Manufacture process of steel wire mesh framework composite pipe

A manufacturing process, steel mesh technology, applied in the field of polyethylene pipe manufacturing process, can solve the problems of low production efficiency, large investment in equipment, easy to fall off the resin layer, etc., and achieve the effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

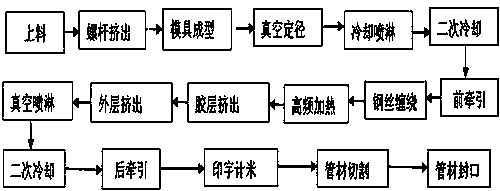

[0025] The steel mesh skeleton composite pipe manufacturing process provided by the invention comprises the following steps:

[0026] (1) Feeding: Add 2% black master particles to the main material of granular polyethylene to make the inner and outer polyethylene pipe raw materials of the steel mesh skeleton composite pipe, and put the raw materials into the inner polyethylene pipe screw extruder respectively and the hopper of the outer polyethylene pipe extruder;

[0027] (2) Extrusion molding of the inner layer polyethylene pipe: the inner layer polyethylene pipe screw extruder extrudes polyethylene into the inner layer polyethylene pipe mold to form the inner layer polyethylene pipe blank; the inner layer polyethylene pipe screw extrusion The machine is integrated with the inner polyethylene pipe mold;

[0028] (3) Vacuum sizing and cooling: quickly spray water vapor to the hole of the inner polyethylene pipe blank, so that the inner wall of the tube hole is rapidly cooled...

Embodiment 2

[0035] The steel mesh skeleton composite pipe manufacturing process provided by the invention comprises the following steps:

[0036] (1) Feeding: Add 2.5% black master particles to the main material of granular polyethylene to make the inner and outer polyethylene pipe raw materials of the steel mesh skeleton composite pipe, and put the raw materials into the inner polyethylene pipe screw extruder respectively and the hopper of the outer polyethylene pipe extruder;

[0037] (2) Extrusion molding of the inner layer polyethylene pipe: the inner layer polyethylene pipe screw extruder extrudes polyethylene into the inner layer polyethylene pipe mold to form the inner layer polyethylene pipe blank; the inner layer polyethylene pipe screw extrusion The machine is integrated with the inner polyethylene pipe mold;

[0038] (3) Vacuum sizing and cooling: quickly spray water vapor to the hole of the inner polyethylene pipe blank, so that the inner wall of the tube hole is rapidly cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com