Litsea cubeba oil mildew and moth proof slow release microcapsule and preparation method

A technology of slow-release microcapsules and litsea cubeba oil, which is applied in botany equipment and methods, pest control, chemicals for biological control, etc., can solve the problems of not having slow-release properties, and achieve the convenience of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

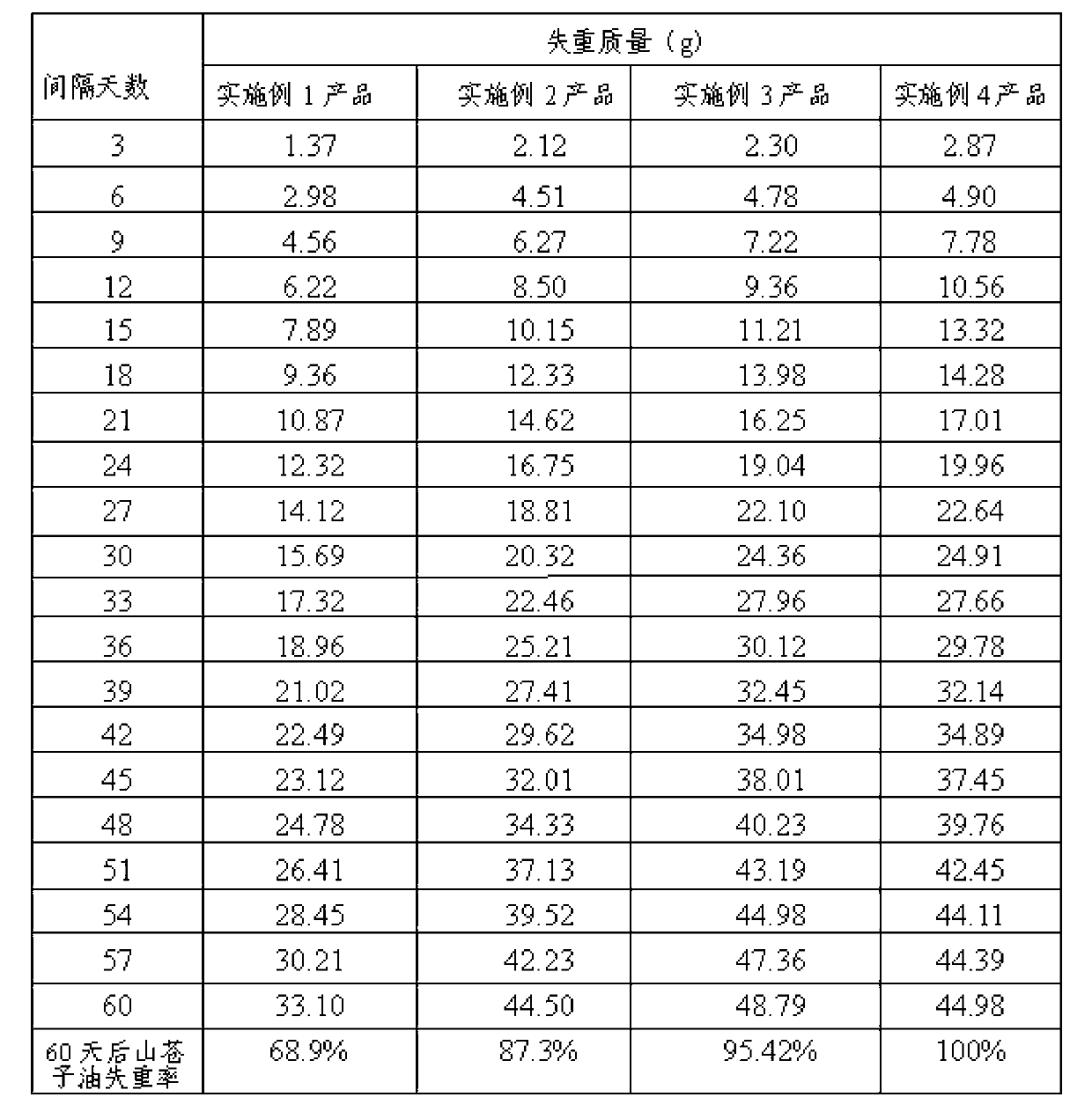

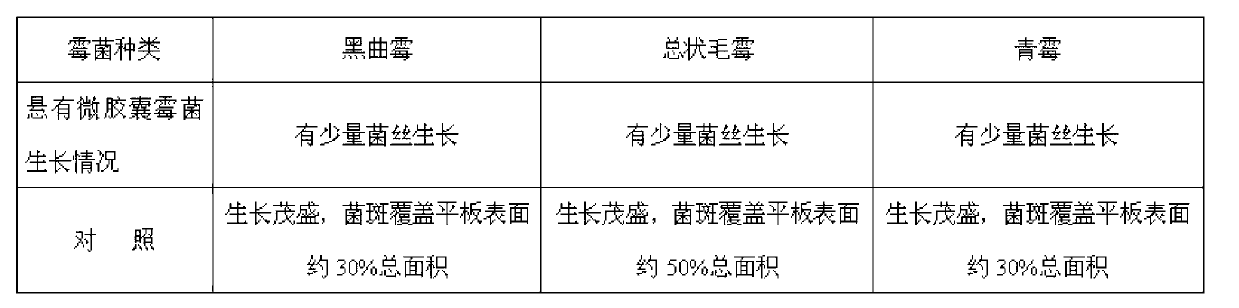

Examples

Embodiment 1

[0028] 1) Add 10g of N-methylpyrrolidone to 100g of ethyl cellulose, heat to 90°C, stir to dissolve, and obtain ethyl cellulose viscous liquid;

[0029] 2) Heat 650g of water to 90°C, add 100g of high-substituted hydroxypropyl cellulose, 60g of gum arabic, and 20g of maltodextrin under stirring until all are dissolved, add the above ethyl cellulose viscous liquid, and stir at 90°C for 40 minute, cooled to room temperature, added emulsifier containing 2g Span80 and 2g Tween80 and 100g litsea cubeba oil under stirring, and dispersed at a high speed of 1000 rpm to obtain litsea cubeba oil emulsion;

[0030] 3) The above emulsion is homogenized in the first stage at 30MPa, and in the second stage at 5MPa, and then spray-dried at a feed rate of 25g / min, an inlet air temperature of 195°C, and an outlet air temperature of 90°C to obtain a slow-release Litsea cubeba oil anti-mildew and anti-moth slow-release microcapsules. The prepared litsea cubeba oil microcapsules had an effective...

Embodiment 2

[0032] 1) Add 15g of N-methylpyrrolidone to 100g of ethyl cellulose, heat to 90°C, stir to dissolve, and obtain ethyl cellulose viscous liquid;

[0033] 2) Heat 700g of water to 90°C, add 50g of high-substituted hydroxypropyl cellulose, 50g of gum arabic, and 50g of maltodextrin under stirring until all of them are dissolved, add the above ethyl cellulose viscous liquid, and stir at 90°C for 30 minute, cooled to room temperature, added emulsifier containing 2g Span80 and 2g Tween80 and 100g litsea cubeba oil under stirring, and dispersed at a high speed of 900 rpm to obtain litsea cubeba oil emulsion;

[0034]3) The above-mentioned emulsion is homogenized in the first stage at 30MPa, and in the second stage at 5MPa, and then spray-dried at a feed rate of 20g / min, an inlet air temperature of 180°C, and an outlet air temperature of 85°C to obtain a slow-release Litsea cubeba oil anti-mildew and anti-moth slow-release microcapsules. The effective oil loading capacity of the obta...

Embodiment 3

[0036] 1) Add 12g of N-methylpyrrolidone to 100g of ethyl cellulose, heat to 90°C, stir to dissolve, and obtain ethyl cellulose viscous liquid;

[0037] 2) Heat 600g of water to 90°C, add 60g of high-substituted hydroxypropyl cellulose, 20g of gum arabic, and 20g of maltodextrin under stirring until all of them are dissolved, add the above ethyl cellulose viscous liquid, and stir at 90°C for 20 minute, cooled to room temperature, added emulsifier containing 1g Span80 and 1g Tween80 and 100g litsea cubeba oil under stirring, and dispersed at a high speed of 800 rpm to obtain litsea cubeba oil emulsion;

[0038] 3) The above emulsion is homogenized in the first stage at 30MPa, and in the second stage at 5MPa, and then spray-dried at a feed rate of 15g / min, an inlet air temperature of 165°C, and an outlet air temperature of 75°C to obtain a slow-release Litsea cubeba oil anti-mildew and anti-moth slow-release microcapsules. The prepared litsea cubeba oil microcapsules had an eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com