Build-up welding repair process of disc shear blade and repaired disc shear blade thereby

A technology of scissor blades and disc shears, which is applied in the direction of knives, shearing devices, and shearing equipment used in shearing machines, and can solve the problems of high hardness and strength requirements, high cost, and high production costs. Achieve the effects of easy popularization and application, lower production costs, and simple repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The original standard diameter D is 362mm, the thickness H is 30mm disc scissors.

[0022] ① Mechanical processing to remove the worn outer edge, such as turning or wire cutting to remove the worn outer edge, so that the original diameter of 362mm disc scissors is processed into a diameter D 1 350mm disc scissor blade substrate;

[0023] ②The old disc scissors are pickled to remove surface rust;

[0024] ③Using carbon structural steel Q235-A to make the repair parts, the repair parts have an outer diameter of D 2 374mm, the inner diameter is 350mm, the thickness H is 30mm, and the inner edge has outer diameter D on both sides. 3 An annular groove of 365 mm and a depth h of 4 mm;

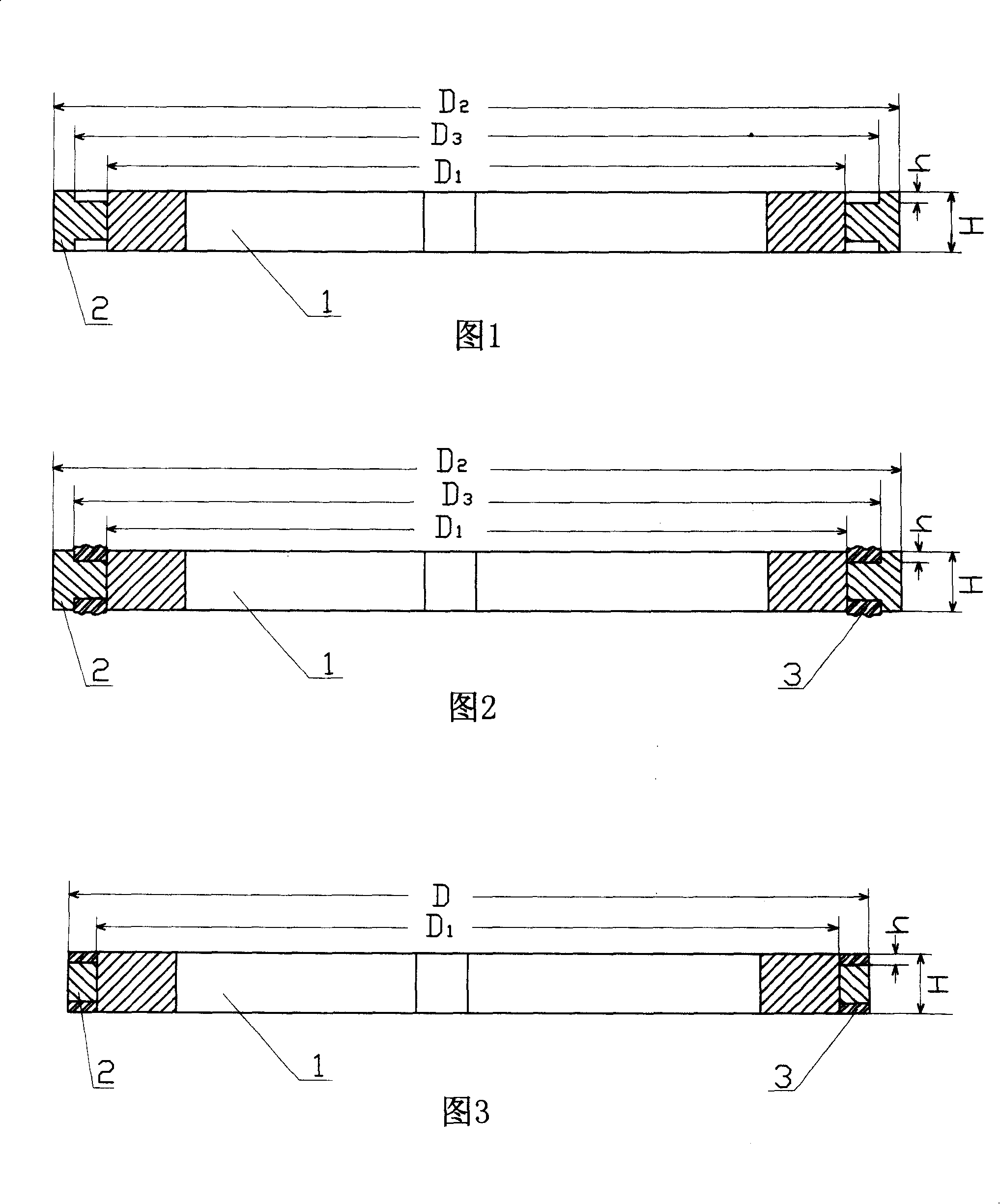

[0025] ④The repair part 2 is assembled with the disc scissor blade substrate 1; as shown in Figure 1;

[0026] ⑤ The metal surfacing electrode is preheated at 320°C for 1 hour, and the electrode used is the D327 metal surfacing electrode of Ф3.2;

[0027] ⑥Preheat the assembled disc sciss...

Embodiment 2

[0036] The original standard diameter D is 1300mm, the thickness H is 70mm disc scissors.

[0037] ①Machining to remove the worn outer edge, so that the disc scissors with the original diameter of D = 1300mm are processed into a diameter of D 1 = 1220mm disc scissors blade substrate;

[0038] ② The old disc scissors are pickled to remove surface rust and reduce welding impurities;

[0039] ③ Use No. 45 steel to make repair parts, and its outer diameter is D 2 =1330mm, inner diameter is D 1 =1220mm, thickness=70mm, both sides of the inner edge have outer diameter D 3 = 1306mm, depth h = 20mm annular groove;

[0040] ④The repair part 2 is assembled with the disc scissor blade substrate 1; as shown in Figure 1;

[0041] ⑤ The metal surfacing electrode is preheated at 400°C for 1.5 hours, and the D337 metal surfacing electrode with Ф5.0 is used;

[0042]⑥Preheat the assembled disc scissors at 400°C for 1 hour;

[0043] ⑦Use the preheated welding rod to weld the preheated as...

Embodiment 3

[0049] The original standard diameter D is 820mm, the thickness H is 50mm disc scissors.

[0050] ①Machining to remove the worn outer edge, so that the disc scissors with the original diameter of D=820mm are processed into a diameter of D 1 = 780mm disk scissors blade substrate;

[0051] ② The old disc scissors are pickled to remove surface rust and reduce welding impurities;

[0052] ③Using No. 25 steel to make repair parts, its outer diameter is D 2 =844mm, inner diameter is D 1 =780mm, thickness H=50mm, both sides of the inner edge have outer diameter D 3 =826mm, the annular groove of depth h=14mm;

[0053] ④The repair part 2 is assembled with the disc scissor blade substrate 1; as shown in Figure 1;

[0054] ⑤ The metal surfacing electrode is preheated at 380°C for 1.2 hours, and a self-made metal surfacing electrode with Ф4.0 is used. The components and ratios of W, Mo, V, Cr and other components contained in this electrode are consistent with the standard brand D337...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com