Continuous machine elevation adjusting mechanism and automatic tilling depth adjusting method thereof

A technology of adjusting mechanism and elevation, which is applied in the field of agricultural tillage equipment, can solve problems such as delayed adjustment, affecting operation quality, and tractor overload and flameout, so as to reduce damage, improve the quality and efficiency of rotary tillage operations, and achieve the effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

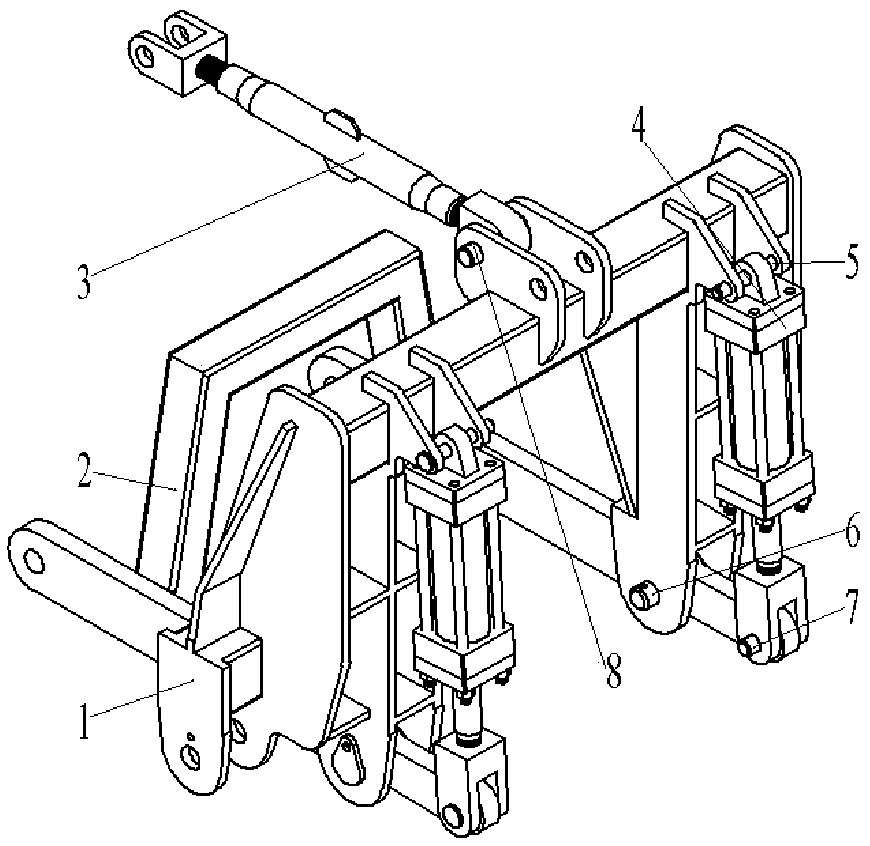

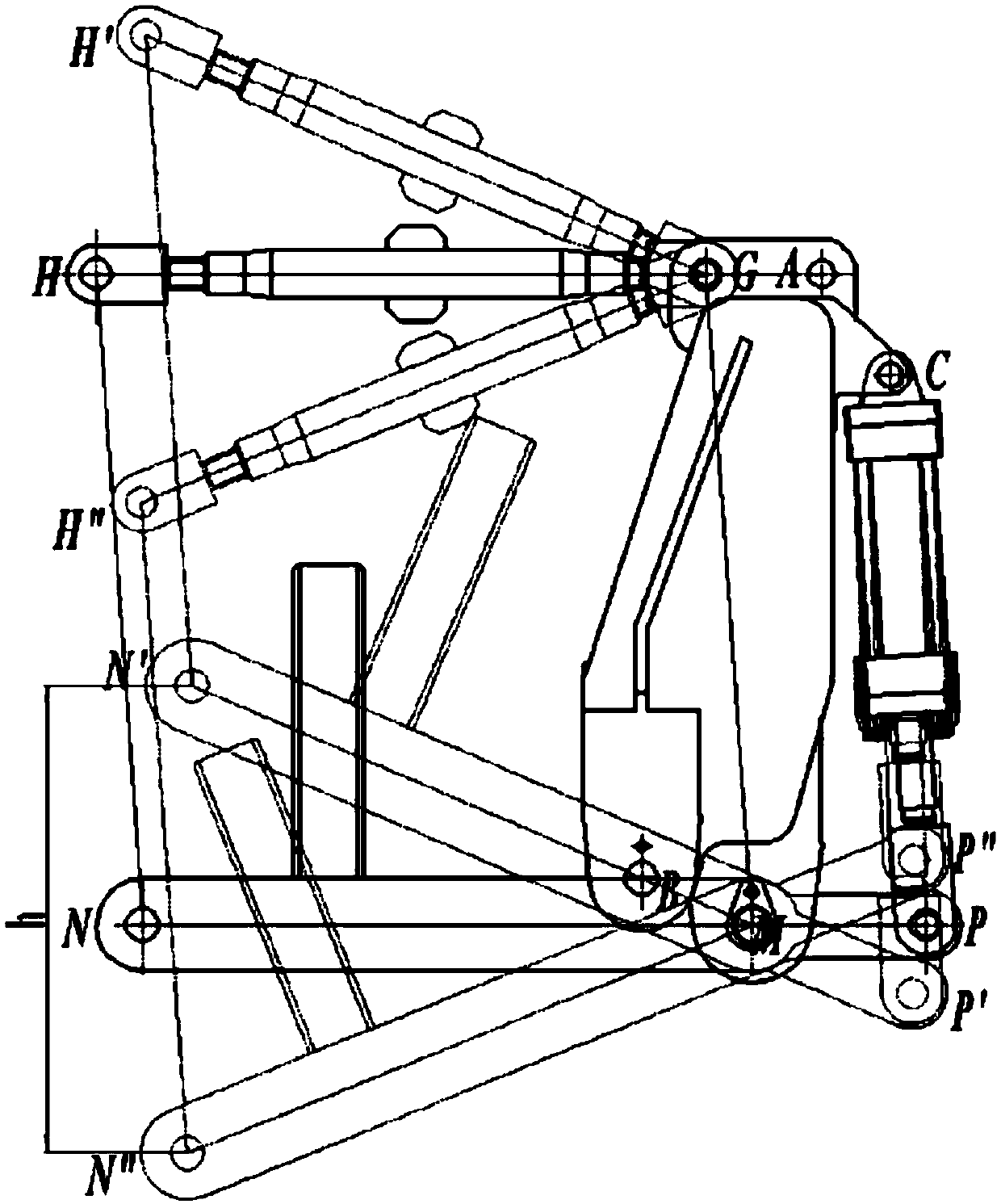

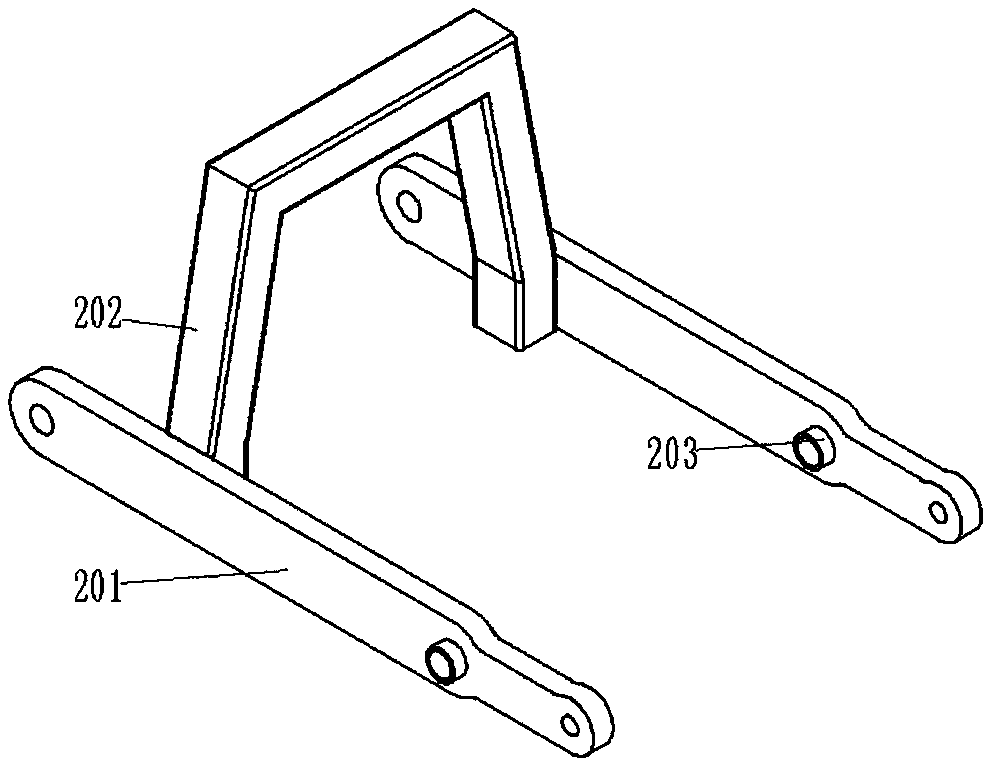

[0034]A mechanism for continuously adjusting the elevation of a machine tool mainly includes an elevation adjustment bracket, a lower lifting bracket, an upper pull rod, and two elevation oil cylinders. The height adjustment bracket includes a horizontal part extending along the left and right direction and a vertical part erecting the horizontal part. The front part of the horizontal part is provided with the upper connection point of the elevation cylinder, and the middle part of the horizontal part is provided with the upper connection point of the tractor three-point suspension mechanism. The rear part of the horizontal part is provided with the front connection point of the upper tie rod, the lower inner part of the longitudinal part is provided with the connection point of the lower lifting bracket, and the lower part of the longitudinal part is provided with the lower connection point of the tractor three-point suspension mechanism, and the elevation adjustment bracket is...

Embodiment 2

[0042] This embodiment adopts the continuous height adjustment mechanism of the implement in the first embodiment, which is installed between the three-point suspension mechanism of the tractor and the rotary cultivator. This embodiment adopts a laser control system.

[0043] Figure 5 As shown, it mainly includes a tractor, a continuous height adjustment mechanism for implements, a rotary tiller, a hydraulic valve group, a controller, a laser receiver mounting rod, and a laser transmitter.

[0044] A method for automatically adjusting the depth of tillage with a continuous height adjustment mechanism for implements. During operation, due to the unevenness of the farmland surface, the front and rear wheels of the wheeled tractor are not on the same level during field operations, resulting in the height of the rotary tiller relative to the field surface. Because the pitch of the tractor changes at any time, the laser receiver installed on the receiver mounting rod senses the l...

Embodiment 3

[0046] This embodiment adopts the continuous height adjustment mechanism of the equipment in the first embodiment, which is installed between the three-point suspension mechanism and the rotary tiller. In this embodiment, an ultrasonic ranging sensor control system is adopted.

[0047] Image 6 As shown, it mainly includes tractor, implement height continuous adjustment mechanism, rotary tiller, hydraulic valve group, controller and ultrasonic distance measuring sensor (two, one on the left and one on each side).

[0048] A method for automatically adjusting the depth of tillage of a machine tool elevation continuous adjustment mechanism. During operation, the rotary tillage depth of the rotary tiller is first set, and the average value of the distance from the ground measured by the two ultrasonic distance measuring sensors at this time is recorded. 0 , due to the uneven potholes on the farmland surface, the front and rear wheels of the wheeled tractor are not on the same le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com