Fully synthetic anti-micropitting wind power gear oil composition and preparation method thereof

A technology of anti-micropitting and composition, applied in the field of lubricating oil, can solve the problems of low life and poor performance of wind power gear oil composition, and achieve the effects of improving solubility, good resistance to micropitting and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

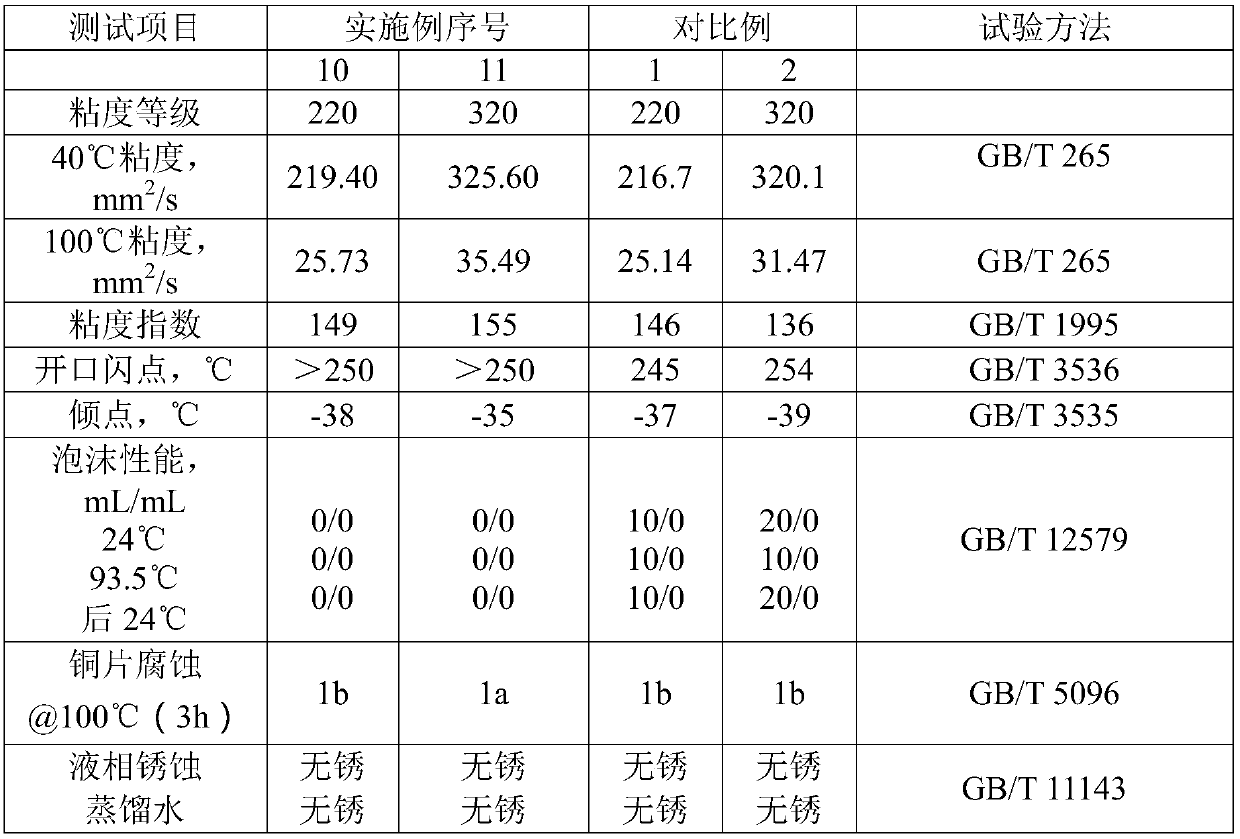

Examples

Embodiment 1

[0028] A fully synthetic anti-micropitting wind power gear oil composition of the present invention, the wind power gear oil composition comprises 1% of extreme pressure agent, 0.5% of anti-wear agent, 0.5% of antioxidant, and rust inhibitor by mass percentage. 0.1%, metal deactivator 0.1%, anti-emulsifier 0.1%, anti-foaming agent 0.02%, and the balance is base oil.

[0029] The base oil is a mixture of polyalphaolefin base oil and ester base oil, wherein the polyalphaolefin base oil adopts a mixture of low-viscosity PAO8 and high-viscosity PAO40 with excellent performance, and the mass ratio of the two is controlled to be 8: 75, the base oil has a high viscosity index, and the polyalphaolefin also makes the thermal evaporation loss of the wind turbine gear oil small; the ester base oil uses saturated polyol ester, which can make the oil compatible with the sealing material in the wind turbine gearbox . In this example, the mass ratio of polyalphaolefin base oil and ester bas...

Embodiment 2

[0034] A fully synthetic anti-micro-pitting wind power gear oil composition of the present invention, the wind power gear oil composition comprises, by mass percentage, 1% of an extreme pressure agent, 0.8% of an anti-wear agent, 0.5% of an antioxidant, and a rust inhibitor. 0.1%, metal deactivator 0.1%, anti-emulsifier 0.1%, anti-foaming agent 0.03%, and the balance is base oil.

[0035] The base oil is a mixture of polyalphaolefin base oil and ester base oil, wherein the polyalphaolefin base oil adopts a mixture of low-viscosity PAO8 and high-viscosity PAO40 with excellent performance, and the mass ratio of the two is controlled to be 8: 75, which makes the base oil have a higher viscosity index, and the polyalphaolefin also makes the thermal evaporation loss of the wind power gear oil small; the ester base oil adopts saturated polyol ester, which can make the oil and the sealing material in the wind power gear box compatible. Allow. In this example, the mass ratio of polya...

Embodiment 3

[0040] A fully synthetic anti-micro-pitting wind power gear oil composition of the present invention, the wind power gear oil composition comprises, by mass percentage, 1% of an extreme pressure agent, 2% of an anti-wear agent, 0.5% of an antioxidant, and a rust inhibitor. 0.1%, metal deactivator 0.1%, anti-emulsifier 0.3%, anti-foaming agent 0.03%, and the balance is base oil.

[0041] The base oil is a mixture of polyalphaolefin base oil and ester base oil, wherein the polyalphaolefin base oil adopts a mixture of low-viscosity PAO8 and high-viscosity PAO40 with excellent performance, and the mass ratio of the two is controlled to be 8: 75, which makes the base oil have a higher viscosity index, and the polyalphaolefin also makes the thermal evaporation loss of the wind power gear oil small; the ester base oil adopts saturated polyol ester, which can make the oil and the sealing material in the wind power gear box compatible. Allow. In this example, the mass ratio of polyalp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com