Magnetic sealing tape

A sealing tape, magnetic technology, applied in the directions of ship safety, ships, transportation and packaging, can solve the problems of inability to achieve rapid repair, long repair time, high requirements, etc., and achieve material saving, weak adsorption, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

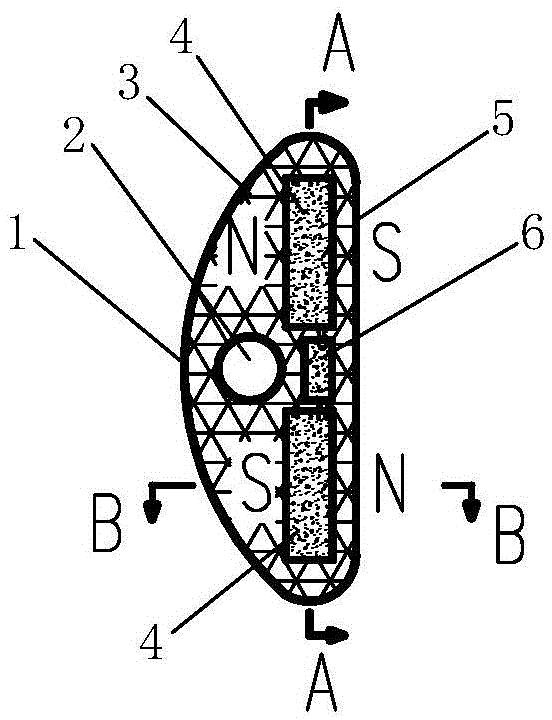

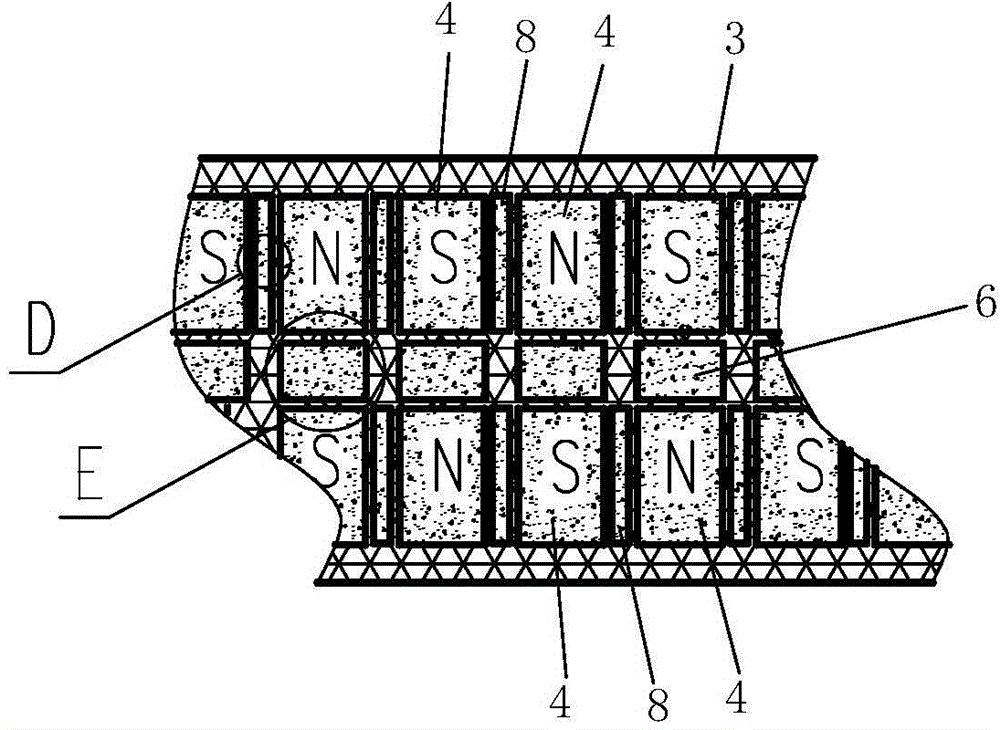

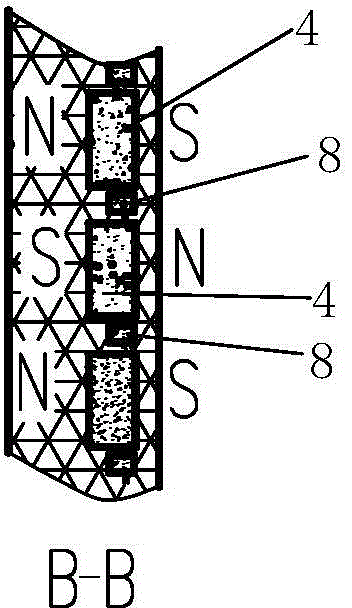

[0018] Such as Figure 1 to Figure 5 As shown, the magnetic sealing tape of the present invention includes a rubber strip body 3, a square magnet I4, a square magnet II6, and a square magnet III8. In this embodiment, the curved surface is an arc surface, and of course the outer surface can also be other curved surfaces. The reduction of the arc surface makes the magnetic induction line form a closed loop in the rubber strip, so that the outside of the arc surface has no adsorption effect on the magnetic permeable material. The inner surface 5 of the strip body is flat. The central part of the strip body 3 is provided with a through hole 2 that runs through the strip body 3 in the longitudinal direction so that the strip body 3 forms a hollow structure. The setting of the through hole 2 makes the strip body 3 softer as a whole and reduces the use of materials. . The volume of the square magnet I4 is larger than that of the square magnet II6 and the square magnet III8. The squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com