Cutter embedding type stalk pulling, ear picking and straw cutting unit body

A unit body and straw technology, which is applied to cutters, agricultural machinery and implements, and applications, can solve the problems of being pressed into the ground, requiring high machine space structure, and being unable to return to the field, so as to reduce power consumption and increase cutting. Good crushing effect and ear picking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

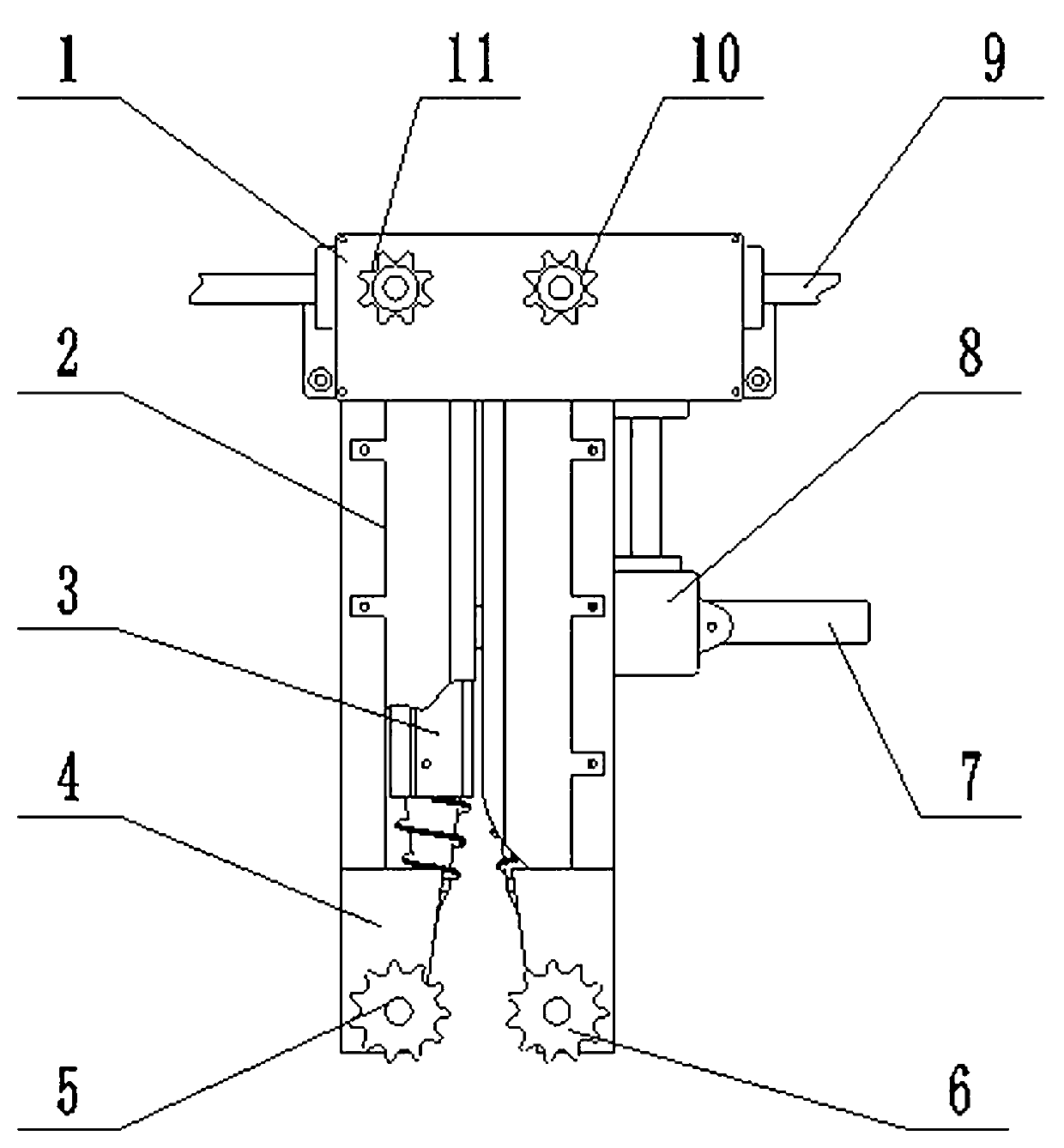

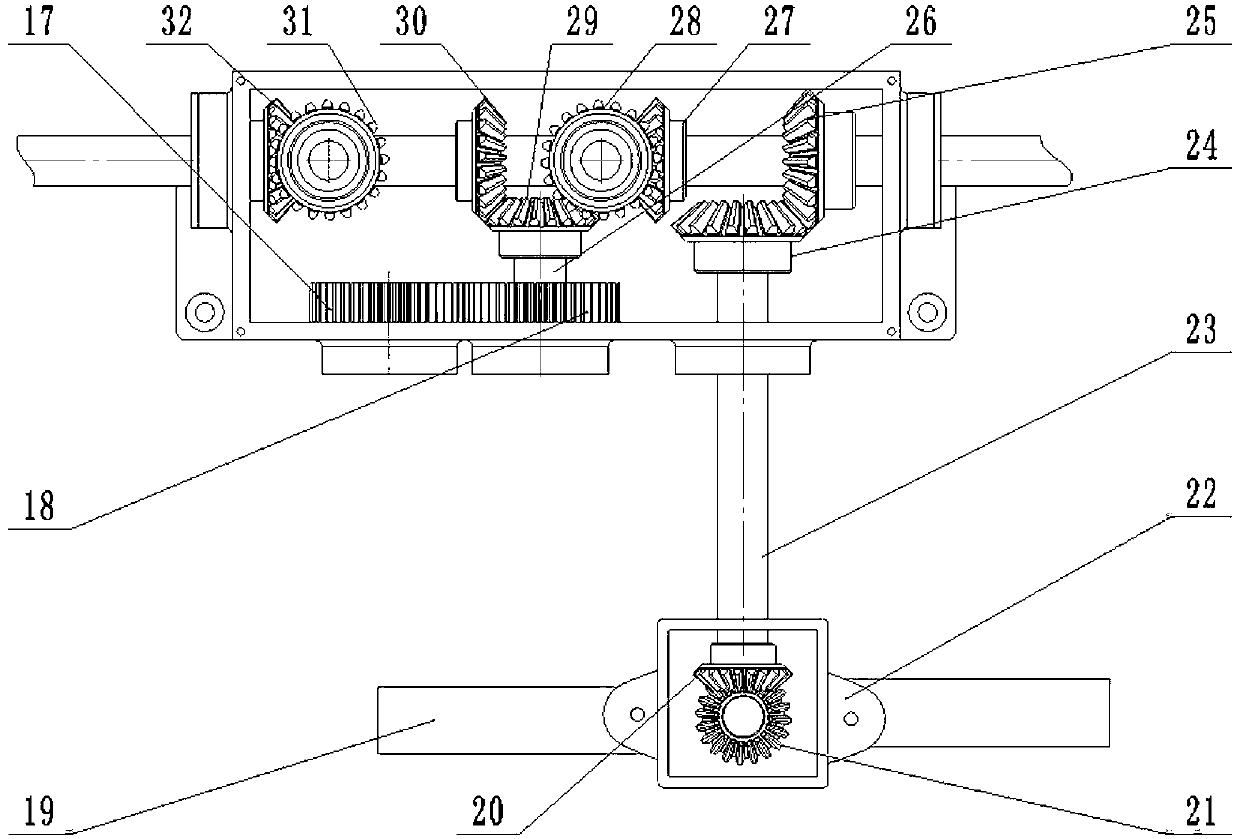

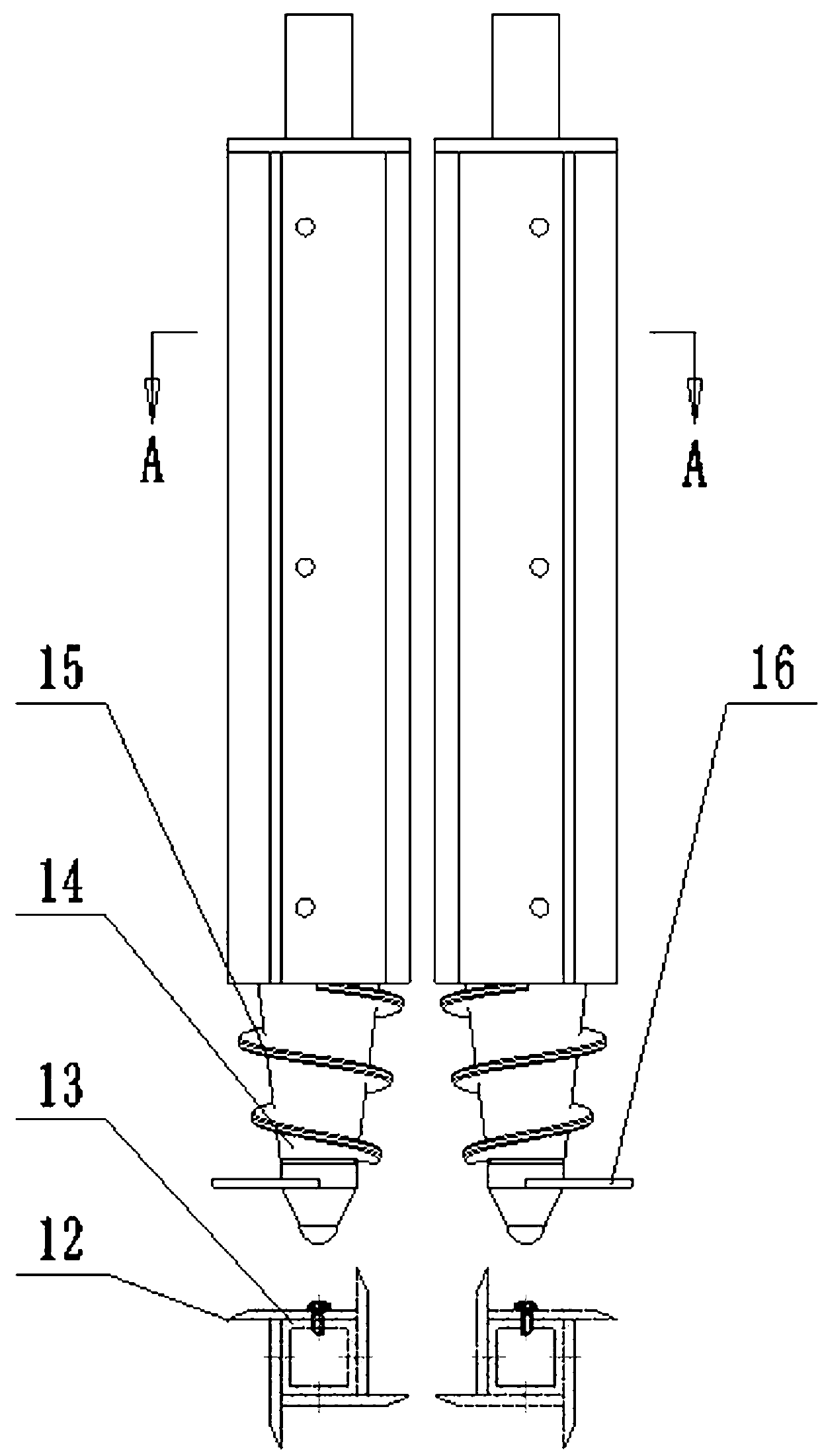

[0015] Such as Figure 1 ~ Figure 3 As shown: the unit body of stem pulling, ear picking and straw crushing mainly includes grain dividing device 4, ear picking device, straw re-cutting device 7, transmission part, etc., wherein grain dividing device 4 is located at the front end of the whole unit body, and the upper part is arranged There are two sprocket wheels 5,6, and the ear picking device is made up of a pair of ear picking plates 2 and a pair of embedded knife type stem rollers 3. It consists of a square steel pipe and a straight knife 12 inlaid on it. It cuts off the straw while picking the ear. The rear end of the ear picking device is connected to the main gearbox 1. The front end is equipped with a grain dividing device 4. The straw re-cutting device 7 is located on the stem pulling roller. The bottom of 3 is composed of small gearbox 8, throwing blade 19, knife holder 22, etc., small gearbox 8 is connected with main gearbox 1 through power distribution shaft 23, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com