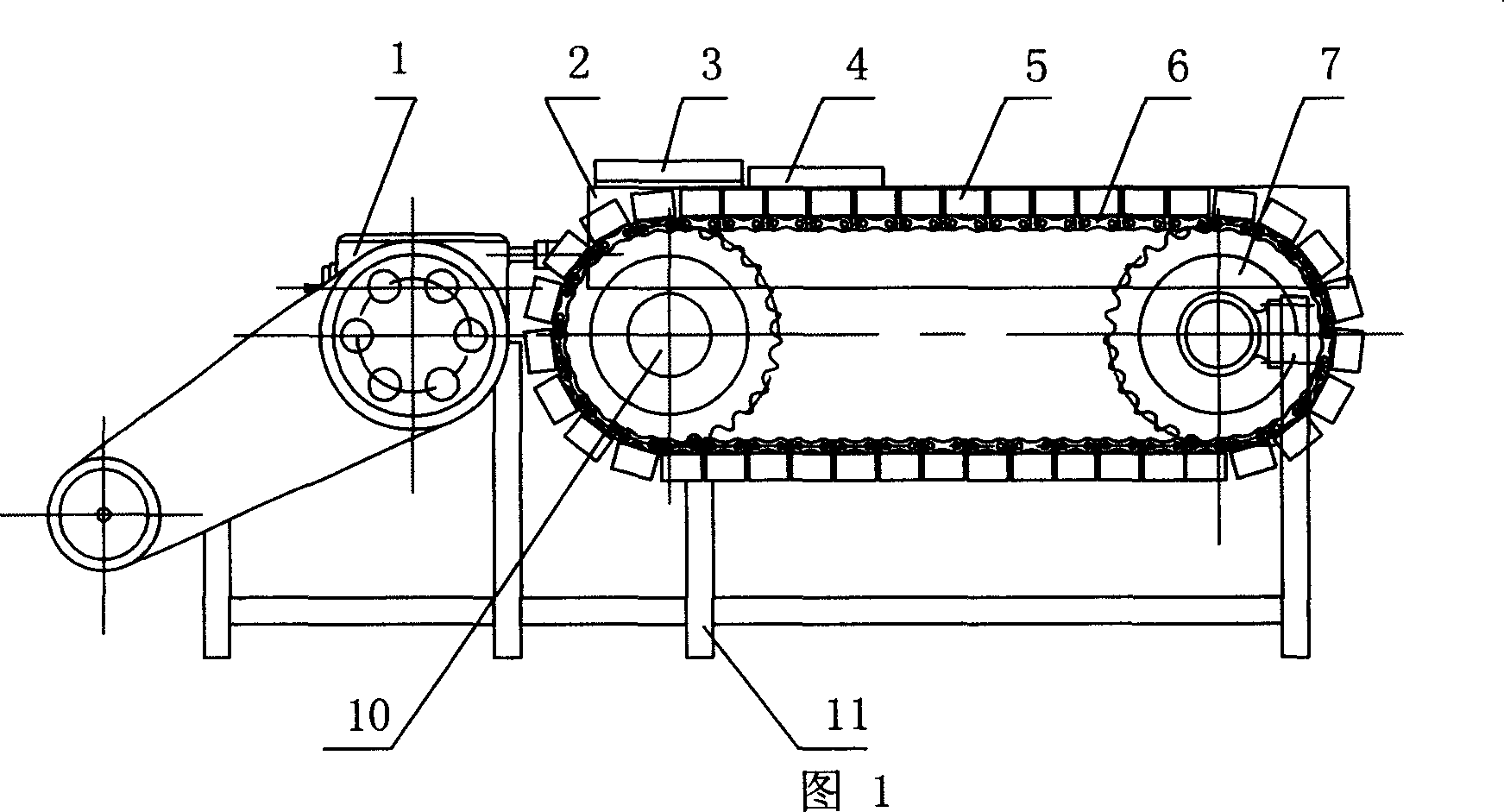

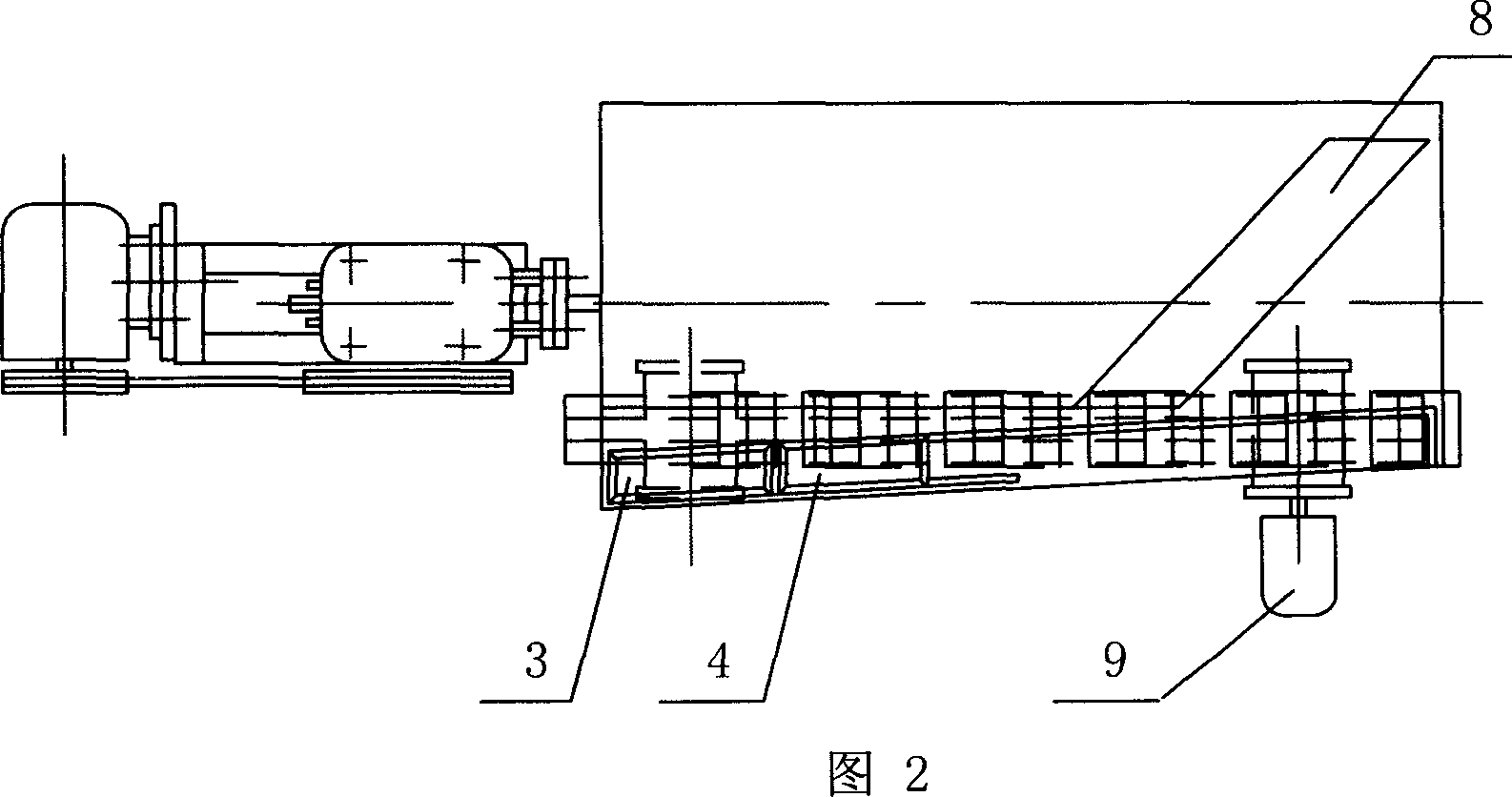

[0014] Embodiment 1, as shown in the figure, the present invention comprises support 11, is provided with head of a bed 1 and bed surface 2 on support 11, is respectively provided with ore feeding tank 3 and water supply tank 4 on bed surface 2, on bed surface Bed strips 8 are also provided. In addition, a drive mechanism 9 is also provided on the bracket, which may be a motor or the like. A magnetic system carrier mechanism 6 running along the direction of the bed surface is arranged under the bed surface 2 , and a magnetic system 5 is arranged on the magnetic system carrier mechanism 6 . The magnetic carrier mechanism 6 can be arranged vertically or horizontally.

[0015] The magnetic system carrier mechanism 6 in the present invention is composed of a driving sprocket 7 , a driven sprocket 10 and a transmission chain arranged between the driving sprocket 7 and the driven sprocket 10 . The magnetic carrier mechanism 6 is arranged along the length direction of the bed surfa...

Embodiment 2

[0017] Embodiment 2, as shown in the figure, the present invention comprises support 11, is provided with head of a bed 1 and bed surface 2 on support 11, is respectively provided with ore feeding tank 3 and water supply tank 4 on bed surface 2, on bed surface Bed strips 8 are also provided. In addition, a drive mechanism 9 is also provided on the bracket, which may be a motor or the like. A magnetic system carrier mechanism 6 running along the direction of the bed surface is arranged under the bed surface 2 , and a magnetic system 5 is arranged on the magnetic system carrier mechanism 6 . The magnetic carrier mechanism 6 can be arranged vertically or horizontally.

[0018] The magnetic system carrier mechanism 6 is composed of a driving wheel, a driven wheel and a conveyor belt arranged between the driving wheel and the driven wheel. The magnetic carrier mechanism 6 is arranged along the length direction of the bed surface. Alternatively, the magnetic carrier mechanism 6 i...

Embodiment 3

[0020] Embodiment 3, as shown in the figure, the present invention comprises support 11, is provided with head of a bed 1 and bed surface 2 on support 11, is respectively provided with ore feeding tank 3 and water supply tank 4 on bed surface 2, on bed surface Bed strips 8 are also provided. In addition, a drive mechanism 9 is also provided on the bracket, which may be a motor or the like. A magnetic system carrier mechanism 6 running along the direction of the bed surface is arranged under the bed surface 2 , and a magnetic system 5 is arranged on the magnetic system carrier mechanism 6 . The magnetic carrier mechanism 6 can be arranged vertically or horizontally.

[0021] The magnetic system carrier mechanism 6 includes a horizontal transmission track on which a moving magnetic system carrier is arranged. The magnetic carrier mechanism 6 is arranged along the length direction of the bed surface. Alternatively, the magnetic carrier mechanism 6 is arranged along the width d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com