Edge starching device and dyeing and finishing method of fabric

A technology for sizing and fabrics, applied in the direction of dyeing method, textile material processing, continuous processing of textile materials, etc., can solve the problems of cloth end spinning, scrap fabrics, etc., achieve soft gloss, improve product qualification rate, and smooth cloth surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

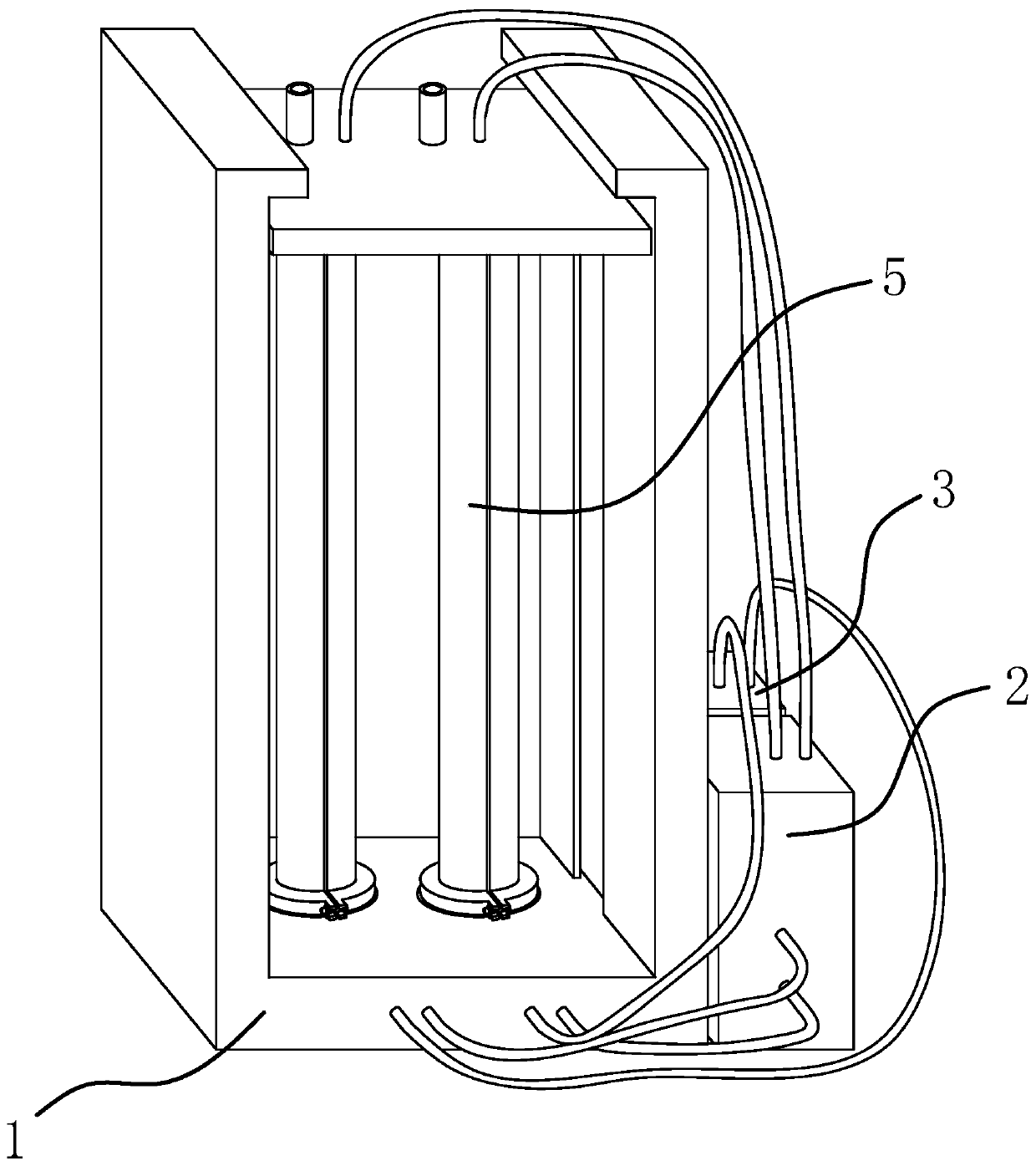

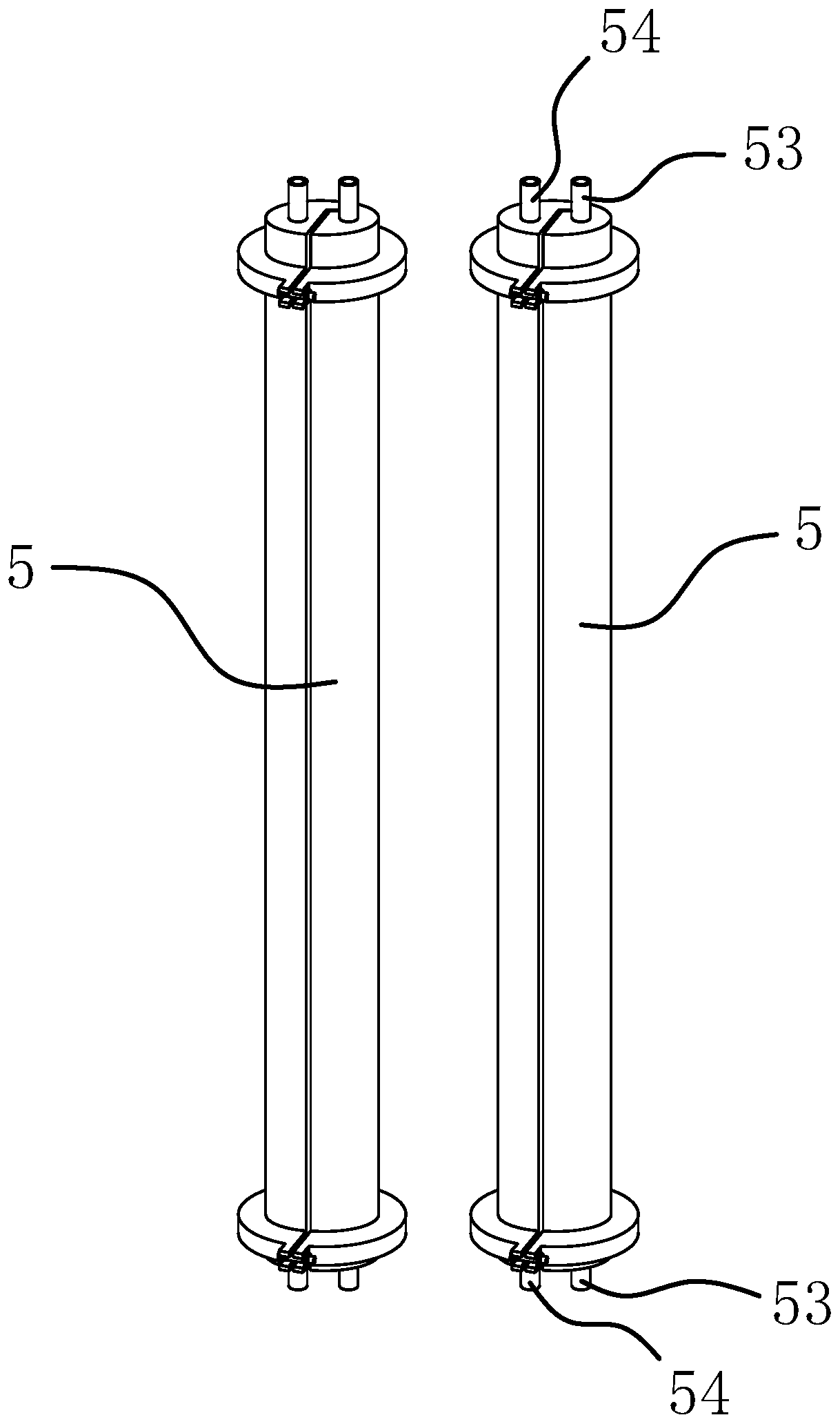

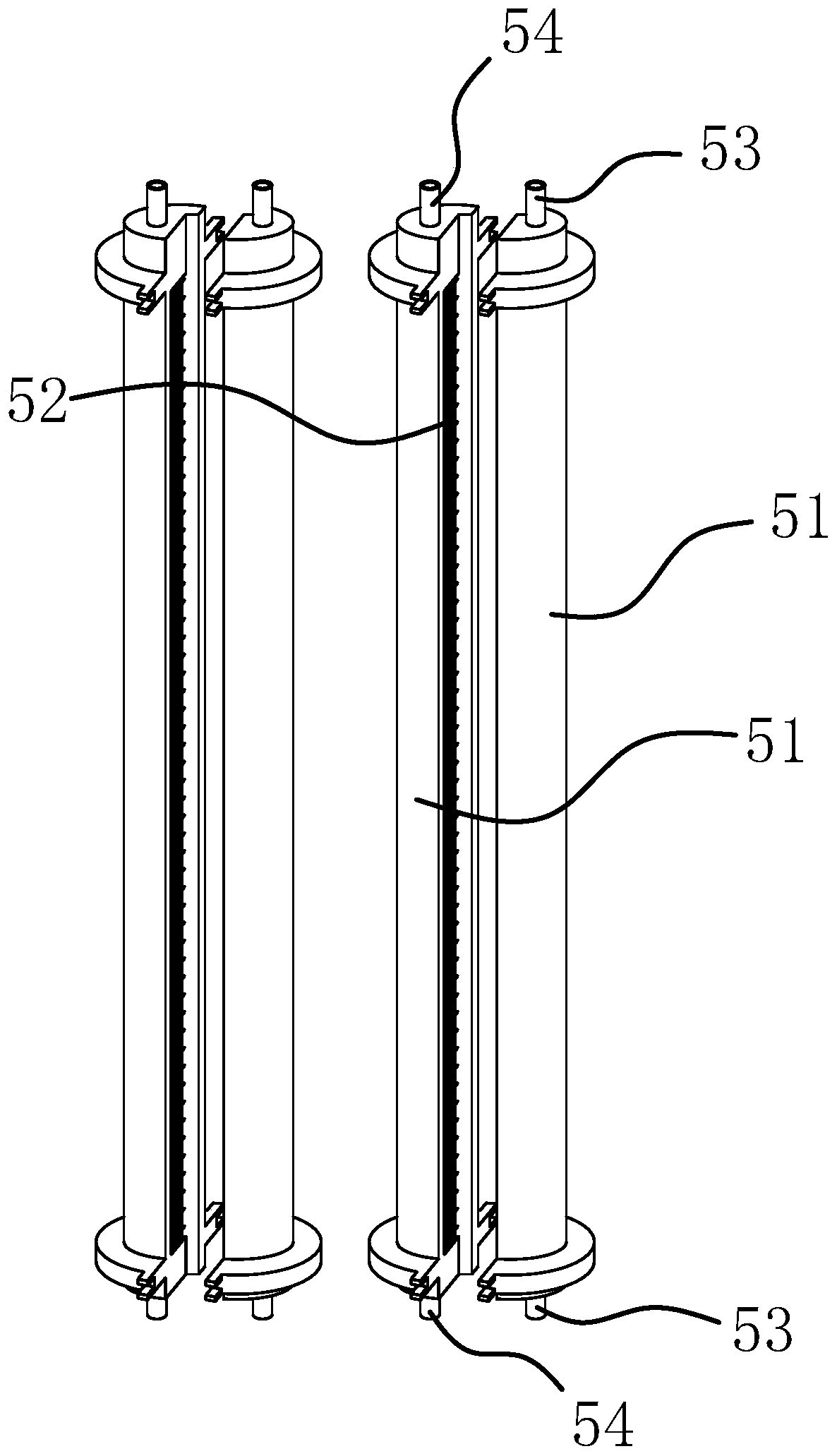

[0051] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the pulp edge device includes a base 1, a pulp box 2, a water pump 3, an air pump 4 and two clamping structures, the clamping structure is detachably connected to the base 1, and the clamping structure includes two detachably connected splints 51 The clamping plate 51 includes a curved cloth rolling surface and a flat cloth pressing surface 52. The straight surfaces of the two clamping plates 51 are overlapped to form a cylindrical cloth rolling roller 5. There is a hole in the clamping plate 51 that runs through the pressing surface 52. The two ends of the splint 51 have a liquid pipe 53 and an air pipe 54 communicating with the cavity respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com