Loudspeaker module

A loudspeaker module and loudspeaker technology, applied in the direction of sensors, electrical components, etc., can solve problems such as difficulty in ensuring consistency, long R&D cycle, and decline in acoustic performance, and achieve product consistency assurance, reduce labor costs, and improve operating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

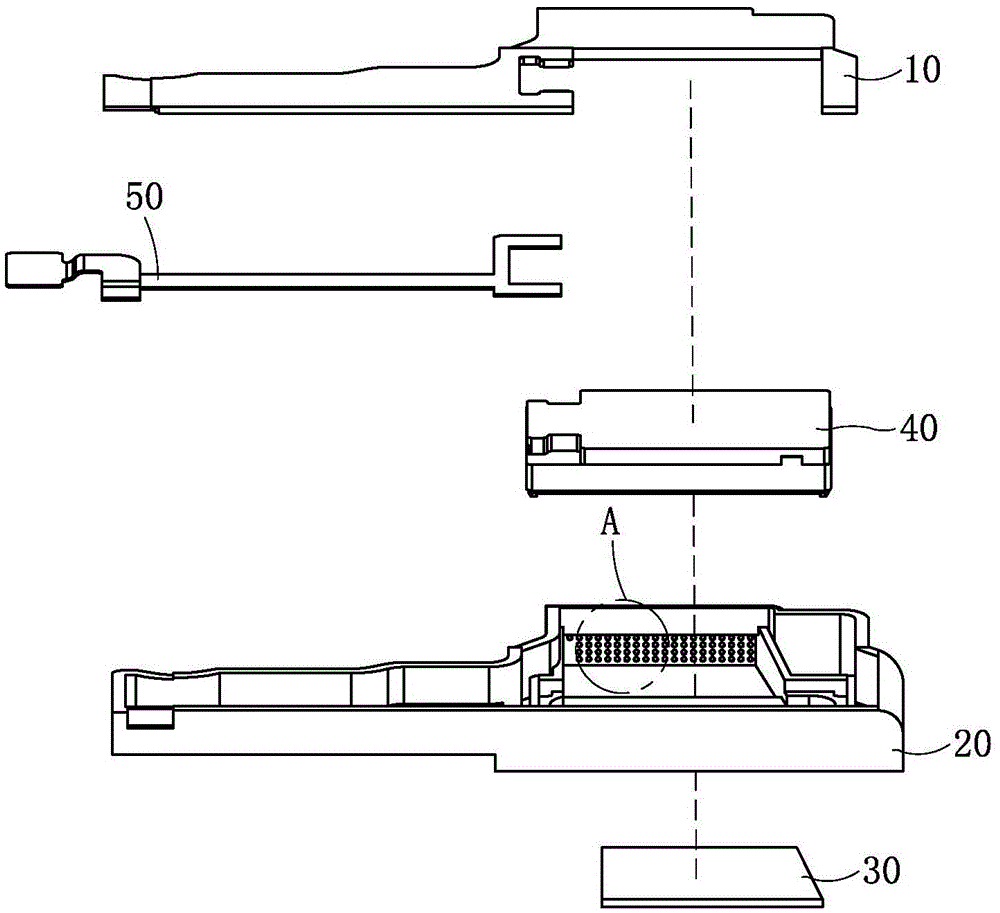

[0033] Such as figure 1 As shown, a speaker module includes a shell, and the shell is composed of a first shell 10, a second shell 20 and a third shell 30 combined together, the first shell 10, the second shell 20 and the third shell A speaker unit 40 is accommodated in the space surrounded by the three casings 30, and the speaker unit 40 divides the entire module inner cavity into two cavities, a front acoustic cavity and a rear acoustic cavity. The speaker unit 40 together with the first housing 10 and the second housing 20 forms a rear acoustic cavity, and the speaker unit 40 together with the second housing 20 and the third housing 30 forms a front acoustic cavity, corresponding to the position of the front acoustic cavity A sound output area 22 is provided on the body, and the sound emitted by the speaker unit 40 radiates outward from the sound output area 22 .

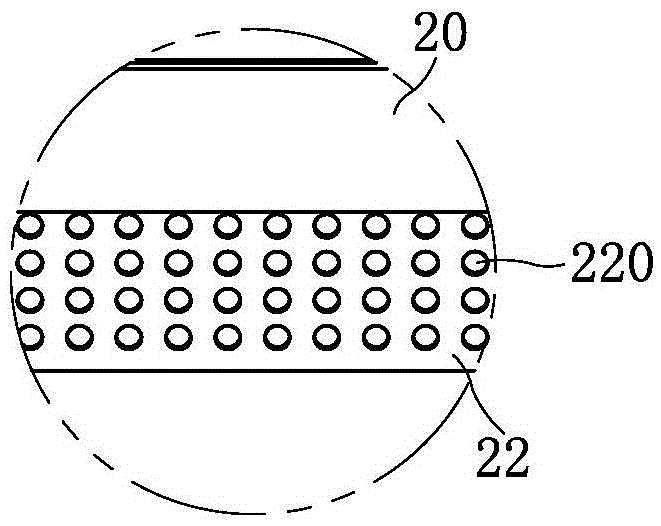

[0034] Such as figure 1 and figure 2 Commonly shown, the materials of the first shell 10 , the second shel...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, the difference is that:

[0044] Such as figure 1 and figure 2 As shown together, the sound emitting area 22 is made of a metal sheet, the microholes 220 are formed by laser drilling or stamping, and the metal sheet is bonded to the second housing 20 by bonding or injection molding. The metal sheet can be made of aluminum alloy, copper, steel, etc. In this embodiment, the metal sheet is preferably a steel sheet. During processing, the microholes 220 may be processed on the steel sheet first, and then the steel sheet with the microholes punched is bonded or injected onto the second shell 20 .

[0045] Compared with the first embodiment, this embodiment has a stronger heat dissipation capability of the front acoustic cavity and lower processing difficulty.

[0046] In the present invention, the sound output area of the loudspeaker module is set as a closed type, and the outward radiation of sound waves is realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com