Single-axis variable-speed two-stage asynchronous heart pump with differential term iterative curve flow channel and its application method

A curved flow and heart pump technology, applied in blood pumps, circulatory assistance devices, suction devices, etc., can solve the problems of large pressure difference between the working surface and the back of the single-stage impeller blade, failure to consider the needs of different patients, blood cell destruction, etc. , to achieve the effect of favorable overall structure, convenient design, and reduced chance of hemolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

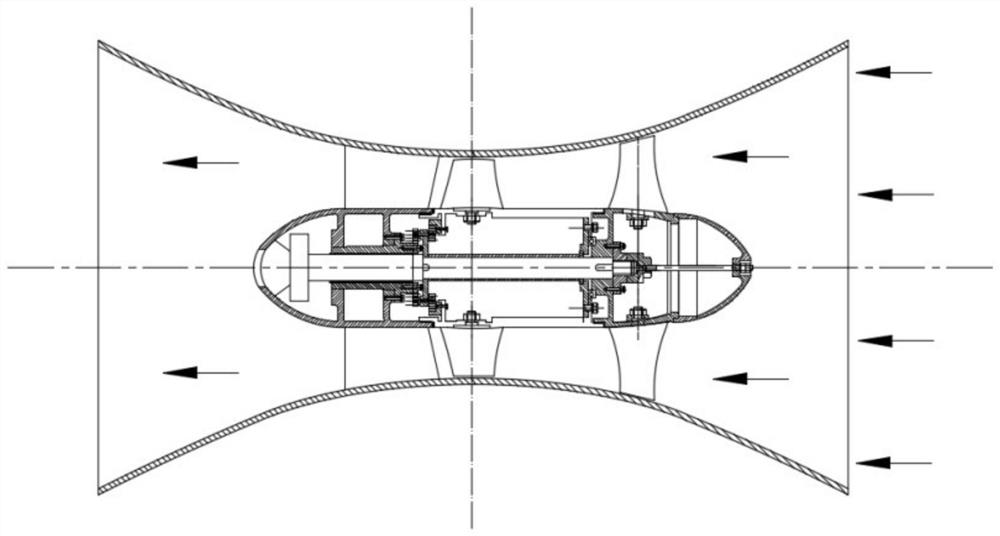

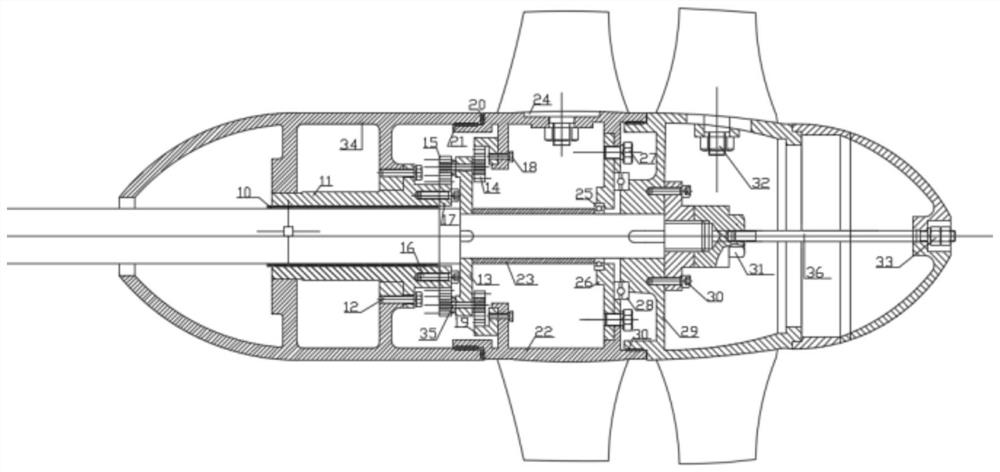

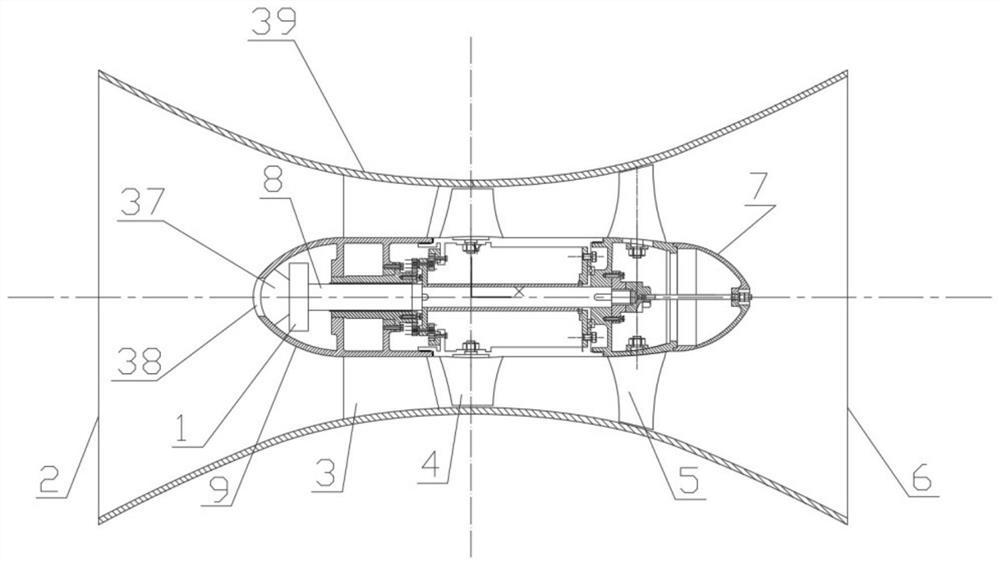

[0016] Example 1. The present invention proposes a uniaxial variable-speed two-stage asynchronous heart pump with a differential term iterative curve flow path, which includes a pump casing flow path 39 with a pump inlet 6 and a pump outlet 2, and a fixed guide is arranged in the pump casing flow path 39. The blade body 3, the first-stage impeller 5 and the second-stage impeller 4 are fixed on the transmission shaft 8 through a key; it also includes a DC permanent magnet motor 1 fixed on the inner side of the hub of the fixed guide vane body 3 through a shock absorber 37, The housing of the frequency sensor 38 is inlaid with the fixed guide vane hub tail 9 as a whole, the fixed guide vane body 3 is provided with a plurality of guide vane blades uniformly distributed around the x-axis, and the fixed guide vane body 3 passes through the guide vane The vane is fixed on the inner wall of the casing cavity of the pump casing flow channel 39;

[0017] The profile line of the casing...

Embodiment 2

[0024] Example 2. The present invention proposes a method for using a single-axis variable-speed two-stage asynchronous heart pump with a differential term iterative curved flow channel, which is characterized in that on the basis of the above-mentioned structure of the present invention, the DC permanent magnet motor 1 is connected by the transmission shaft 8 through the key The power is transmitted to the first-stage impeller 5; the transmission shaft 8 transmits the power to the planet carrier 13 through the key, the front planetary transmission gear 14 and the rear planetary transmission gear 15 are connected through the planetary transmission shaft 35, and the rear planetary transmission gear 15 and the hollow gear 17 meshes, the front planetary transmission gear 14 meshes with the ring gear 19, the ring gear 19 transmits the power to the second-stage impeller hub 22 through the fastening bolt 18, the front planetary transmission gear 14, the rear planetary transmission ge...

Embodiment 3

[0027] Example 3. The specific requirements for the component design, assembly and use of a single-axis variable-speed two-stage asynchronous heart pump proposed by the present invention are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com