Low-grade scheelite branch floating method

A scheelite, low-grade technology, used in flotation, solid separation and other directions, can solve the problems of poor ore adaptability, high beneficiation cost, poor separation effect, etc., to avoid the loss of scheelite and ensure the recovery rate. , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A certain tungsten mine in Yunnan Province is gneiss scheelite, WO 3 The grade is low, and the particle size of scheelite is unevenly distributed from medium to fine; the valuable metals and gangue minerals in the ore are complex, and there are many kinds of gangue minerals, such as apatite, calcite, fluorite and graphite. Easy access to tungsten roughing concentrate, increasing the difficulty of scheelite separation. Get different ore samples in this mining area and test, the ore used in embodiment 1 contains WO 3 0.22%, TS1.38%, organic carbon 0.56%;.

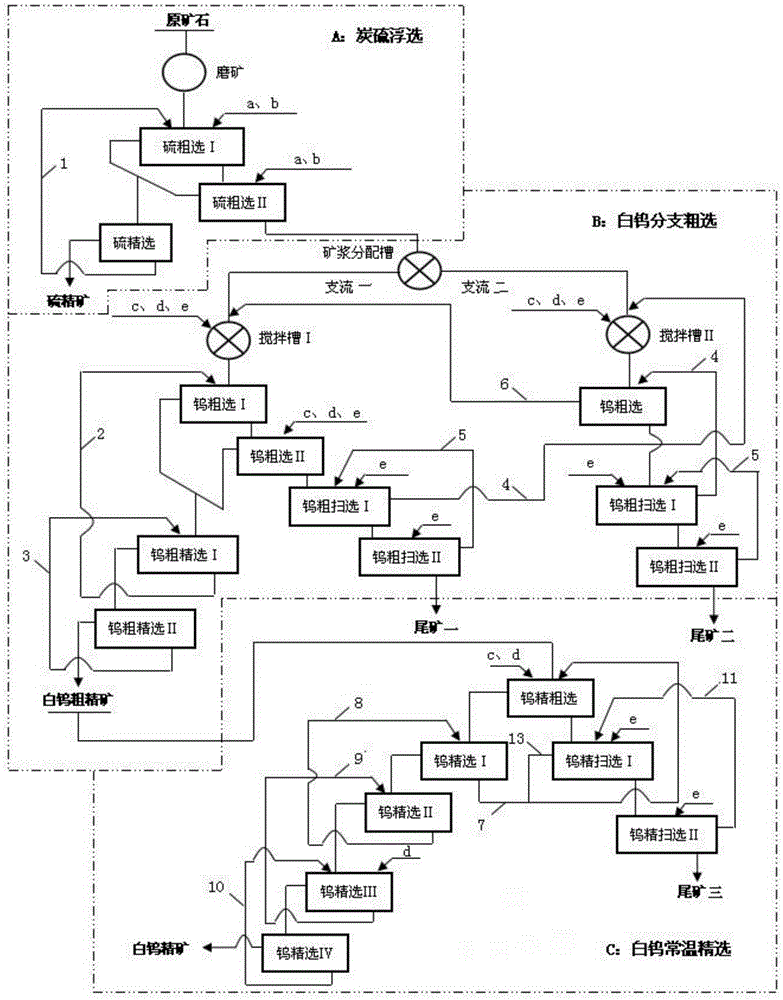

[0038] according to figure 1 Embodiment of the technological process of the present invention, after the raw ore is ground, add 25 g / t of kerosene dosage and 45 g / t of sulfide ore collector to the slurry that is ground to a qualified particle size to carry out the first sulfur roughing, and add 12 g of kerosene dosage / t and the amount of sulfide ore collector 22g / t for the second sulfur roughing, do not ...

Embodiment 2

[0039] Embodiment 2: the ore used contains WO 3 0.28%, TS1.42%, organic carbon 0.48%, implement according to the processing step and condition identical with embodiment 1.

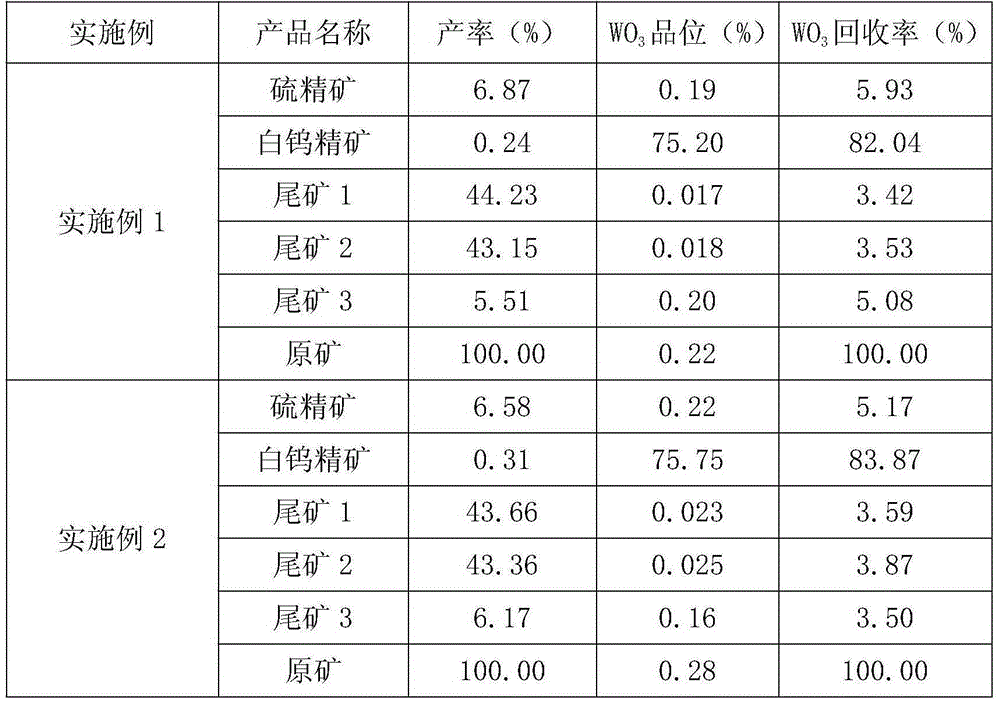

[0040] The recovery indicators of the products of Embodiment 1 and Embodiment 2 of the present invention are shown in Table 1.

[0041] Table 1 embodiment of the present invention product recovery detection index

[0042]

[0043] Shown by embodiment 1, embodiment 2 results shown in table 1, obtainable productive rate is 0.24~0.31%, WO 3 The grade is 75.20~5.75%, WO 3 Scheelite concentrate with a recovery rate of 82.04-83.87% can also be obtained with a yield rate of 6.58-6.87%. WO 3 The grade is 0.19~0.22%, WO 3 The recovery rate is 5.17-5.93% sulfur concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com