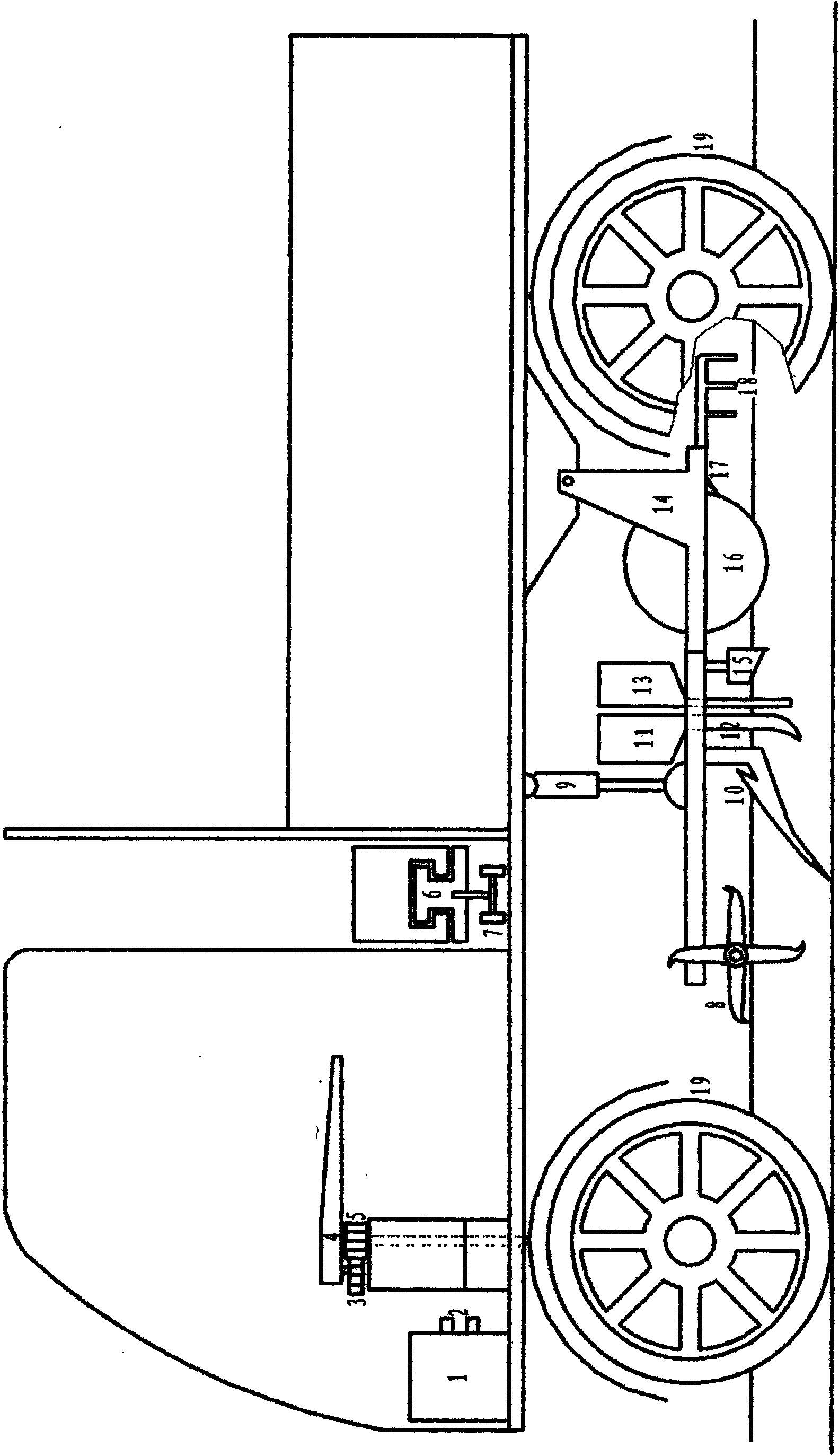

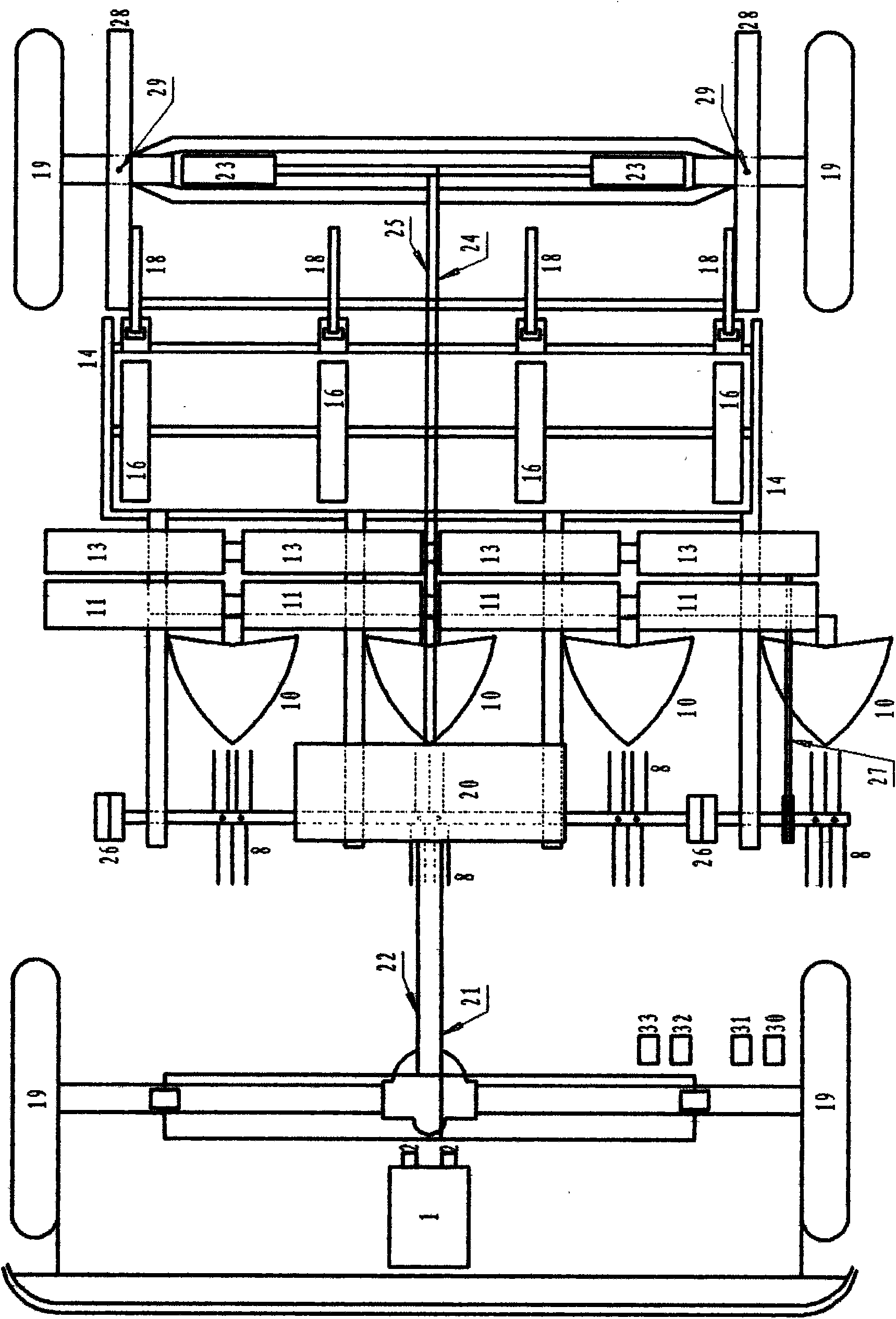

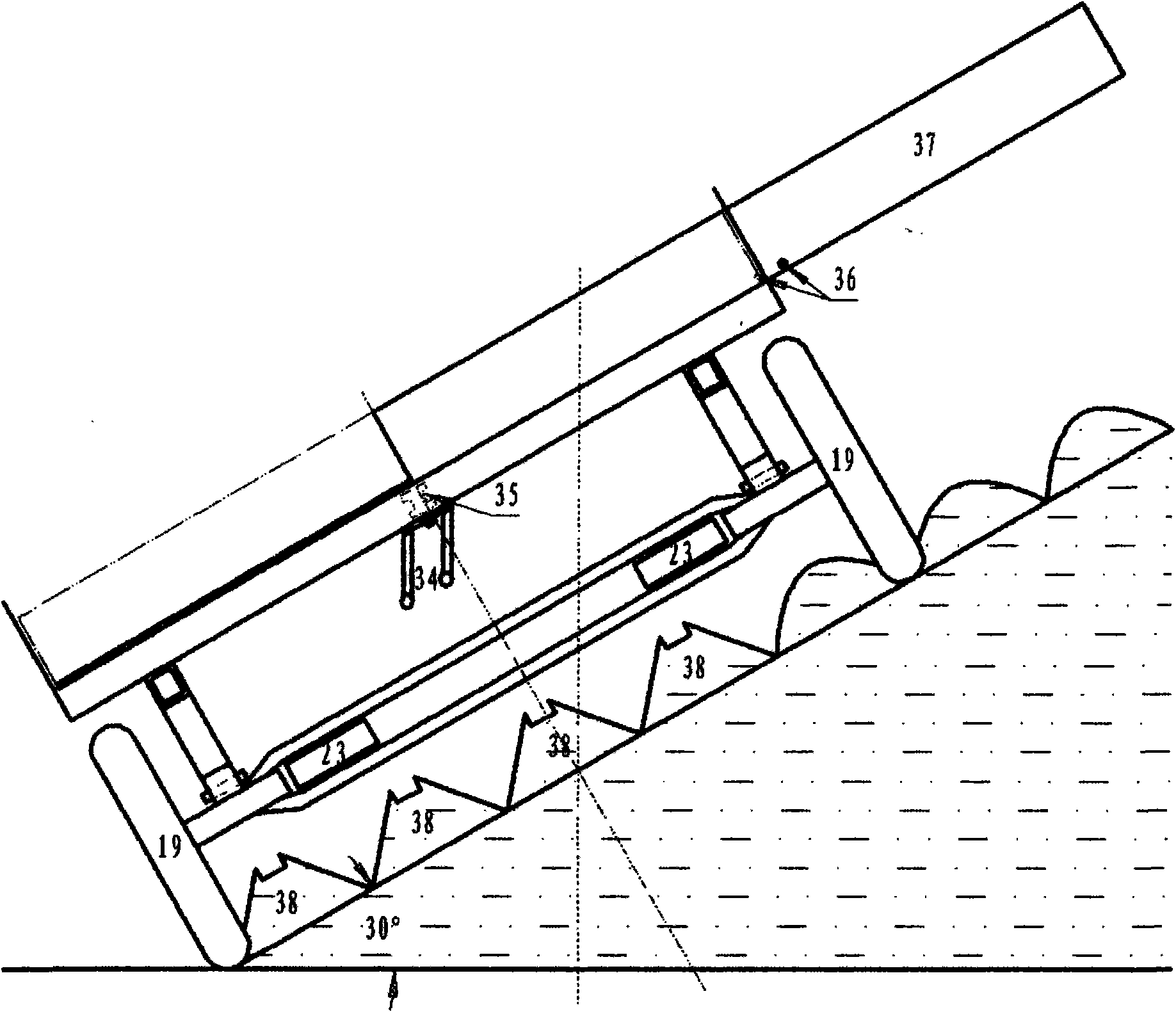

Multifunction hydraulic agricultural vehicle

A car body and wheel technology, applied in the field of E2 auto key parts and H11 agricultural machinery, can solve problems such as difficult to adapt to multiple workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It does not rely on pushing and pulling to make the wheels rotate to drive the car to walk, but only through the shaft for power transmission. In the present invention, a whole shaft is disconnected, a power source is installed at the concentric position of the two disconnected shafts, and an arch bridge with a strength greater than the original shaft is attached to the side of the shaft to make it integrated, that is, a single coupling shaft and Dual shaft. It is a single shaft that is attached to the arch bridge on one side, and a double shaft is attached to the arch bridge on both sides. At the same time, the disconnected original shaft is divided into three layers, the first layer is the shaft skin, the second layer is the shaft sleeve, and the third layer is the half shaft, one end is fixed on the power source, and the other end is fixed on the pot body. The wheels cooperate with the pot body and the bearings so that the half shaft shaft skin does not turn. Like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com