Method for drilling center holes in two end faces of cylindrical roller by using depth control device

A depth control, cylindrical roller technology, applied in feeding devices, boring/drilling, drilling/drilling equipment, etc., can solve the problem of poor coaxiality, low production efficiency, affecting the machining accuracy of cylindrical rollers, etc. problem, to achieve the effect of convenient use, easy production, improved processing accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

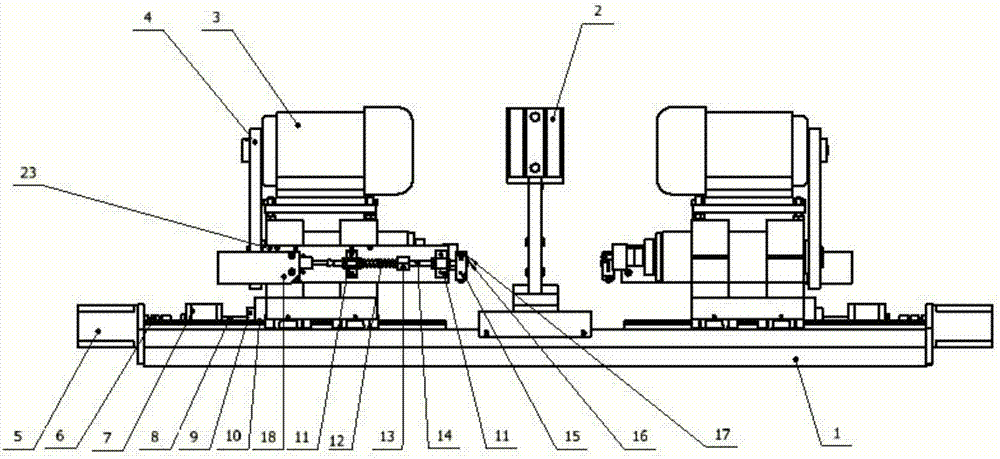

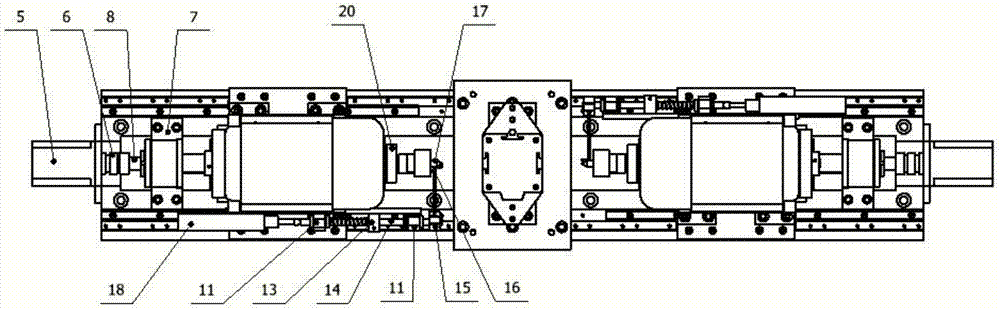

[0019] The present invention is a method for drilling the center holes on both ends of cylindrical rollers by using a depth control device. The method can not only drill the center holes on both ends of cylindrical rollers simultaneously, but also ensure the same working speed and working depth. The central holes on both ends of the cylindrical rollers have higher coaxiality, which simplifies the processing procedure and improves the processing accuracy and production efficiency.

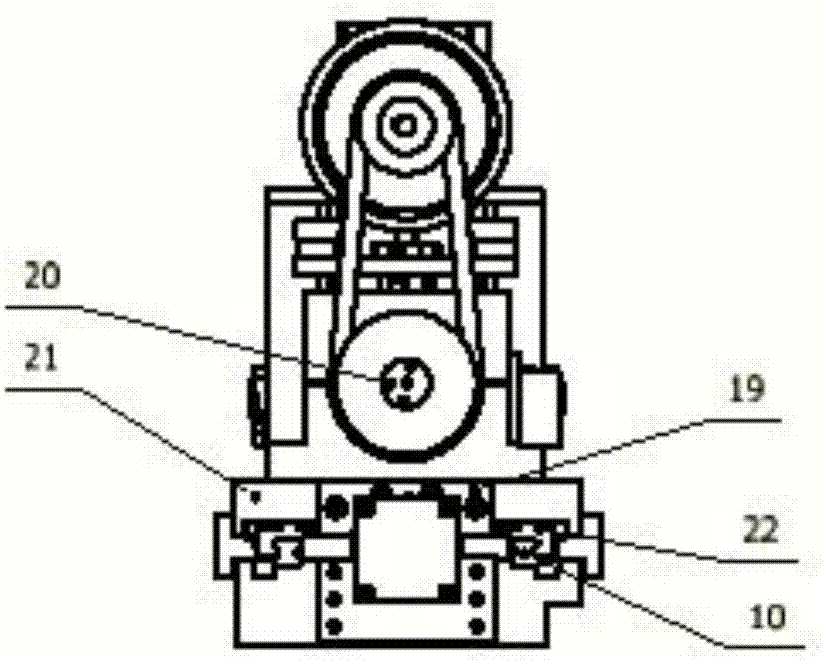

[0020] The present invention uses a depth control device and a controller, and the depth control device includes a base 1, a workpiece clamping device 2, a left punching power device, a right punching power device, a left lateral drive device, a right lateral drive device, a left measurement device and the right measuring device, the controller controls the working speed, working depth and rotation speed of the depth control device and meets the various working requirements of the depth control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com