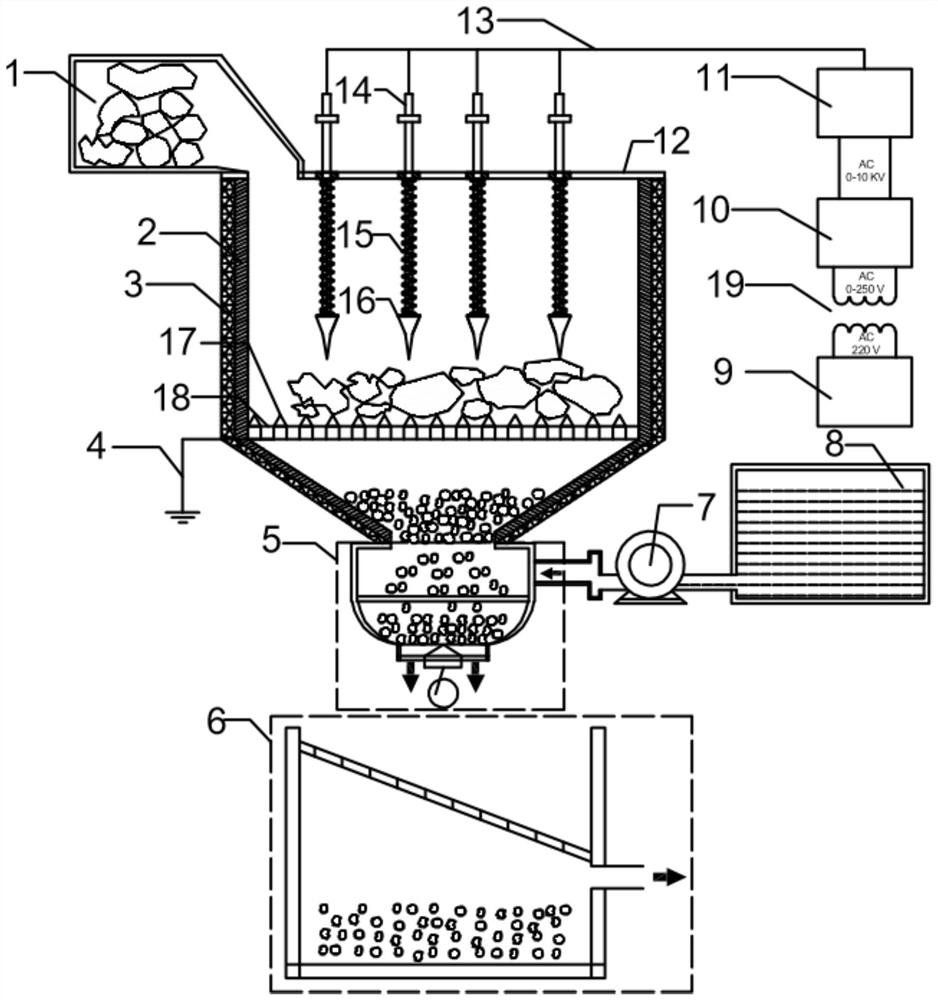

A high-voltage electric pulse pretreatment method for strengthening cassiterite crushing and sorting

A high-voltage electric pulse and pretreatment technology, applied in the field of mineral processing, can solve the problem that useful minerals and gangue minerals cannot be effectively separated, and achieve the effects of reducing ineffective electric crushing process, reducing ore strength and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

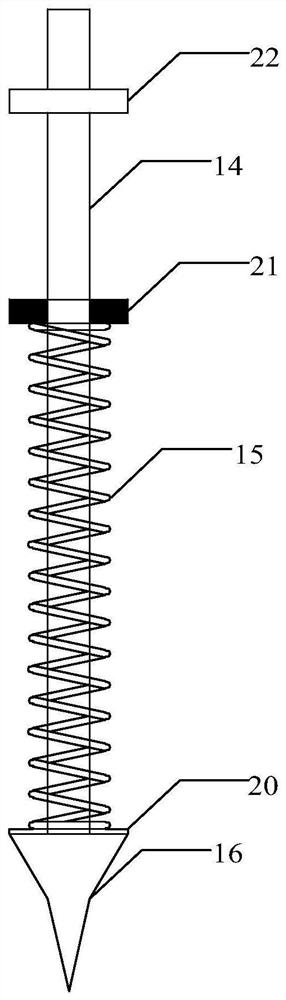

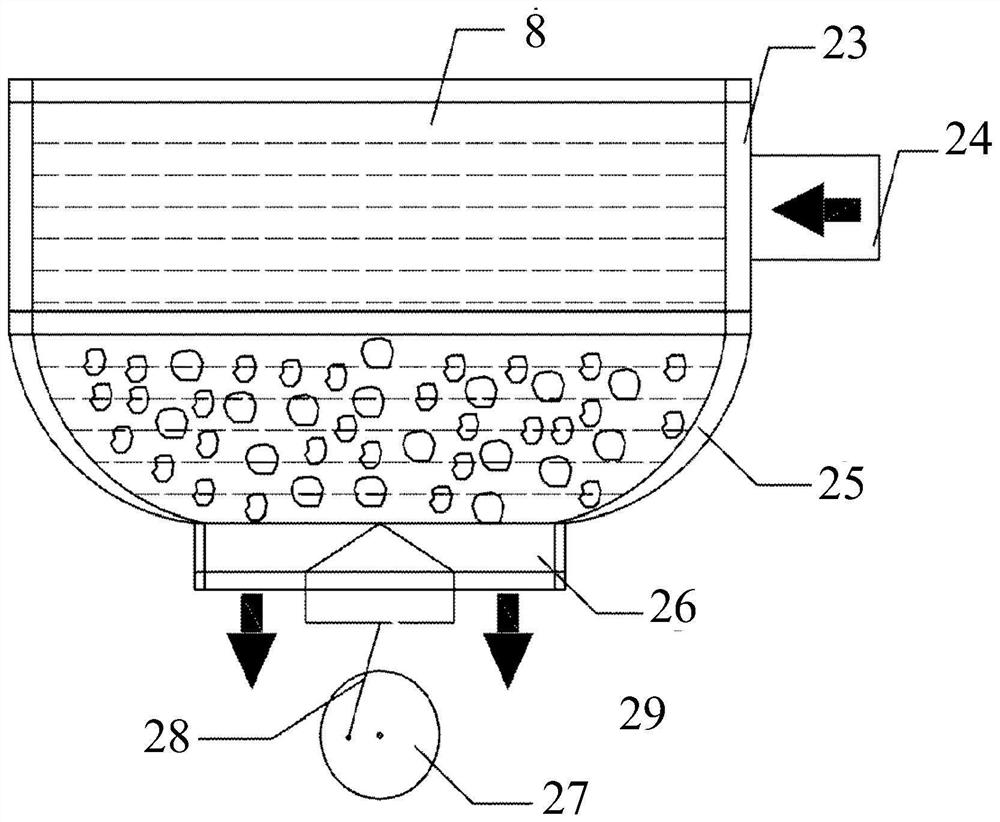

Method used

Image

Examples

Embodiment 1

[0074] The cassiterite ore used is the raw ore of a certain tin mining area in Yunnan Province, and the chemical multi-elements are shown in Table 1 by mass percentage;

[0075] Table 1

[0076] components sn Ni Cu mn TiO 2

Zn CaO content 0.35 0.003 0.75 0.20 0.50 0.049 12.5 components MgO Fe SiO2 Al2O3 P Na 2 o

As content 1.47 34.48 8.57 0.52 0.01 0.042 0.01 components Pb Bi F K 2 o

S content 0.01 0.08 0.2 0.12 18.87

[0077] Chemical phase analysis results are shown in Table 2 by mass percentage;

[0078] Table 2

[0079] Phase tin in cassiterite Tin and others in sulphides Total tin content / % 0.304 0.046 0.35 Proportion / % 86.75 13.25 100

[0080] It can be seen from the table that the grade of copper in the ore is 0.75%, the grade of iron is 34.48%, and the grade of tin is 0.35%. tin and other forms;

[0081] The method is:...

Embodiment 2

[0100] The cassiterite ore sample used is the original ore of a tin mining area in Yunnan Province, and the chemical multi-elements are shown in Table 4 by mass percentage;

[0101] Table 4

[0102] components sn Ni Cu mn TiO2 Zn CaO content 0.35 0.003 0.75 0.20 0.50 0.049 12.5 components MgO Fe SiO2 Al2O3 P Na2O As content 1.47 34.48 8.57 0.52 0.01 0.042 0.01 components Pb Bi F K2O S content 0.01 0.08 0.2 0.12 18.87

[0103] Chemical phase analysis results are shown in Table 5 by mass percentage;

[0104] table 5

[0105] Phase tin in cassiterite Tin and others in sulphides Total tin content / % 0.304 0.046 0.35 Proportion / % 86.75 13.25 100

[0106] It can be seen from the table that the grade of copper in the ore is 0.75%, the grade of iron is 34.48%, and the grade of tin is 0.35%. Tin and other forms;

[0107] Method is with embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com