Functional graphene and preparation method as well as application thereof to graphene /non-polar polymer composite material

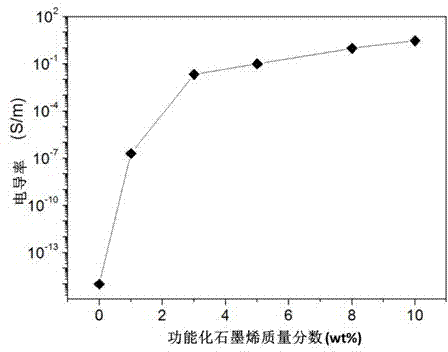

A graphene and fossil technology, applied in chemical instruments and methods, dyed organic silicon compound treatment, dyed low-molecular organic compound treatment, etc., can solve problems such as harsh reaction conditions, dispersion, and destruction of graphene conjugated structures, and achieve improved The effect of conductive performance, strong controllability and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

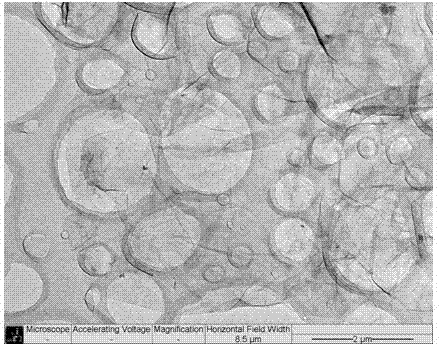

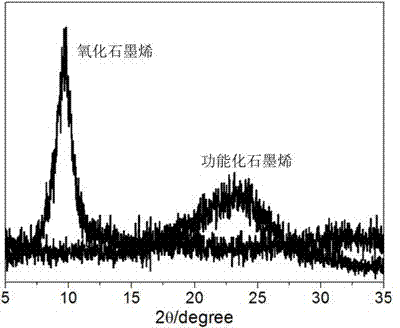

[0025] 1) The raw material graphene oxide and octyltriethoxysilane are dissolved in ethanol, and in the presence of the catalyst triethylamine, the precursor - octyltriethoxysilane modified graphene oxide is formed by condensation reaction, and the reaction temperature 40 oC , wherein the concentration of graphene oxide is 2 mg / ml, and the mass ratio of octyltriethoxysilane to graphene oxide is 3:1; the graphene oxide in this step is obtained by oxidizing graphite as a raw material, and the The oxidation method is common knowledge in the art and will not be repeated here.

[0026] 2) The octyltriethoxysilane-modified graphene oxide was ultrasonically dispersed in oleic acid solvent at 150 oC The oleic acid-functionalized graphene was obtained by reacting for 12 h. During the reaction, the graphene oxide and the modified oleic acid molecules were simultaneously reduced, and the concentration of the octyltriethoxysilane-modified graphene oxide was 2 mg / ml. After the reaction...

Embodiment 2

[0033] 1) The raw material graphene oxide and octyltriethoxysilane are dissolved in N,N-dimethylformamide, and in the presence of the catalyst triethylamine, the precursor - octyltriethoxy is formed by condensation reaction Silane-modified graphene oxide, reaction temperature 50 oC , wherein the concentration of graphene oxide is 3 mg / ml, and the mass ratio of octyltriethoxysilane to graphene oxide is 3:1;

[0034] 2) The octyltriethoxysilane-modified graphene oxide was ultrasonically dispersed in oleic acid solvent at 160 oC The oleic acid-functionalized graphene was obtained by reacting for 15 h. During the reaction, the graphene oxide was simultaneously reduced and the oleic acid molecule was connected. The concentration of the graphene oxide modified by octyltriethoxysilane was 3 mg / ml.

[0035]

Embodiment 3

[0037] 1) The raw material graphene oxide and octyltriethoxysilane are dissolved in a mixed solvent of N,N-dimethylacetamide and 1-methyl-2-pyrrolidone. Carbohydrate-Octyltriethoxysilane-modified graphene oxide, reaction temperature 50 oC , wherein the concentration of graphene oxide is 3 mg / ml, and the mass ratio of octyltriethoxysilane to graphene oxide is 3:1;

[0038] 2) Ultrasonic dispersion of octyltriethoxysilane-modified graphene oxide in oleic acid solvent at 170 oC The oleic acid-functionalized graphene was obtained by reacting for 20 h. During the reaction, the graphene oxide was simultaneously reduced and the oleic acid molecule was connected. The concentration of the graphene oxide modified by octyltriethoxysilane was 3 mg / ml.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com