Calibration device of miniature pressure sensor

A pressure sensor and calibration device technology, which is applied in the direction of measuring devices, instruments, force/torque/power measuring instrument calibration/testing, etc., can solve the problems of small contact surface of spherical contacts, small size, and susceptibility to environmental interference, etc. Achieve the effect of strong anti-eccentric load ability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

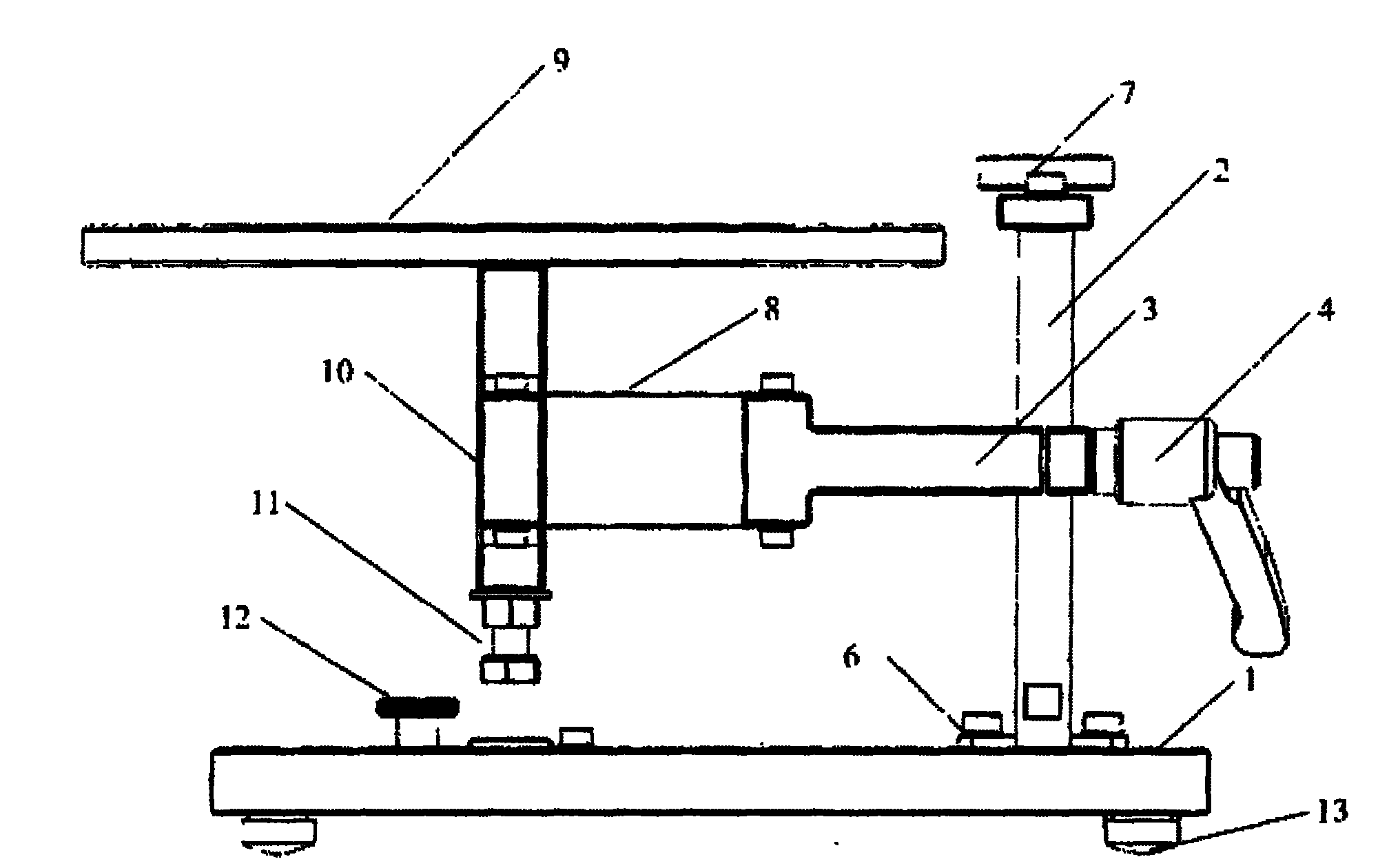

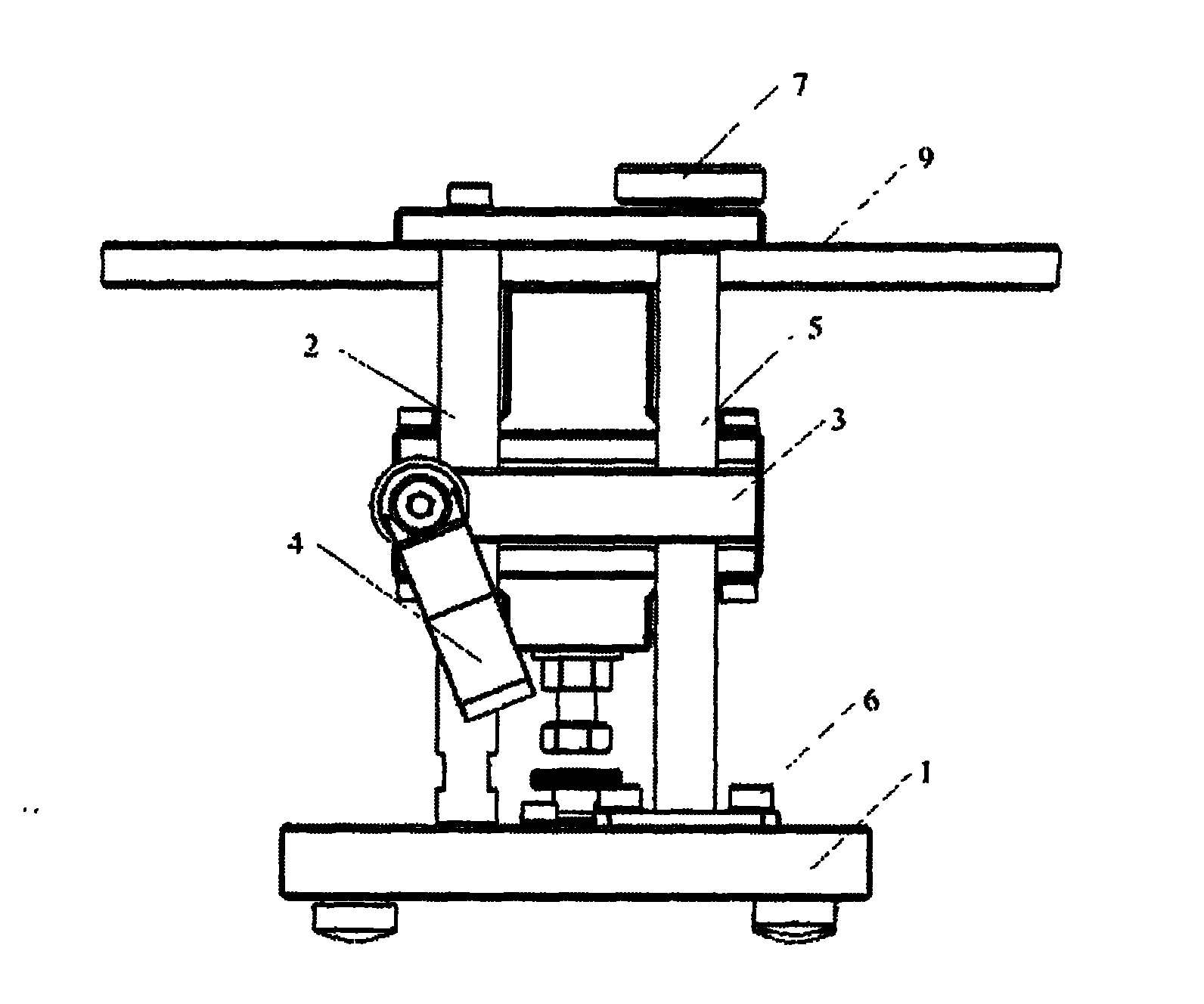

[0028] Firstly, place the calibration table base 1 of the present invention on a flat ground or a desktop, adjust the base adjustment nut 13 with a spirit level, and calibrate the horizontal plane of the calibration table base 1 to ensure that the base 9 is in a horizontal state.

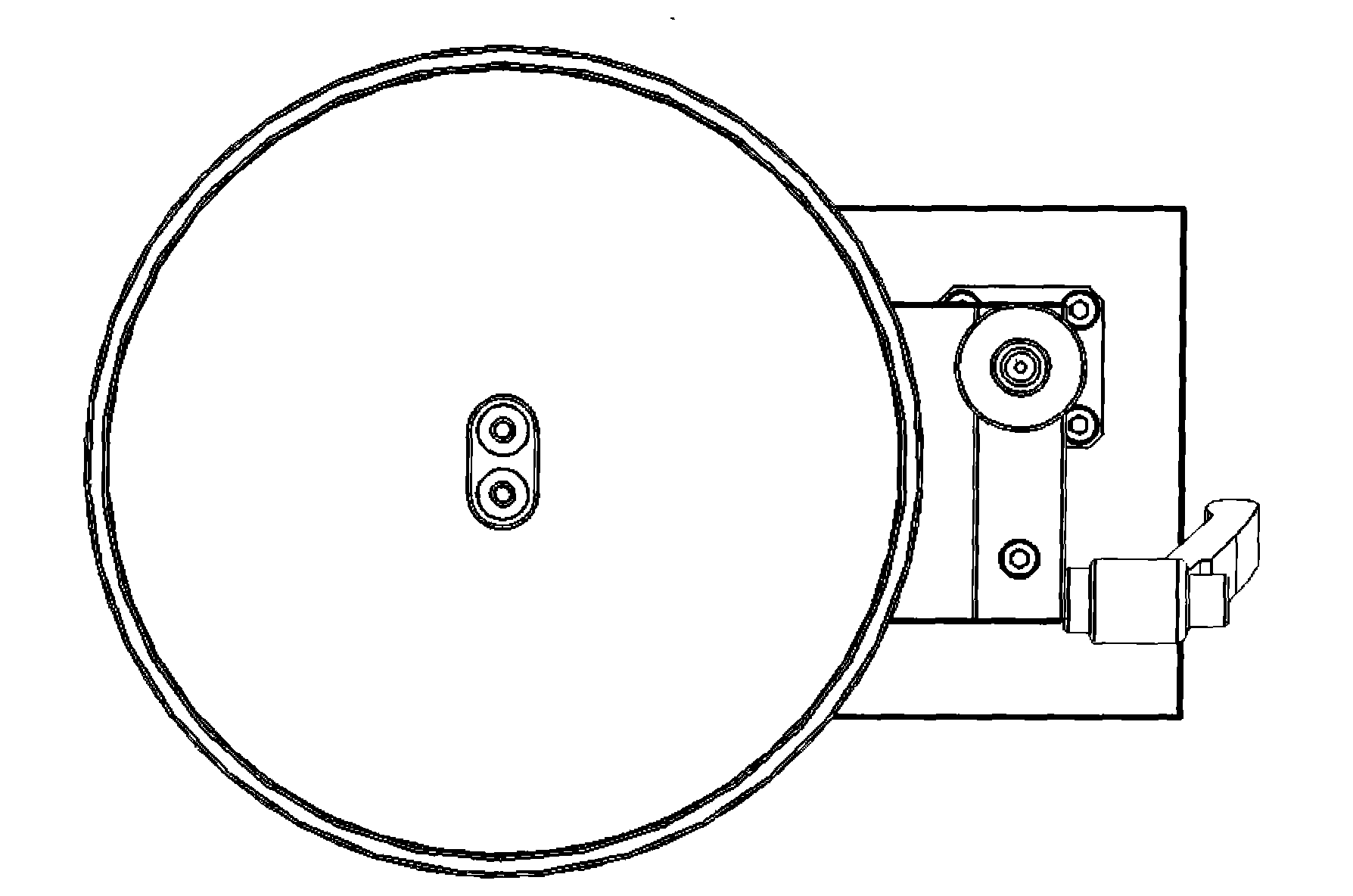

[0029] Then, install the micro pressure sensor to be calibrated on the sensor fixture 12 of the calibration table base 1, and adjust the position so that the stainless steel ball on the top of the micro sensor faces the adjustable sensor pressure head 11 above. Loosen the fixing bolt handle 4, and turn the screw knob 7 to adjust the height position of the seat 3 and the left bearing seat 10, so that the distance between the adjustable sensor pressure head 11 and the contact point of the micro sensor is about 0.5 cm, and the deflection correction spring steel sheet 8 In a naturally curved state.

[0030] Secondly, connect the sensor measurement circuit and observe the output signal value of the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com