Method and apparatus for humidification and temp. control of incoming fuel cell process gas

A fuel cell and process gas technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as slow response, insufficient dynamic controllability, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Description of preferred embodiments

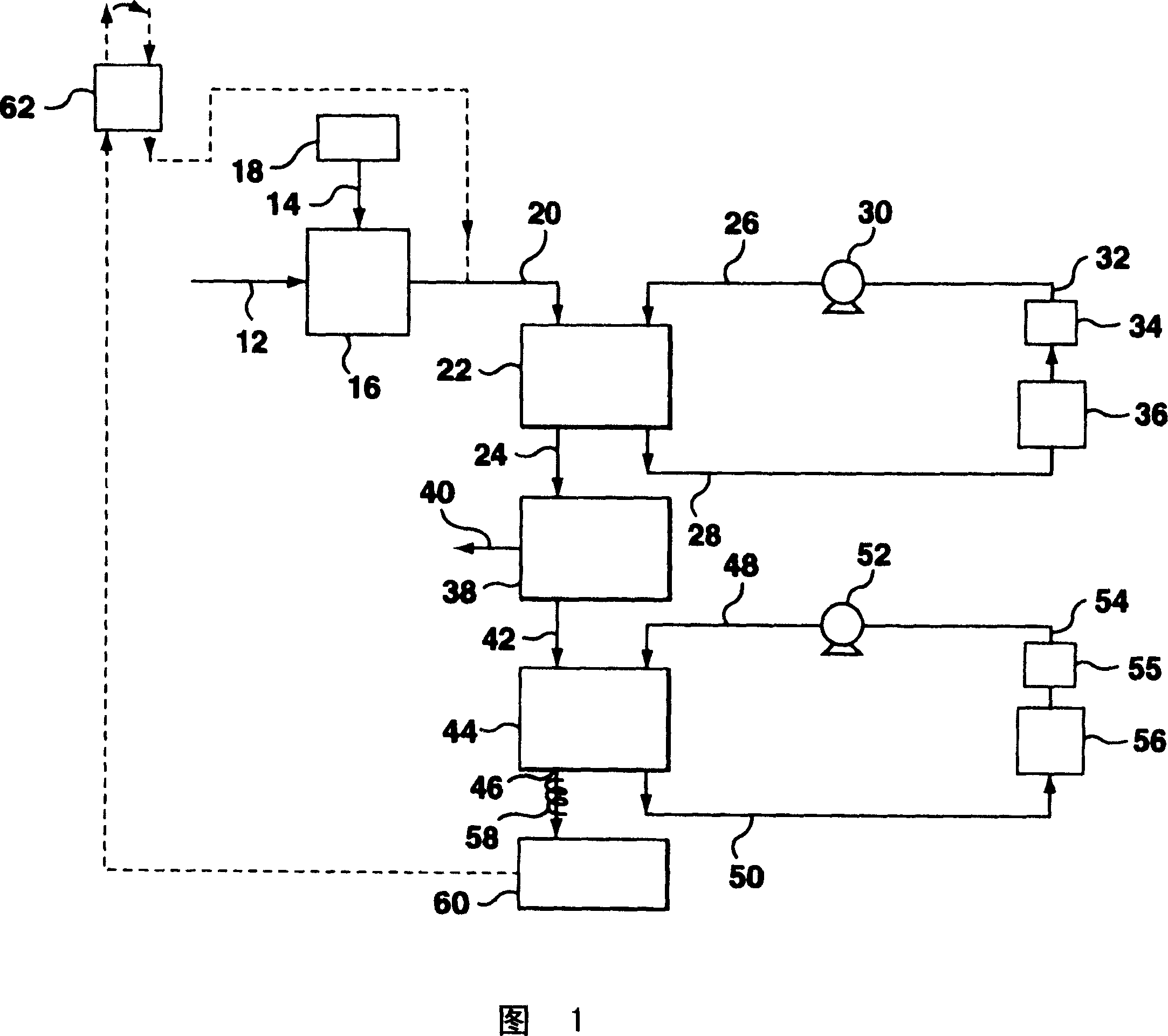

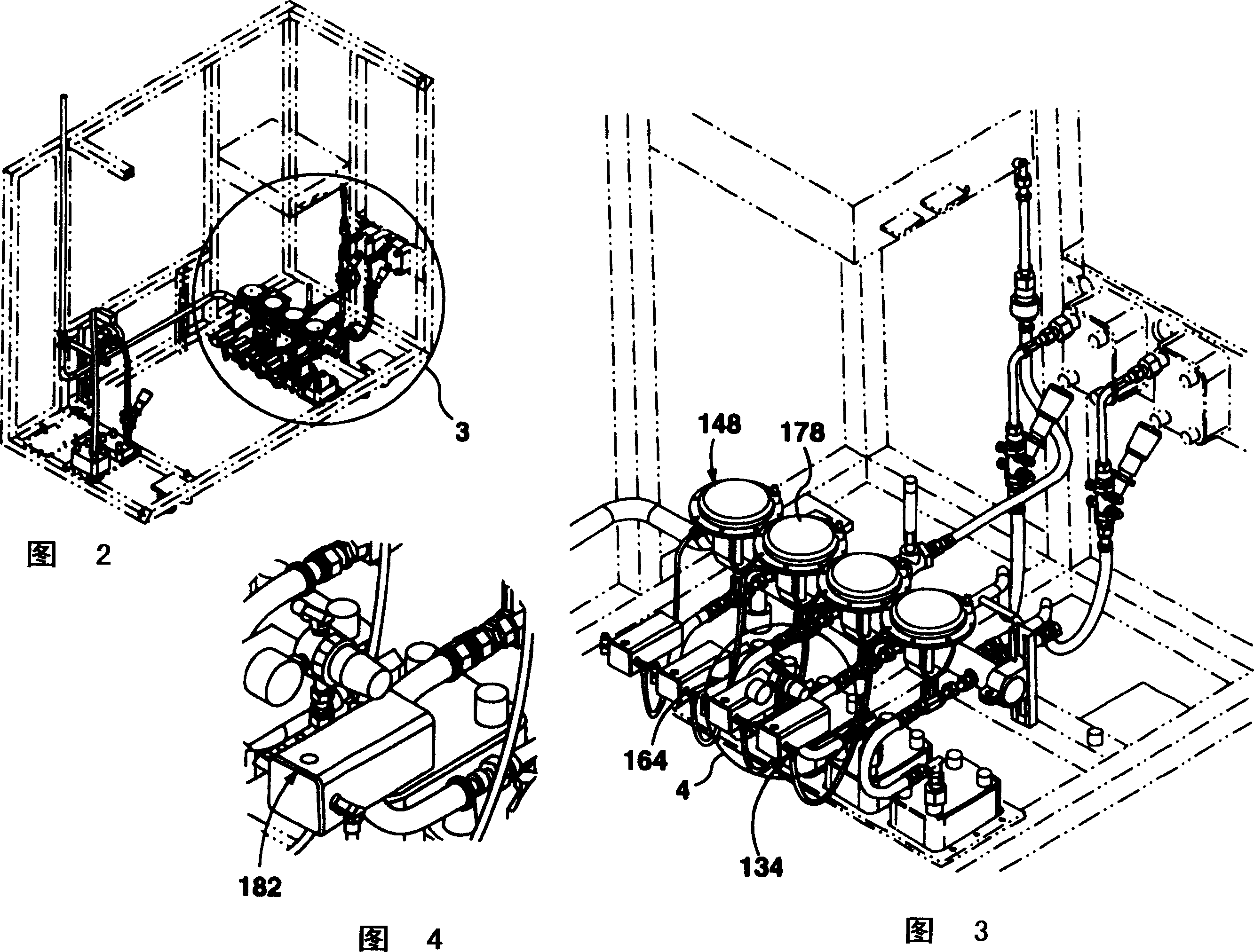

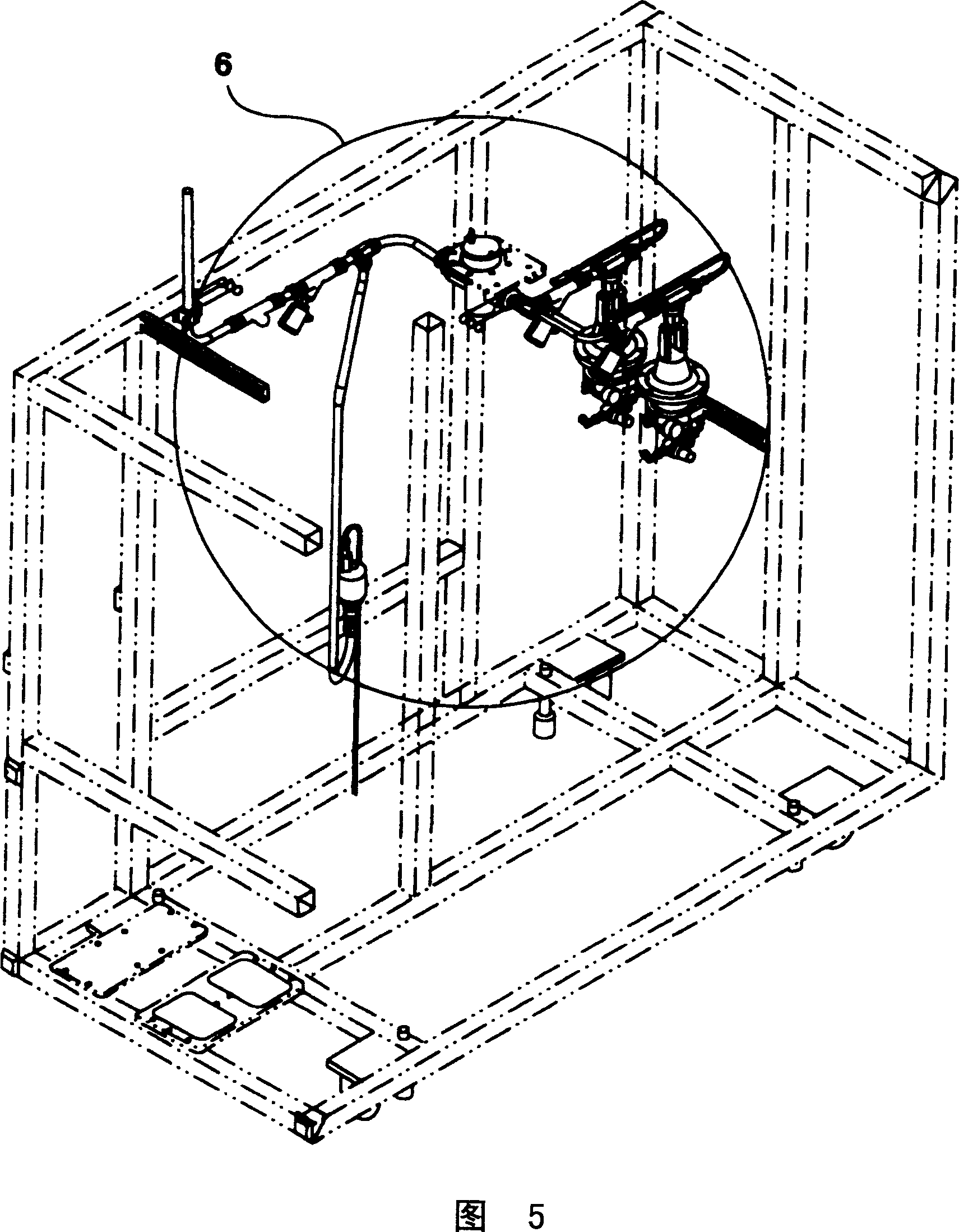

[0041] Referring first to Figure 1, there is shown a schematic flow diagram of a process gas flow for a process gas. It is to be understood that the invention is applicable to two gases, fuel and oxidant gas, and for this purpose the flow diagram of Figure 1 can be replicated as a flow diagram for two sets of process gas flow lines. The embodiments of Figures 2-6 represent the invention for two process gas lines.

[0042] Referring to Figure 1, both the process gas stream 12 and the steam line 14 are connected to a saturator 16 for increasing the humidity of the gas stream. Steam is provided by a steam source, indicated schematically at 18 . Saturator 16 includes injectors that inject steam into the process gas stream to heat and humidify the process gas stream.

[0043]Line 20 leads from saturator 16, which contains supersaturated process gas. Line 20 enters a first heat exchanger 22 . The first heat exchanger 22 is a flat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com