Concrete processing equipment

A technology for processing equipment and concrete, which is applied to clay preparation devices, solid separation, filtration and screening, etc. It can solve problems such as unsatisfactory demands, and achieve the effects of saving resources, fully mixing, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

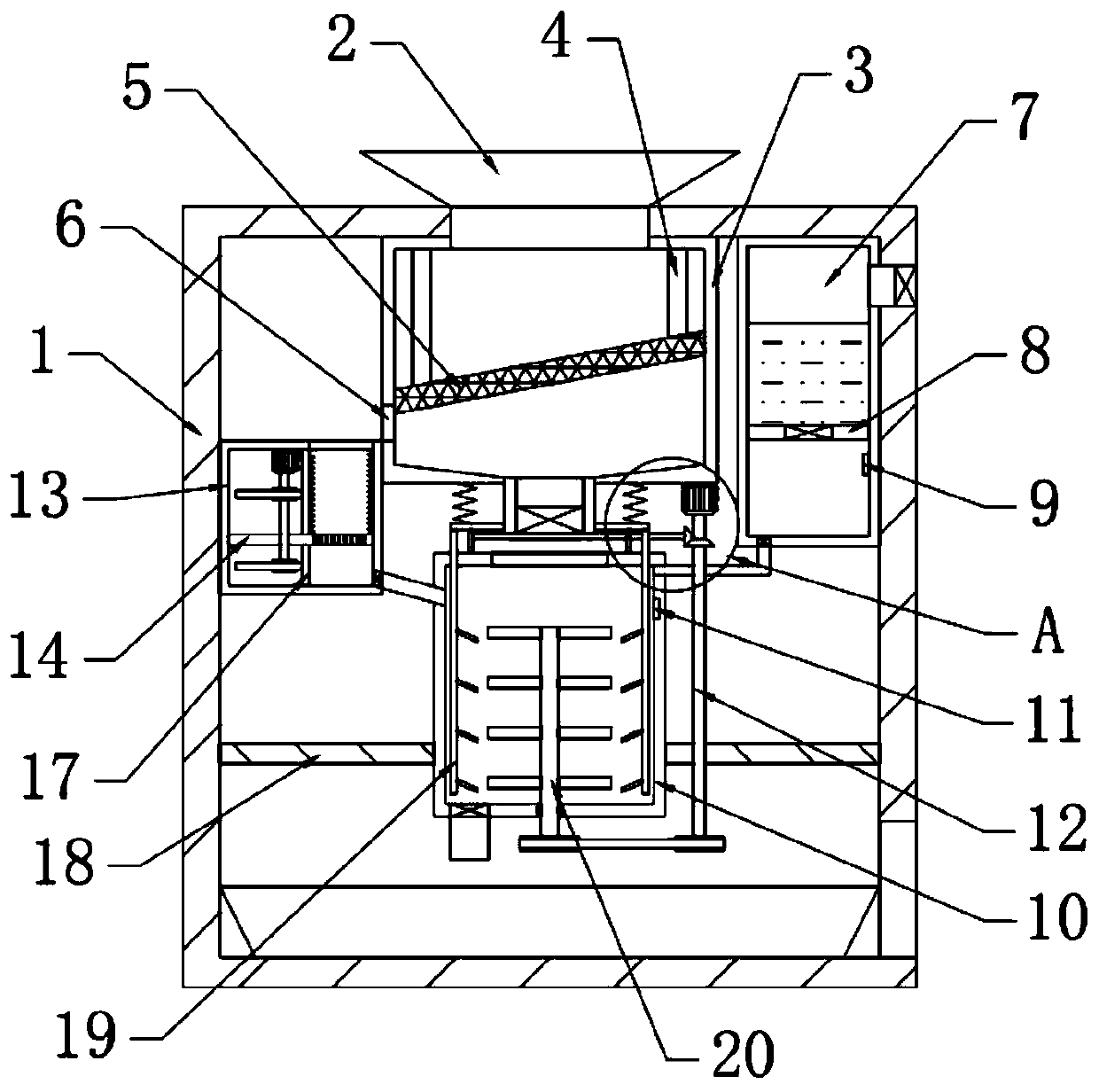

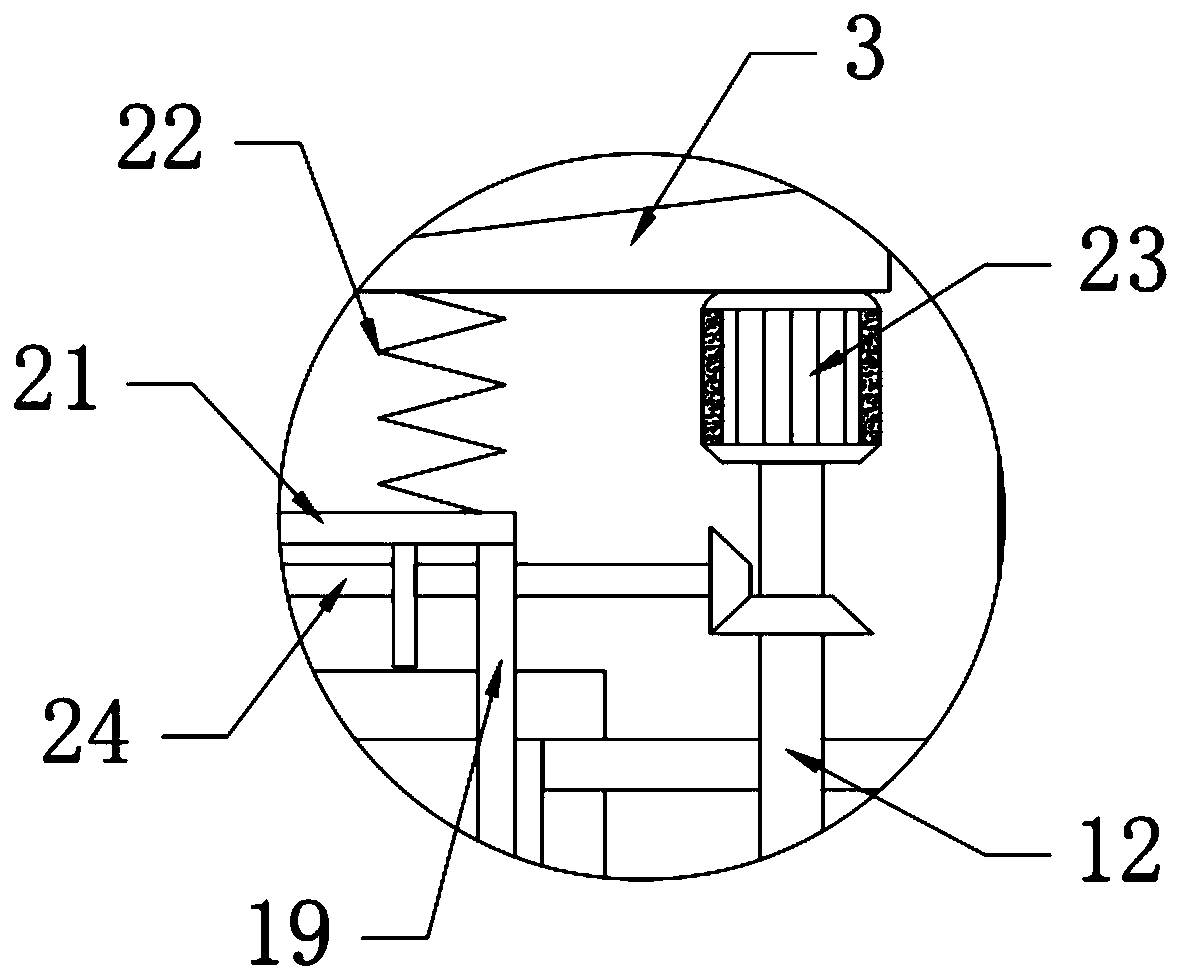

[0026] see Figure 1~3 , in an embodiment of the present invention, a concrete processing equipment includes a casing 1, a feed hopper 2 is arranged on the top of the casing 1, a screen box 3 is arranged on the lower side of the feed hopper 2, and the screen box 3 It is fixedly connected with the housing 1, the left side of the screen box 3 is provided with a gravel processing mechanism fixedly connected with the housing 1, and the lower side of the screen box 3 is provided with a fixed plate 18 fixedly connected with the housing 1. A mixing bucket 10 is fixedly connected on the fixed plate 18, and the mixing bucket 10 is connected with the gravel processing mechanism through a conduit. Connected by a water inlet pipe, a material storage box is provided on the lower side of the mixing bucket 10 .

Embodiment 2

[0028] In this embodiment, a sieve plate 5 is installed obliquely on the inner side of the sieve box 3, and the sieve plate 5 is slidingly connected with the sieve box 3. The vibrating rod 4 that moves repeatedly, the other end of the vibrating rod 4 is fixedly connected with the screen box 3, the left side of the screen box 3 is provided with a discharge port 6, and the bottom of the screen box 3 is fixedly connected with a discharge port. The sieve box 3 is provided to screen impurities such as crushed stones in the raw materials, so that the raw materials falling into the mixing tank 10 are finer sand, which is beneficial to improve the quality of the concrete produced.

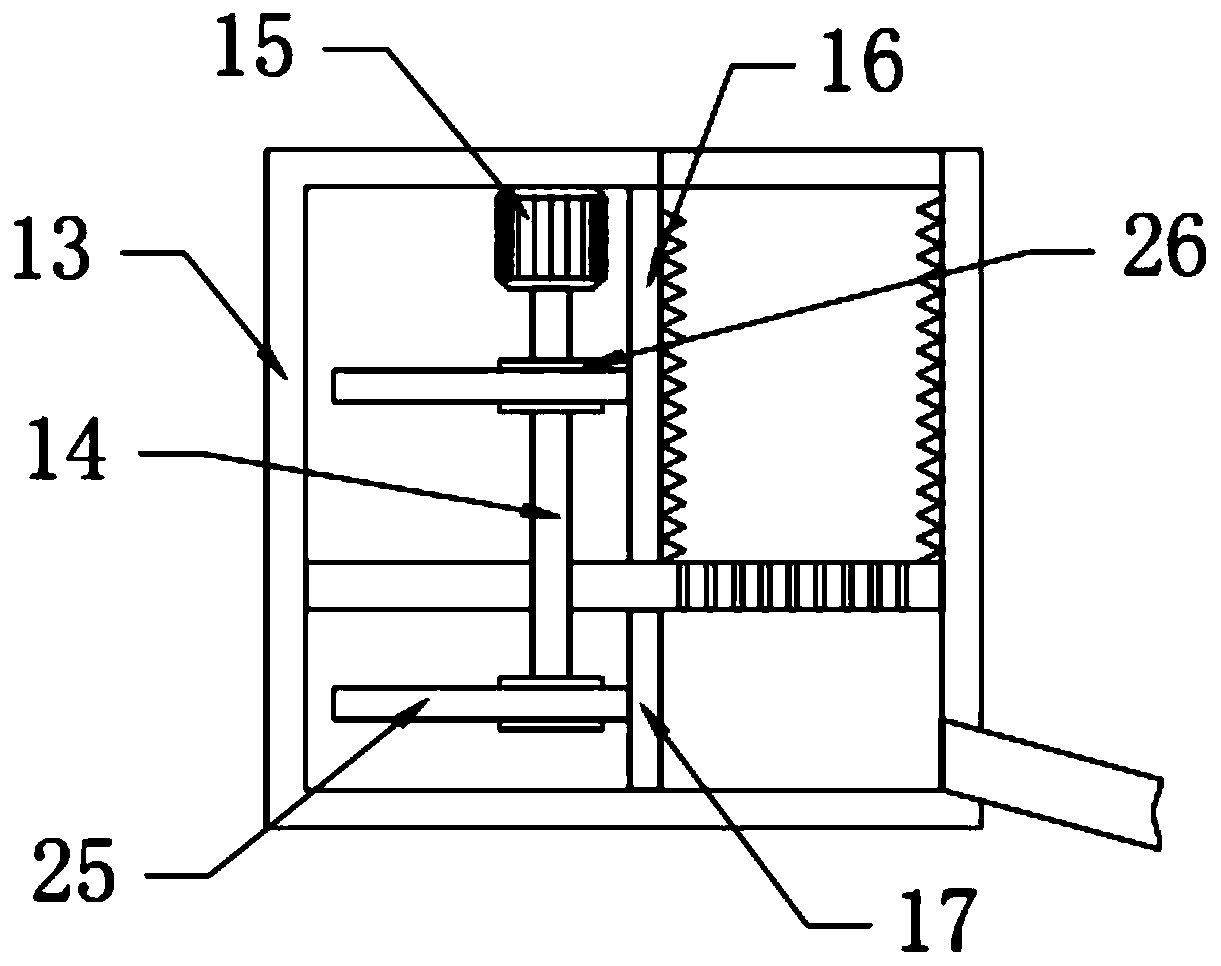

[0029] In this embodiment, the gravel processing mechanism includes a casing 13, a horizontal plate 14, a pressing plate 16 and a push plate 17, the casing 13 is arranged on the left side of the screen box 3, the casing 13 is fixedly connected with the casing 1, and the The inner side of the casing 13 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com