A kind of zircon beneficiation combination agent and beneficiation method

A technology of combining chemicals and zircon, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of poor selectivity, waste of resources, multiple recovery rates, etc. Improve grade and recovery rate, collectability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

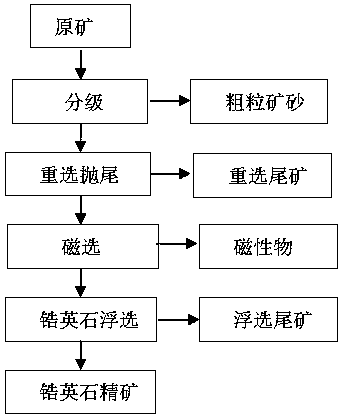

Image

Examples

Embodiment 1

[0025] A zircon mineral beneficiation combination agent, the agent added per ton of raw ore is composed of the following raw materials by weight: sulfuric acid 100-2000g, inhibitor 0-500g, collector 100-1000g, inhibitor is water glass, collector includes The mass ratio of sodium petroleum sulfonate and hydroxamic acid, sodium petroleum sulfonate and hydroxamic acid is 1:1-10:1.

[0026] The hydroxamic acid is salicylic hydroxamic acid or benzhydroxamic acid.

[0027] The method of using the above-mentioned zircon beneficiation combination reagent for beneficiation, the specific steps are as follows:

[0028] (1) Gravity separation, enrichment, and tailing: the crude ore is separated by gravity separation and gangue minerals to obtain heavy minerals;

[0029] (2) Heavy minerals are subjected to magnetic separation, electric separation or combined magneto-electric processes to remove weak magnetic, strong magnetic and conductive materials to obtain coarse zircon concentrate; Separation...

Embodiment 2

[0034] The zircon beneficiation method, the specific steps are as follows:

[0035] (1) Gravity separation, enrichment, and tailing: the crude ore is separated by gravity separation and gangue minerals to obtain heavy minerals;

[0036] (2) Heavy minerals are subjected to magnetic separation, electric separation or combined magneto-electricity processes to remove weak magnetic substances, strong magnetic substances and conductive substances to obtain coarse zircon concentrate;

[0037] (3) Flotation process: adopts a process flow of one roughing, two sweeping, four beneficiation, and medium ore returning in sequence. The reagent system is as follows: roughing section: adjuster sulfuric acid dosage 40g / t, water glass 60g / t, collector (sodium petroleum sulfonate: salicylic hydroxamic acid ratio 1:1) dosage 60g / t, flotation concentration 34%, flotation time 5 minutes; sweeping I sulfuric acid dosage 10g / t, water glass 10g / t, collector dosage 15g / t, flotation concentration 26%, flotat...

Embodiment 3

[0040] The zircon beneficiation method, the specific steps are as follows:

[0041] (1) Gravity separation, enrichment, and tailing: the crude ore is separated by gravity separation and gangue minerals to obtain heavy minerals;

[0042] (2) Heavy minerals are subjected to magnetic separation, electric separation or combined magneto-electricity processes to remove weak magnetic substances, strong magnetic substances and conductive substances to obtain coarse zircon concentrate;

[0043] (3) Flotation process: adopts the process flow of one roughing, two sweeping, two beneficiation, and the middle ore returning in sequence. The reagent system is as follows: roughing section: adjuster sulfuric acid dosage 80g / t, water glass 120g / t, collector (sodium petroleum sulfonate: salicylic hydroxamic acid ratio 2:1) dosage 120g / t, flotation concentration 37%, flotation time 5 minutes; sweep Ⅰ sulfuric acid dosage 20g / t, water glass 20g / t, collector dosage 30g / t, flotation concentration 27%, fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com