Sodium base bentonite waterproof blanket and preparation method thereof

A technology for sodium-based bentonite and waterproof blanket, applied in the field of building materials, can solve the problems of loss of characteristics of sodium-based bentonite, complex water quality environment, etc., and achieve the effects of good anti-seepage effect, simple preparation process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

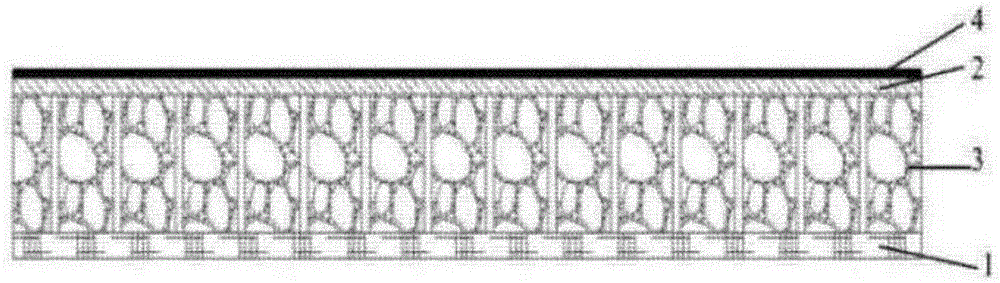

[0016] Such as figure 1 As shown, the sodium-based bentonite waterproof blanket includes: the bottom non-woven geotextile 1, the middle sodium-based bentonite layer 3 and the surface layer of plastic flat wire woven geotextile 2, and the sodium-based bentonite layer 3 is fixed by acupuncture. Between the non-woven geotextile 1 and the plastic flat wire woven geotextile 2.

[0017] The non-woven geotextile includes a fiber net, a glass fiber layer, and a polypropylene non-woven fabric layer stacked up and down in sequence, and the fiber on the fiber net is punched through opening, mixing, carding, laying, and needle punching. It is made by wearing the above layers of materials, hot air shaping and winding of finished products. The temperature of hot air shaping is controlled to be 15-25°C lower than the melting point of the fibers. The lower surface of the non-woven geotextile is provided with a layer of HDPE film with a density of 0.95- 0.96kg / l, the lower surface of the HDPE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com