SnO2, MnO or Mn3O4-based composite material based on three-dimensional carbon sphere framework structure and preparation method of material

A frame structure and composite material technology, applied in structural parts, electrical components, electrochemical generators, etc., can solve the problems of difficult to maintain long-life cycles, short-circuit safety of lithium dendrites, low conductivity, etc., to achieve superior cycle performance and Rate performance, good lithium ion diffusion coefficient, simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

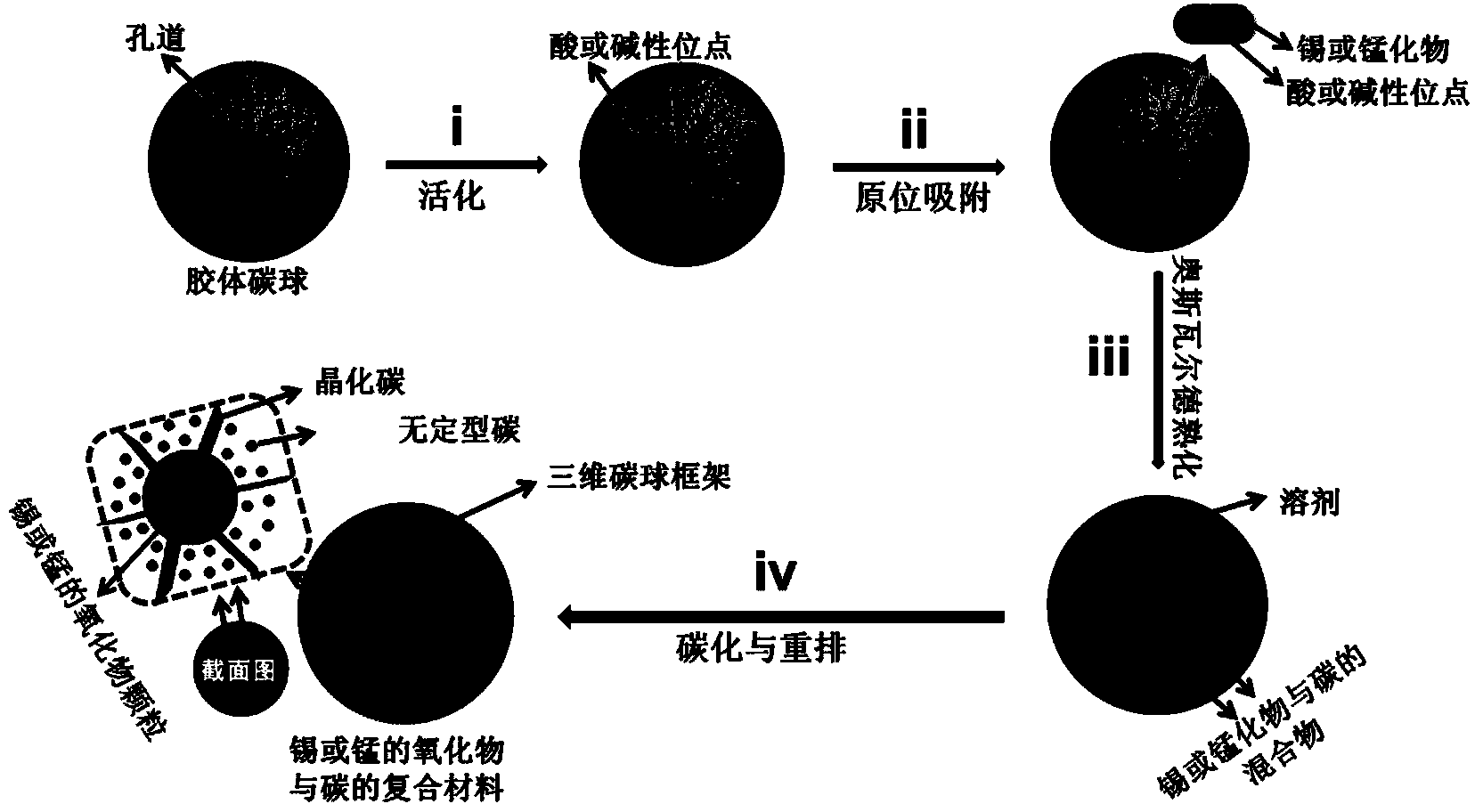

Method used

Image

Examples

Embodiment 1

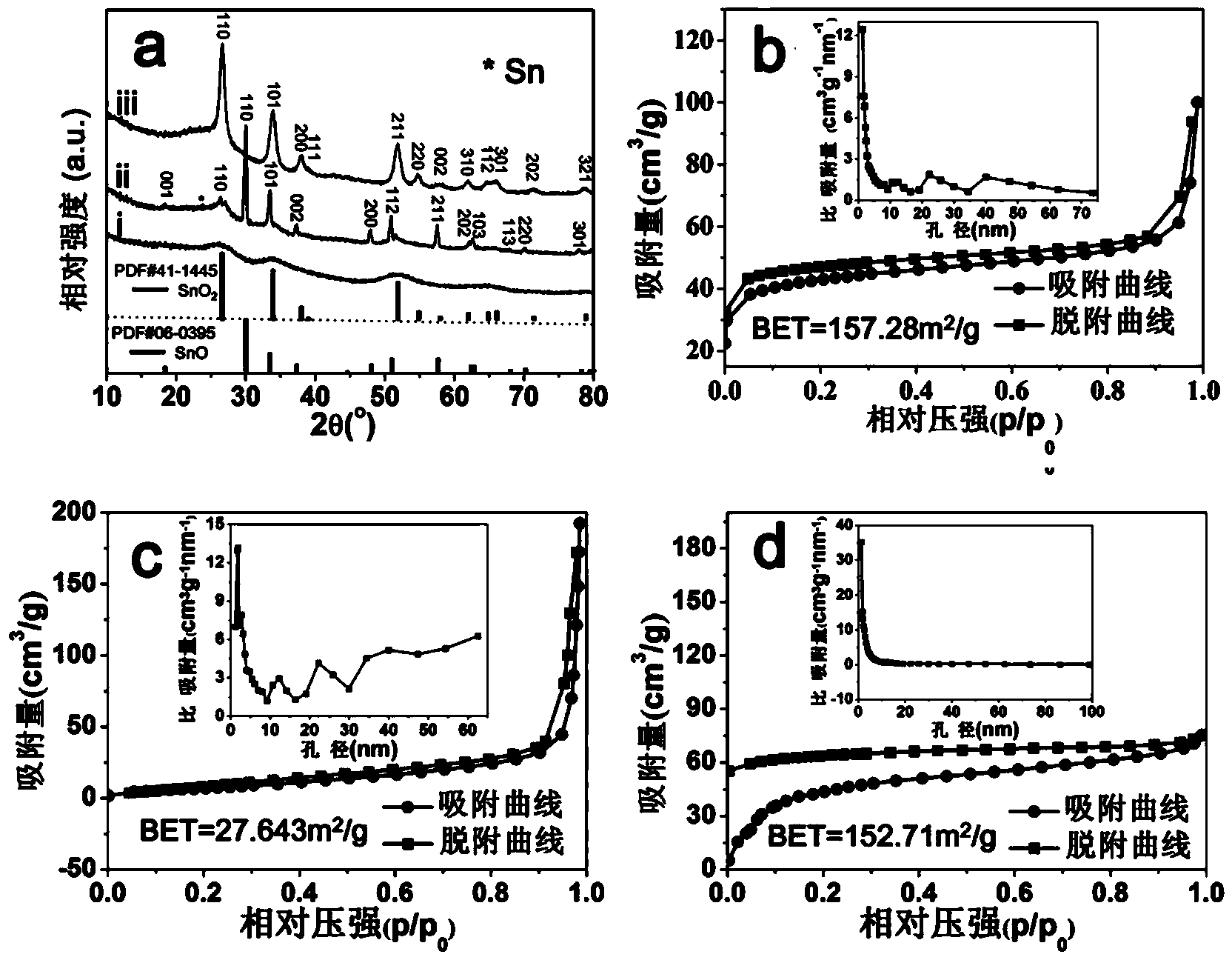

[0047] This example prepares SnO 2 With the composite material of carbon, its method step is as follows:

[0048] (1) Preparation of colloidal carbon spheres: put 70mL of 1.2M (1M=1mol / L) glucose aqueous solution in a hydrothermal reaction kettle with a capacity of 100mL and react at 180°C for 5 hours, wash and centrifuge the product to obtain brown-black colloidal carbon spheres; other conditions remain unchanged, the morphology of colloidal carbon spheres prepared by replacing 1.2M glucose aqueous solution with 1.8M glucose aqueous solution and 0.5M sucrose aqueous solution is shown in Figure 22 .

[0049] (2) Preparation of activated colloidal carbon spheres: Weigh 1g of the colloidal carbon spheres prepared in the above step (1), add them to 80mL of 1M HCl, activate them at 100°C under normal pressure for 12h, and wash and dry the obtained product to obtain Acid activated colloidal carbon spheres. SEM test shows that the carbon spheres are uniform microspheres with a d...

Embodiment 2

[0061] This embodiment prepares the composite material of MnO and carbon, and its method step is as follows:

[0062] (1) Preparation of colloidal carbon spheres: put 70mL of 1.8M glucose aqueous solution in a hydrothermal reactor with a capacity of 100mL and react at 180°C for 5 hours, wash and centrifuge the product to obtain brown-black colloidal carbon spheres;

[0063] (2) Preparation of activated colloidal carbon spheres: Weigh 1g of the colloidal carbon spheres prepared above, add 80mL 1MNH 3 ·H 2 In O, activation treatment at 100°C under normal pressure for 12 hours, after washing and drying the obtained product, the alkaline activated colloidal carbon spheres can be obtained;

[0064] (3) Preparation of composite materials of MnO and carbon: Weigh 0.3g of alkaline activated colloidal carbon spheres prepared above, add to 0.5M MnCl 2 In 80mL ethanol aqueous solution system (the volume ratio of water and ethanol is 1:1), the reaction was carried out in a water bath at...

Embodiment 3

[0068] This example prepares SnO 2 With the composite material of carbon, its method step is as follows:

[0069] (1) Preparation of colloidal carbon spheres: put 70mL of 0.5M sucrose aqueous solution in a hydrothermal reactor and react at 130°C for 12 hours, wash and centrifuge the resultant to obtain brown-black colloidal carbon spheres;

[0070] (2) Preparation of activated colloidal carbon spheres: Weigh 1g of the colloidal carbon spheres prepared above, add 80mL 0.1M HNO 3 , activated under normal pressure at 50°C for 24 hours, and after washing and drying the obtained product, acidic activated colloidal carbon spheres can be obtained;

[0071] (3) Preparation of SnO 2 Composite material with carbon: Weigh 0.3g of acid activated colloidal carbon spheres prepared above, add to 2 and 0.2M SnCl 4 In 80mL ethanol aqueous solution system (the volume ratio of water and ethanol is 1:5), react in a water bath at 90°C for 3h, and the process is completed under constant stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com