Biodegradable polymer composition for the manufacture of articles having a high heat deflection temperature

A heat distortion temperature and biodegradation technology, applied in the field of heat distortion temperature products, can solve problems such as deformation, adverse effects on industrial processability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

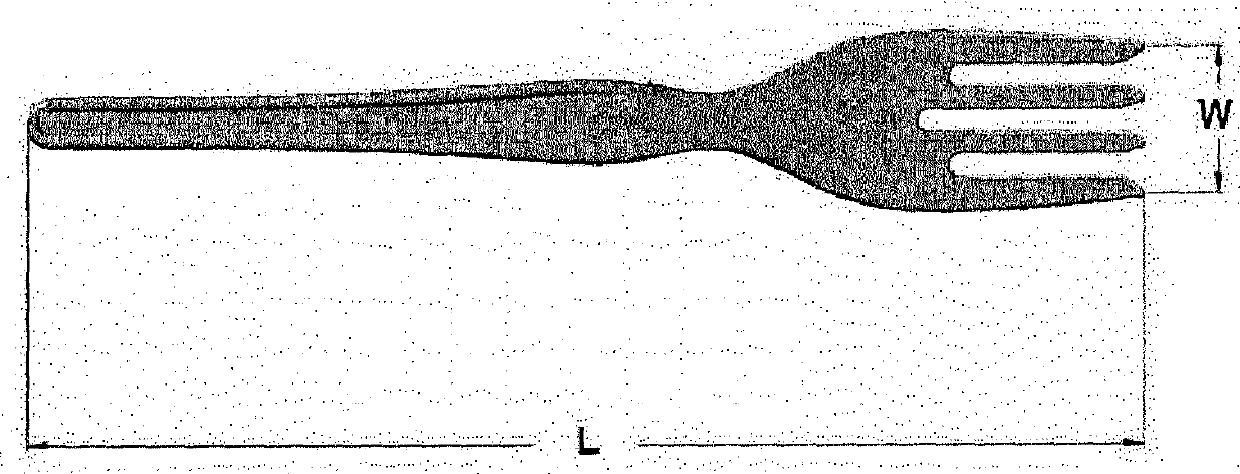

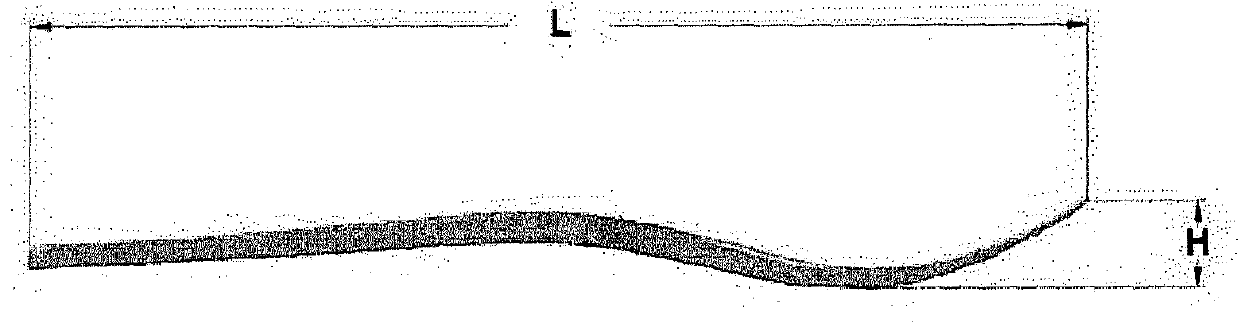

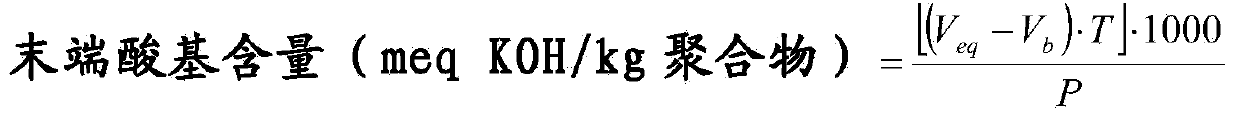

Image

Examples

Embodiment 1

[0114] Table 1 - Compositions in Example 1

[0115]

[0116] Values are expressed in parts when not explicitly indicated.

[0117] PLA = polylactic acid containing 98% L-lactic acid and 2% D-lactic acid, melting point Tm = 165°C, weight average molecular weight Mw = 166000, intrinsic viscosity = 0.97dl / g and shear viscosity = 120Pas, according to standard ASTM -D3835 at T=190℃, shear rate=1000s -1 Measured with capillary D=1 mm and L / D=10.

[0118] AAPE = poly(butylene sebacate-co-butylene terephthalate) (PBST) containing 56 mole % terephthalic acid relative to the total amount of aliphatic and aromatic diacids, And have MFI=14g / 10min (190 ℃ and 2.16kg), and shear viscosity η=570Pas, according to standard ASTM-D3835 at T=180 ℃, shear rate=104s -1 Measured with capillary D=1 mm and L / D=30.

[0119] Anti-caking agent = vegetable sourced oleamide

[0120] Nucleating agent = micronized talc (particle size = 2-10 microns)

Embodiment 2

[0142] The molded samples were then subjected to an annealing treatment in an unconfined environment in a Venti-Line VL115 model furnace with circulating air using the following operating conditions: temperature = 90°C, time = 60 minutes.

[0143] After cooling and further conditioning for 1 day at T=23° C. and 55% RH, the annealed specimens were then investigated to determine dimensional stability, mechanical properties and heat distortion temperature HDT.

[0144] The results of this characterization are shown in Tables 5-7.

Embodiment 3-5

[0146] The molded test pieces according to Example 1 were subjected to three different annealing treatments using the operating conditions shown in Table 3:

[0147] Table 3 - Annealing Conditions

[0148]

[0149] After cooling and reconditioning for 1 day at T=23°C and 55% RH, the annealed samples were studied to determine their dimensional stability (PDC) and heat deflection temperature (HDT) (Tables 6-7).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com