Automobile double-drive-axle tester

A technology of double drive axle and test device, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc. Rear axle linkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

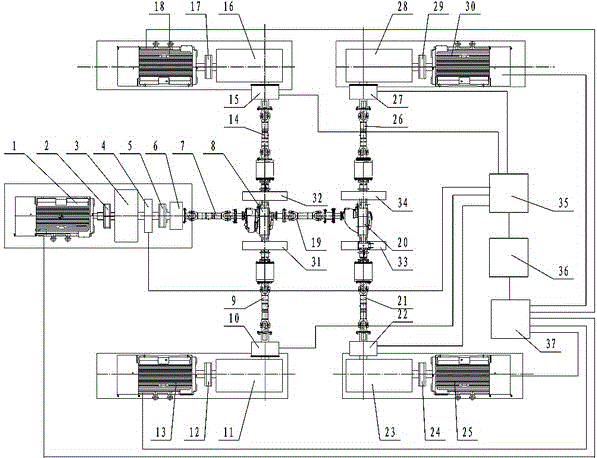

[0013] figure 1 Among them, the supporting device of the present invention includes an intermediate support (6), a first support (31), a second support (32), a third support (33), and a fourth support (34). The two ends of the middle axle (8) of the vehicle to be tested are fixed on the support one (31) and the support two (32) at the same time. The two ends of the automobile rear axle (20) to be detected are fixed on the support three (33) and the support four (34) at the same time. The test device has five motors, of which the driving motor (1) is used for power drive, 1# loading motor (13), 2# loading motor (18), 3# loading motor (25) and 4# loading motor (30) According to the requirements of the vehicle middle axle (8) to be tested and the vehicle rear axle (20) to be tested, power linkage loading is performed simultaneously.

[0014] The drive motor (1) is connected to the 1# reduction box (3) through the 0# coupling (2), and the 1# reduction box (3) passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com