Polyethylene composite material jointly modified by graphene, carbon nanotubes and fullerene and preparation method of polyethylene composite material

A carbon nanotube and composite material technology, applied in the field of polymer material preparation, can solve problems such as fire, loss, danger, etc., and achieve the effects of promoting composite action, simple processing technology, and stable three-dimensional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

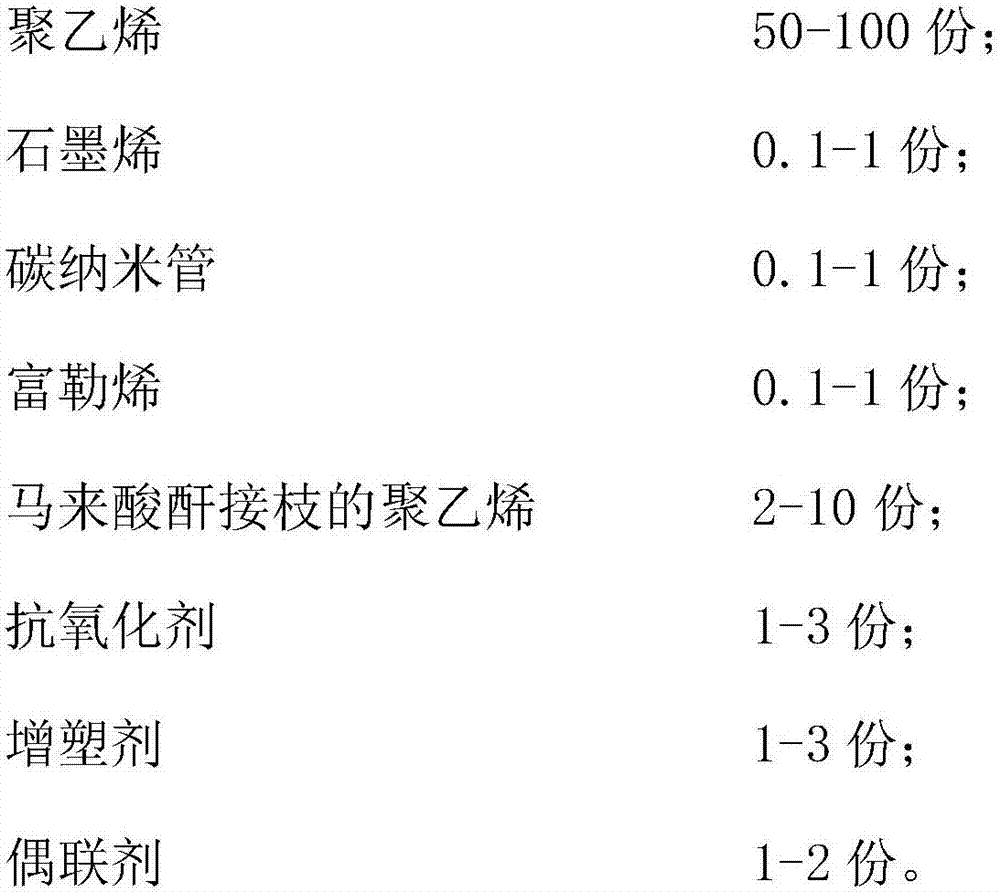

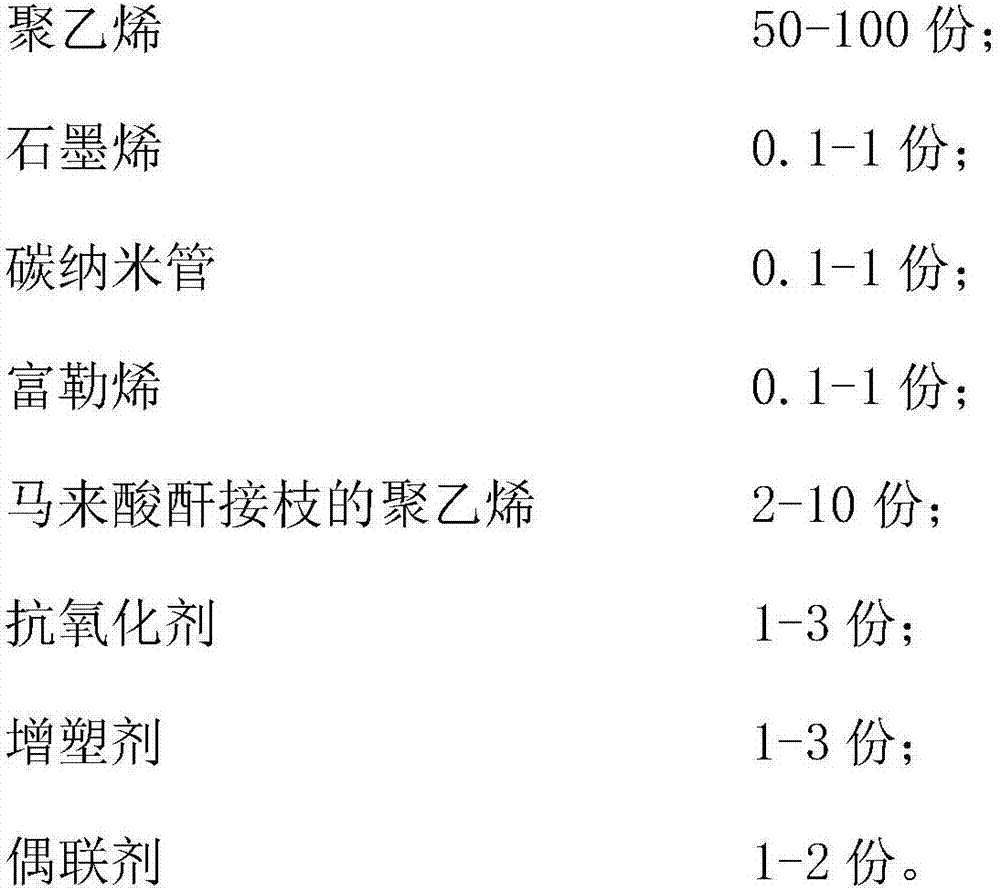

Method used

Image

Examples

Embodiment 1

[0022] Get 0.1 parts by mass of graphene, 0.1 parts by mass of multi-walled carbon nanotubes, and 0.1 parts by mass of fullerenes with a C60 structure, mix the three carbon materials uniformly by high-speed dispersion and stirring, add 50 parts by mass of polypropylene, and again Mix evenly, and finally add 2 parts by mass of maleic anhydride grafted polyethylene, 1 part by mass of monophenol antioxidant, 1 part by mass of methyl phthalate, and 1 part by mass of KH550 coupling agent. Among them, the thickness of graphene is 1 layer, the sheet diameter is 5μm, and the specific surface area is 600m 2 / g, the diameter of multi-walled carbon nanotubes is 6 nm, and the length is 10 μm. Next, the mixture was dried at 120° C. for 5 hours, fed into a twin-screw extruder for extrusion, and pelletized with a pelletizer. The temperature of each zone of the screw is: 150 °C in the first area, 160 °C in the second area, 170 °C in the third area, 170 °C in the fourth area, 160 °C in the fi...

Embodiment 2

[0024] Get 0.1 parts by mass of graphene, 0.1 parts by mass of multi-walled carbon nanotubes, and 0.1 parts by mass of fullerenes with a C60 structure, mix the three carbon materials uniformly by high-speed dispersion and stirring, add 100 parts by mass of polypropylene, and again Mix evenly, and finally add 4 parts by mass of maleic anhydride grafted polyethylene, 1 part by mass of bisphenol antioxidant, 1 part by mass of butyl phthalate, and 1 part by mass of KH560 coupling agent. Among them, the thickness of graphene is 2 layers, the sheet diameter is 10μm, and the specific surface area is 600m 2 / g, the diameter of multi-walled carbon nanotubes is 7 nm, and the length is 20 μm. Next, the mixture was dried at 120° C. for 5 hours, fed into a twin-screw extruder for extrusion, and pelletized with a pelletizer. The temperature of each zone of the screw is: 150 °C in the first area, 160 °C in the second area, 170 °C in the third area, 170 °C in the fourth area, 160 °C in the f...

Embodiment 3

[0026] Get 0.2 parts by mass of graphene, 0.2 parts by mass of multi-walled carbon nanotubes, and 0.2 parts by mass of fullerenes of C60 structure, mix the three carbon materials uniformly by high-speed dispersion and stirring, add 100 parts by mass of polypropylene, and again Mix evenly, and finally add 4 parts by mass of maleic anhydride grafted polyethylene, 1 part by mass of triphenol antioxidant, 1 part by mass of octyl phthalate, and 1 part by mass of KH570 coupling agent. Among them, the thickness of graphene is 3 layers, the sheet diameter is 15μm, and the specific surface area is 600m 2 / g, the diameter of multi-walled carbon nanotubes is 8nm, and the length is 30μm. Next, the mixture was dried at 120° C. for 5 hours, fed into a twin-screw extruder for extrusion, and pelletized with a pelletizer. The temperature of each zone of the screw is: 150 °C in the first area, 160 °C in the second area, 170 °C in the third area, 170 °C in the fourth area, 160 °C in the fifth a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com