Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

A functionally graded material, laser rapid prototyping technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of uneven powder mixing, difficulty in forming functionally graded materials, and more powder waste, and reduce subsequent processing. , The powder feeding is uniform and easy to control, and the effect of avoiding agglomeration and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

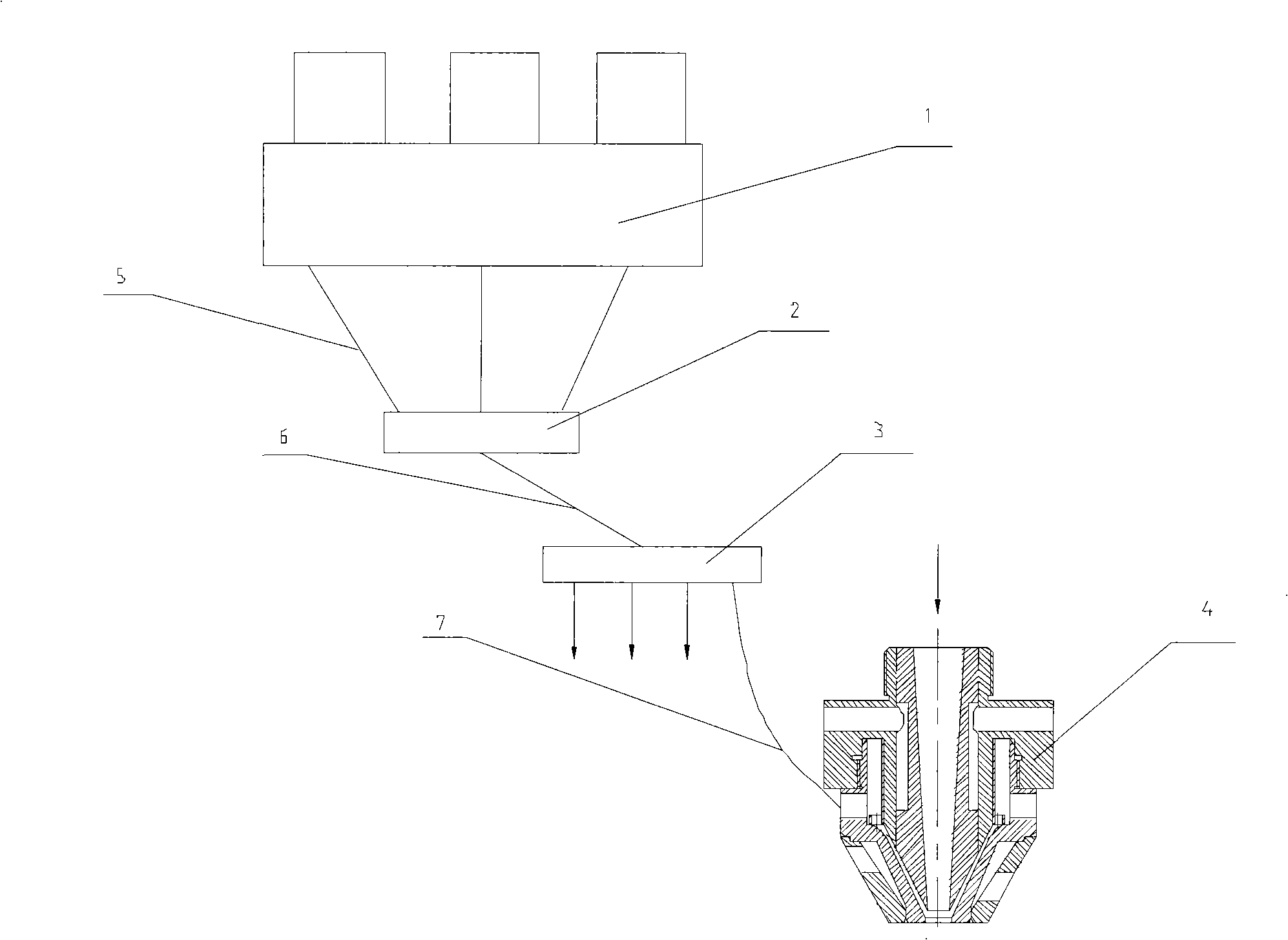

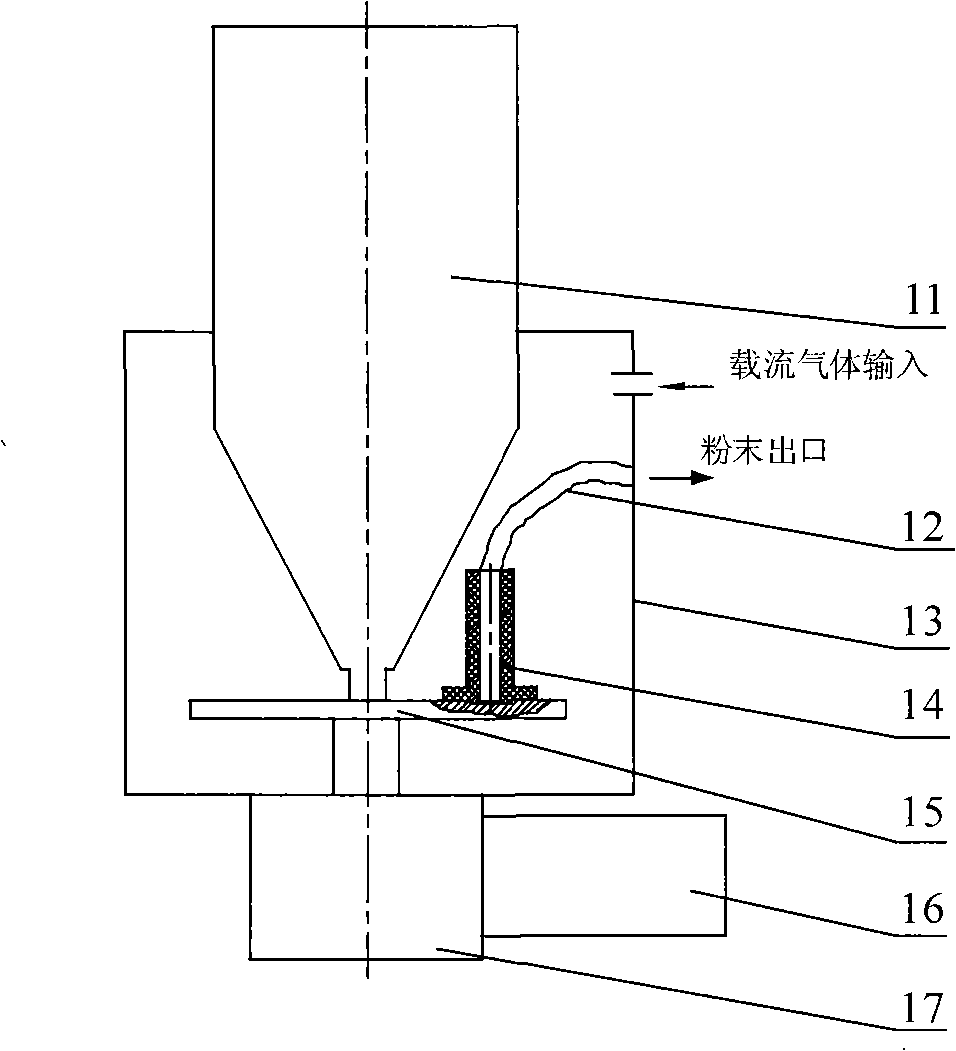

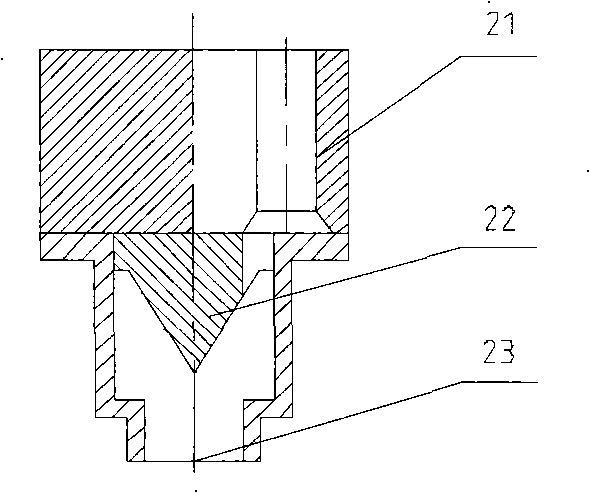

[0023] The present invention is a system for preparing functionally graded materials through laser rapid prototyping technology. By improving the powder delivery system of the laser rapid prototyping system, it can transport more than two kinds of powder materials at the same time, and the ratio of different powder materials can be adjusted according to needs. control. In order to be able to realize the quantitative feeding, mixing, powder distribution and spray cladding of alloy powder in the process of laser rapid prototyping, such as figure 1 As shown, the system of the present invention mainly consists of five parts: a powder feeder 1, a powder mixer 2, a powder separator 3, a nozzle 4 and a control device. Among them, the powder feeder 1 sucks and transmits the powder through the carrier gas, and its powder outlet communicates with the three inlets of the powder mixer through the first conveying pipe 5 (3 pieces); the powder mixer 2 feeds the powder into the powder feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com