Continuous fiber reinforced polyethylene prepreg tape, preparing method therefor and application thereof

A technology of polyethylene and prepreg tape, applied in the field of material science, to achieve the effect of solving poor bonding and excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

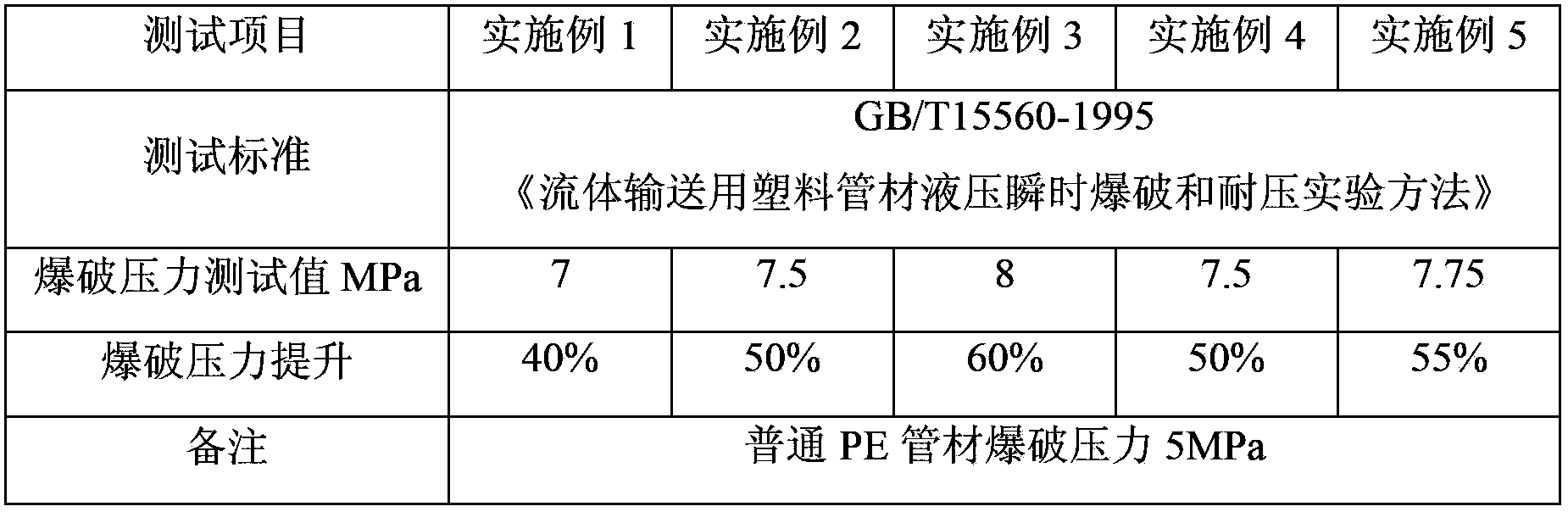

Examples

Embodiment 1

[0027] A continuous glass fiber reinforced polyethylene prepreg tape, made by the following method:

[0028] (1) 100 parts of low-density polyethylene resin matrix; 5 parts of toughening agent POE; 3 parts of compatibilizer (polyethylene grafted maleic acid); antioxidant (tetra[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester): 0.4 parts; three [2.4-di-tert-butylphenyl] phosphite: 0.2 parts) a total of 0.6 parts; alkali-resistant glass fiber 40 parts;

[0029] (2) Adopt the feeding sequence of linear low-density polyethylene resin, compatibilizer, toughener, and antioxidant, and add low-density polyethylene, polyethylene grafted maleic acid, POE, and anti-oxidant in the high-speed mixer in sequence. Oxygen, mix evenly and then seal, the mixing speed is 400r / min, and the mixing time is 60s;

[0030] (3) Add the low-density polyethylene material mixed in step (2) to the hopper of the single-screw extruder, ready to be extruded and coated. The contin...

Embodiment 2

[0032] A continuous glass fiber reinforced polyethylene prepreg tape, made by the following method:

[0033] (1) 100 parts of linear low-density polyethylene resin matrix; 6 parts of toughening agent POE grafted maleic anhydride; 5 parts of compatibilizer (polyethylene grafted maleic anhydride); antioxidant (four [β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 0.4 parts; tris[2.4-di-tert-butylphenyl] phosphite: 0.2 parts) total 0.6 parts; alkali-resistant glass fiber 50 copies;

[0034] (2) Adopt the feeding order of linear low density polyethylene resin, compatibilizer, toughening agent and antioxidant, use low speed (400r / min) in the high-speed mixer to mix for 80s, and then discharge the mixed material. bag, sealed tightly;

[0035] (3) Add the linear low-density polyethylene material mixed in step (2) to the hopper of the single-screw extruder, ready to be extruded and coated. The continuous glass fiber roll is installed on the creel, and the...

Embodiment 3

[0037] A continuous glass fiber reinforced polyethylene prepreg tape, made by the following method:

[0038] (1) Weigh 100 parts of medium-density polyethylene resin matrix; 7 parts of toughening agent POE grafted maleic anhydride; 4 parts of compatibilizer (polyethylene grafted acrylic acid); antioxidant (tetra[β-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 0.6 parts; N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Acyl) hexamethylenediamine: 0.3 parts) 0.9 parts in total; 60 parts of alkali-free glass fiber;

[0039] (2) Adopt the sequence of adding medium-density polyethylene resin matrix, compatibilizer, toughening agent and antioxidant, use low-speed (500r / min) mixing in a high-speed mixer for 60s, and then discharge the mixed materials. bag, sealed tightly;

[0040] (3) Add the medium-density polyethylene material mixed in step (2) to the hopper of the single-screw extruder, ready to be extruded and coated. The continuous glass fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com