Nano-calcium highly-filled polypropylene anti-aging building formwork and technology thereof

A technology of building formwork and nano-calcium, which is applied in the field of composite materials, can solve the problems of limited use of wooden formwork, consume large trees, and frequent replacement, and achieve the effect of light weight, low cost, and easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

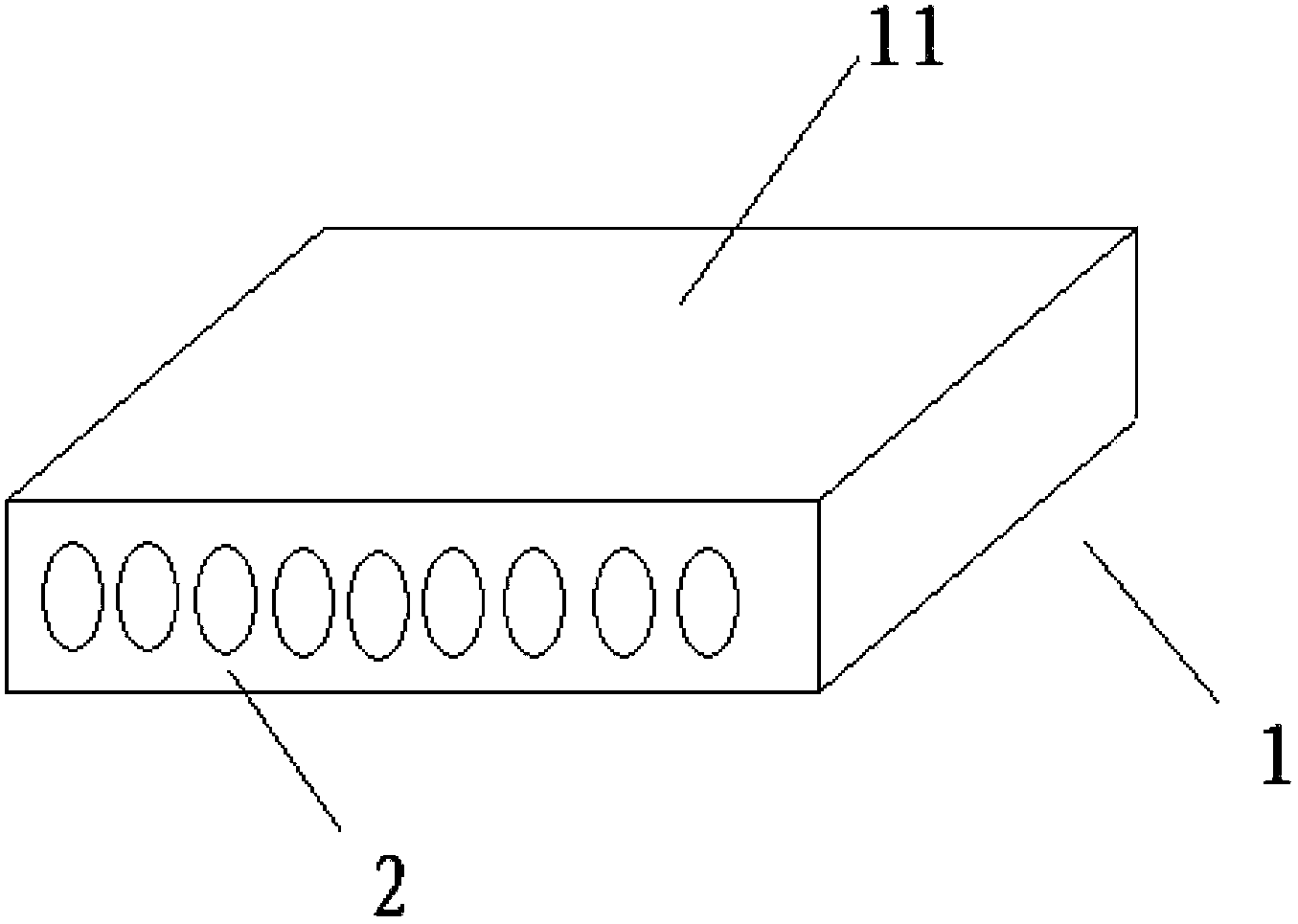

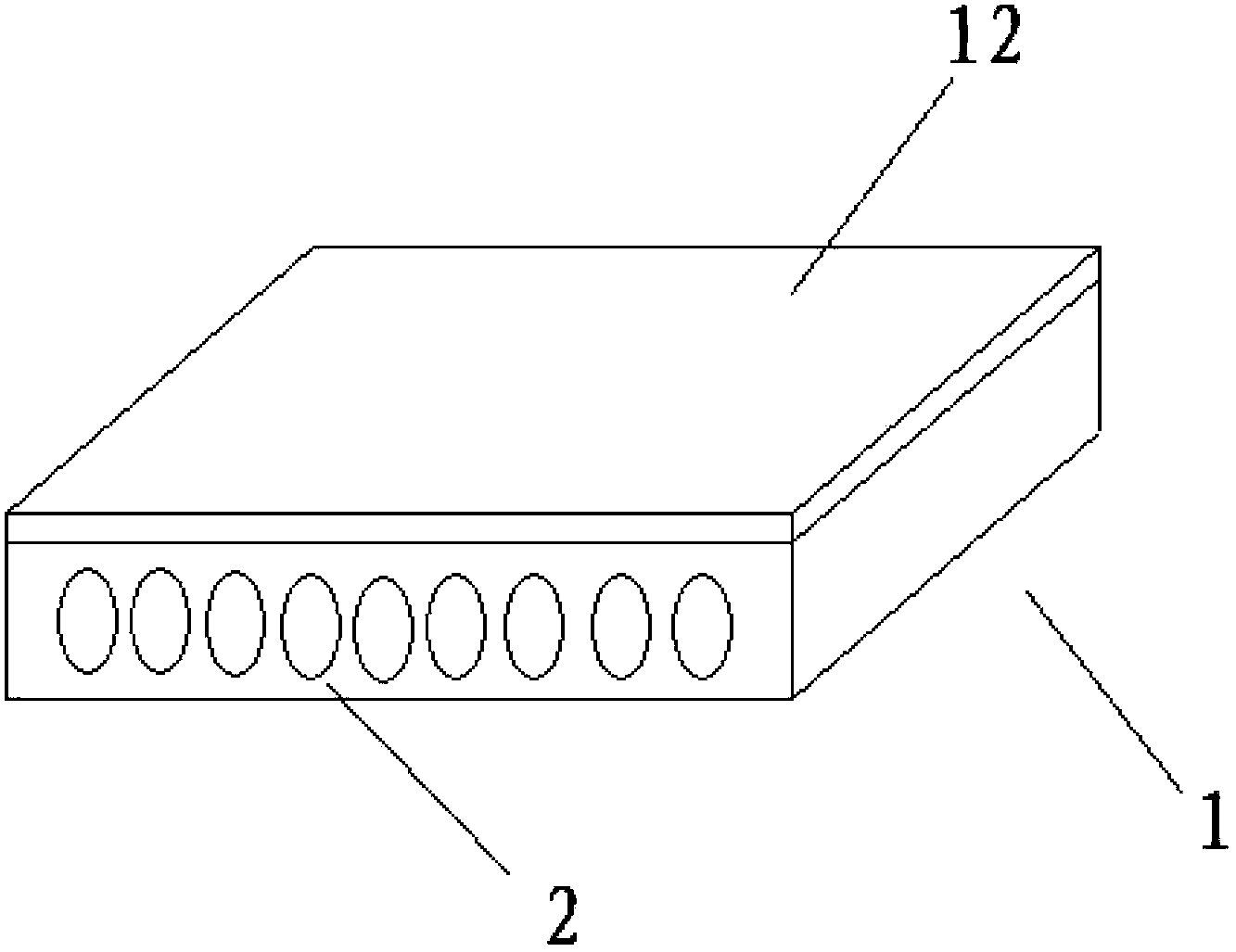

[0031] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings.

[0032] Reference figure 1 , Nano-calcium high-filled polypropylene building template, including a building template main body 1, the material of the building template main body 1 uses nano-calcium high-filled polypropylene composite material. Nano calcium high-filled polypropylene composite material is polypropylene plastic, polyethylene matrix, 800 mesh ~ 2500 mesh nano-scale calcium carbonate (heavy), coupling agent, toughening agent, ultraviolet absorber; the mass proportion is: polypropylene plastic 40-50 parts, polyethylene matrix 5-10 parts, 800 mesh-2500 mesh nano-scale calcium carbonate (weight) 20-50 parts, coupling agent 0.5-1 part, toughening agent 3-5 parts, ultraviolet absorber 3 ~5 servings.

[0033] The building template adopting the above tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com