Preparation method of bamboo cellulose

A technology of bamboo cellulose and bamboo, which is applied in the field of preparing bamboo cellulose by physical methods, can solve the problems of chemical pollution and high cost of bamboo cellulose, and achieve the effects of wide distribution, easy material acquisition, and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

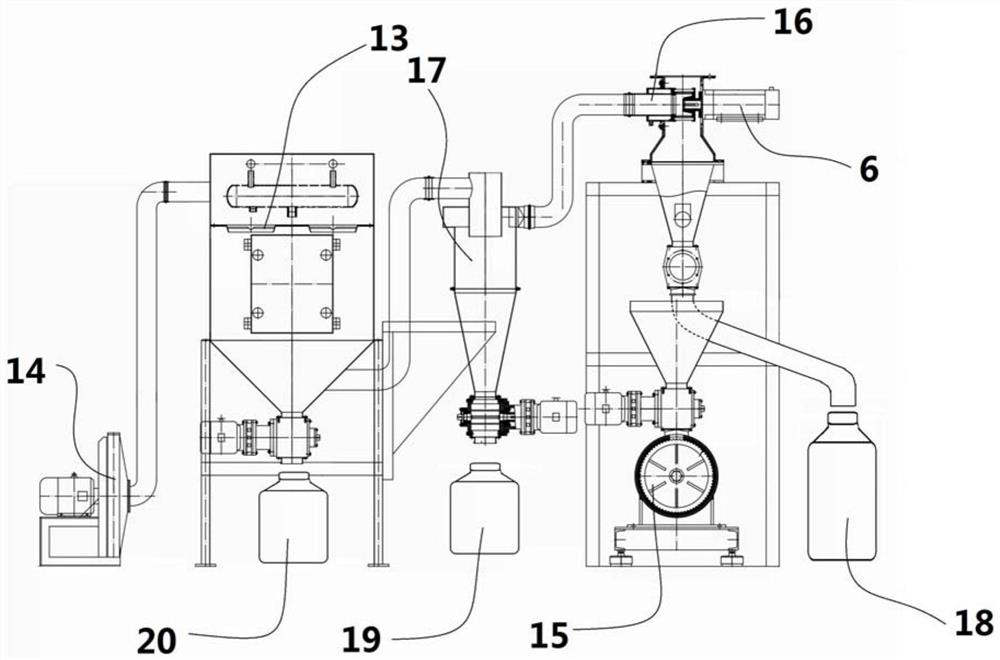

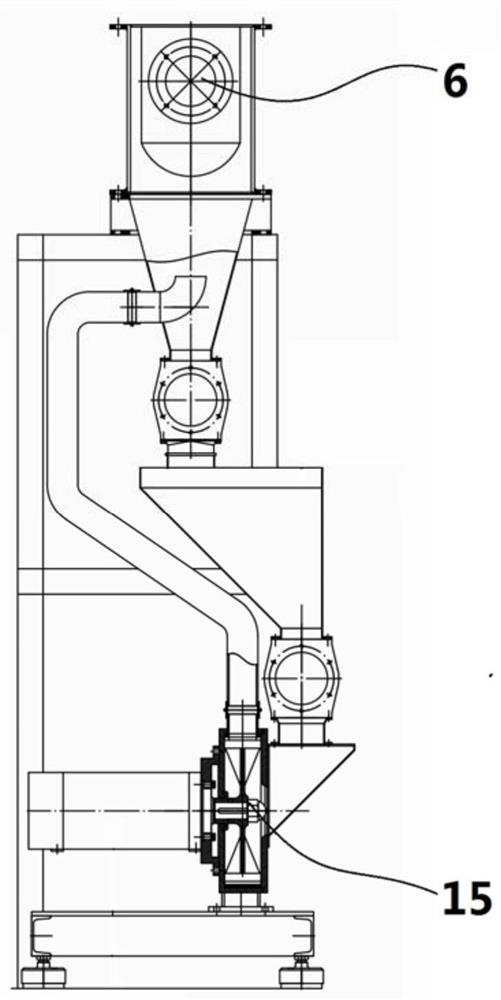

[0051] The preparation method of the bamboo cellulose that the embodiment of the present invention 1-4 provides, the cellulose extraction equipment that adopts adopts, as figure 1 Shown, including: cutting mechanism, crushing mechanism and screening mechanism.

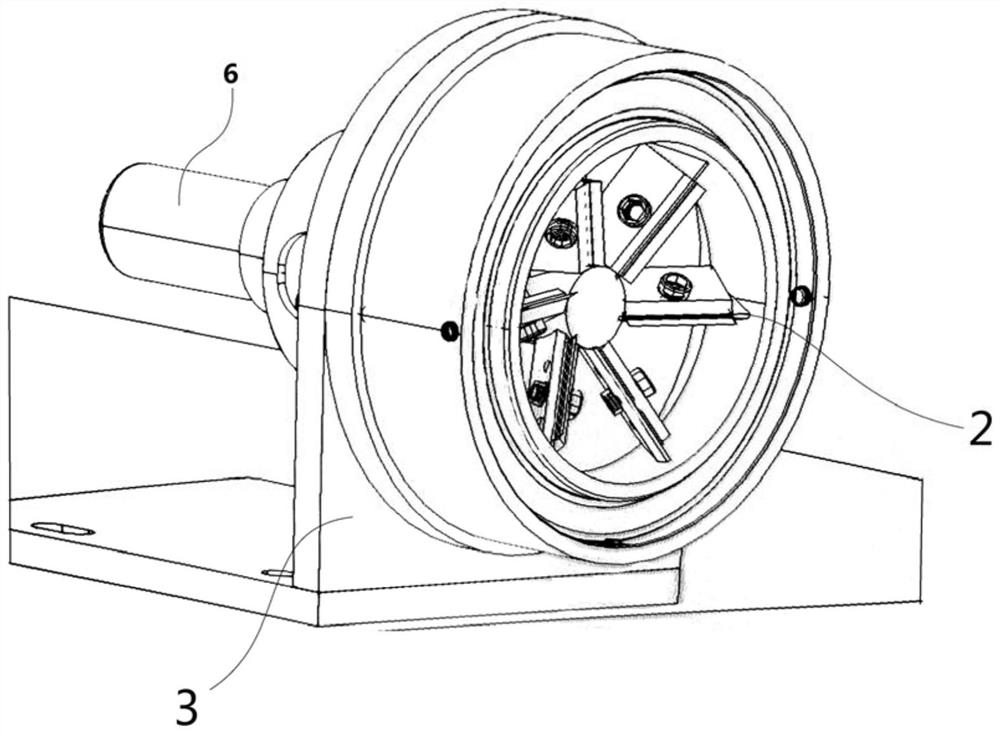

[0052] Specifically, the cutting mechanism has several blades 2 installed in rotation, and the blades 2 slice the end of the bamboo along the direction perpendicular to the growth direction of the bamboo. After the bamboo is cut into pieces, it is put into the hydrolysis device for hydrolysis. Such as image 3 As shown, the cutting mechanism includes a power element. In this embodiment, the power element is a high-speed separation motor 6, and a shaft coupling is installed on the output shaft of the high-speed separation motor. The other end of the coupling is connected with the tool holder, and the tool holder Installed on the frame body 3 through bearings, the knife rest has an annular outer ring, and several blade...

Embodiment 1

[0060] The bamboo in this embodiment is selected from green bamboos produced in Huaiji, Guangdong.

[0061] The present embodiment provides a kind of preparation method of bamboo cellulose, comprises the following steps:

[0062] S1, with length 1.8m, the bamboo that outer diameter is 50mm carries out rotary cutting along cross section (being the plane perpendicular to bamboo growth direction), is cut into the bamboo sheet 21 that thickness is 0.05mm, the length-to-diameter ratio of the bamboo fiber 1 of bamboo Greatly reduced.

[0063] S2. Import the cut bamboo flakes 21 into the extraction tank 4 filled with water, the water temperature is 70°C, the weight ratio of bamboo flakes to water is 1:4, the ultrasonic power is 1500W, the ultrasonic frequency is 40KHz, and the ultrasonic time is 45 minutes.

[0064] After the ultrasonic hydrolysis is completed, it is copied out with a gauze, after two times of clean water washing, it is placed in a centrifuge to filter the water, an...

Embodiment 2

[0068] The present embodiment provides a kind of preparation method of bamboo cellulose, and bamboo is selected from the green bamboo that Guangdong Huaiji area produces, comprises the following steps:

[0069] S1. The bamboo with a length of 1.8m and an outer diameter of 50mm is rotary cut along the cross section (ie, the surface perpendicular to the bamboo axis), and cut into thin bamboo slices 21 with a thickness of 0.05mm.

[0070] S2. Import the cut bamboo flakes 21 into the extraction tank 4 filled with water, the water temperature is 50°C, the weight ratio of bamboo flakes to water is 1:3, the ultrasonic power is 900W, the ultrasonic frequency is 30KHz, and the ultrasonic time is 50 minutes.

[0071] After the ultrasonic hydrolysis is completed, take it out with gauze, wash it twice with clean water, place it in a centrifuge to filter the water, and then dry it in an oven at 70°C for 8 hours to take it out. At this time, the water content is 3%.

[0072] S3. The solid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com