Preparation method of high-efficiency polyether organic silicon defoaming agent applied under severe environment

A polyether organosilicon and organosilicon technology, applied in the direction of foam dispersion/prevention, can solve problems such as poor stability, and achieve the effect of stable process and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

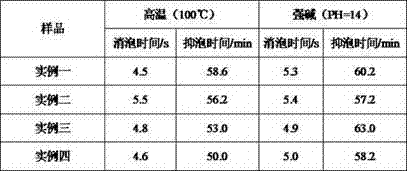

Examples

example 1

[0015] Example 1: The preparation of the polyether silicone mother liquor is to thoroughly dry the four-neck bottle and pass nitrogen gas for 10 minutes, mix 52 g of allyl polyoxyethylene polyoxypropylene with a molecular weight of about 1200 g / mol with 0.5 g of butyl acrylate and low hydrogen content Put 24g of silicone oil (hydrogen content 0.18%) into a four-neck flask with a stirrer with a thermometer, then raise the temperature to 85°C, add 0.10g of chloroplatinic acid / isopropanol solution dropwise as a catalyst (1g of chloroplatinic acid is dissolved in 50g isopropanol), react for 6-8 hours, and obtain a transparent polyether silicone mother liquor after the reaction. Stir the obtained polyether silicone mother liquor with 46.0g dimethyl silicone oil, 15.0g hydroxy silicone oil, 2.0g white carbon black (HB-630) at 120°C, 300rpm for 1h; then cool to 80°C, add 9.0g OP-10 , 8.0g Span 80 and stirred for 0.5h, and at the same time, 220g of water was added and stirred evenly t...

example 2

[0016] Example 2: The preparation of the polyether silicone mother liquor is to thoroughly dry the four-neck bottle and pass nitrogen gas for 10 minutes, mix 50 g of allyl polyoxyethylene polyoxypropylene with a molecular weight of about 2400 g / mol and 3.0 g of double bond single-blocked polyurethane acrylic acid Ester macromer and low hydrogen-containing silicone oil 7.5g (hydrogen content 0.12%) are put into the four-necked bottle of the stirrer with thermometer, then be warmed up to 80 o C. Add dropwise 0.06g chloroplatinic acid / isopropanol solution as a catalyst (1g chloroplatinic acid dissolved in 50g isopropanol), react for 6-8 hours, and obtain a transparent polyether silicone mother liquor after the reaction. Stir the obtained polyether silicone mother liquor with 40.0g dimethyl silicone oil, 15.0g hydroxy silicone oil, 1.5g white carbon black (HB-630) at 100°C, 300rpm for 1h; then cool to 80°C, add 8.0g OP-10 , 7.0g Tween 80 and stirred for 0.5h, and at the same time,...

example 3

[0017] Example 3: The preparation of the polyether silicone mother liquor is to thoroughly dry the four-necked bottle and pass nitrogen gas for 10 minutes, mix 50 g of allyl polyoxyethylene polyoxypropylene with a molecular weight of about 1200 g / mol with 1.0 g of hydroxyethyl acrylate and low content Put 20g of hydrogen silicone oil (hydrogen content 0.18%) into a four-neck flask with a stirrer with a thermometer, then heat up to 80°C, add dropwise 0.16g of chloroplatinic acid / isopropanol solution as a catalyst (1g of chloroplatinic acid dissolved in 50g isopropanol), react for 6-8h, and the transparent polyether silicone mother liquor is obtained after the reaction is completed. Stir the obtained polyether silicone mother liquor with 40.0g dimethyl silicone oil, 15.0g hydroxy silicone oil, 1.5g white carbon black (HB-630) at 100°C, 300rpm for 1h; then cool to 80°C, add 8.0g OP-10 , 7.0g Span 80, stirred for 0.5h, and at the same time, added 200g of water and stirred evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com