Low-VOC (Volatile Organic Compound) polypropylene composite material for automotive interior parts and preparation method thereof

A composite material, polypropylene technology, applied in the field of polymers, can solve the problems of harming the health of drivers and passengers in the car, affecting the air quality in the car, and poor dimensional stability. The effect of improved appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

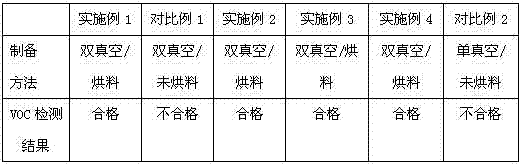

Examples

Embodiment 1

[0034] The low-VOC polypropylene composite material in this example is composed of the following raw materials by weight:

[0035] Copolymerized polypropylene 78.1 parts

[0036] Homopolypropylene 15 parts

[0037] High-density polyethylene resin (HDPE) 5 parts

[0038] Antioxidant 1076 0.3 parts

[0039] Antioxidant 168 0.2 parts

[0040] Activated carbon 1.0 parts

[0041] Ethylene bis stearamide 0.5 parts

[0042] CYASORB UV-3808 PP5 0.3 parts

[0043] Concrete preparation method comprises the following steps:

[0044] (1) Add the above-mentioned measured raw materials into the high-speed mixer and mix for 5 minutes;

[0045] (2) Put the mixed materials into a double-vacuum parallel twin-screw extruder for melting, extruding and granulating to obtain a modified polypropylene composite material; wherein the barrel temperature of the extruder is 220°C, and the screw speed is 450r / min, the melt pressure is 2.0MPa, and the vacuum degree is 0.05MPa.

[0046] (3) Pass t...

Embodiment 2

[0051] The low-VOC polypropylene composite material in this example is composed of the following raw materials by weight:

[0052] Copolymerized polypropylene 49.6 parts

[0053] High-density polyethylene resin (HDPE) 8.0 parts

[0054] Ethylene-octene copolymer 15 parts

[0055] Talc powder 15 parts

[0056] Antioxidant 168 0.2 parts

[0057] Porous silica 2.0 parts

[0058] Calcium stearate 0.8 parts

[0059] CYASORB UV-3808 PP5 0.2 parts

[0060] Concrete preparation method comprises the following steps:

[0061] (1) Add the above-mentioned measured raw materials into the high-speed mixer and mix for 8 minutes;

[0062] (2) Put the mixed material into a twin-vacuum parallel twin-screw extruder for melting, extruding and granulating to obtain a modified polypropylene composite material; wherein the barrel temperature of the extruder is 180°C, and the screw speed is 400r / min, melt pressure is 1.5MPa, vacuum is 0.01MPa

[0063] (3) The extruded and granulated particl...

Embodiment 3

[0066] The low-VOC polypropylene composite material in this example is composed of the following raw materials by weight:

[0067] Copolymerized polypropylene 40 parts

[0068] Copolymerized polypropylene 20 parts

[0069] High-density polyethylene resin (HDPE) 7 parts

[0070]EPDM rubber / propylene-alpha olefin copolymer 10 parts

[0071] Wollastonite 10 parts

[0072] mica 10 parts

[0073] Antioxidant 1076 0.3 parts

[0074] Antioxidant 168 0.2 parts

[0075] Porous molecular sieve 3.0 parts

[0076] Polyethylene wax 0.5 parts

[0077] CYASORB UV-V680 0.4 parts

[0078] Concrete preparation method comprises the following steps:

[0079] (1) Add the above-mentioned measured raw materials into the high-speed mixer and mix for 2 minutes at high speed;

[0080] (2) Put the mixed material into a twin-vacuum parallel twin-screw extruder for melting, extrusion and granulation to obtain a modified polypropylene composite material; wherein the temperature of the barrel of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com