Forging press

A forging press and hydraulic technology, which is applied in the field of forging presses, can solve problems such as difficult synchronization of double cylinders, rapid wear of machine parts, and limitation of moving speed, and achieve the effects of good lubrication, easy forging, and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

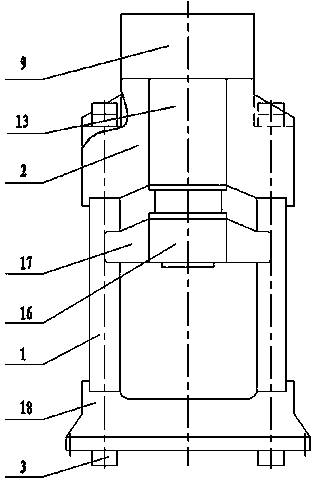

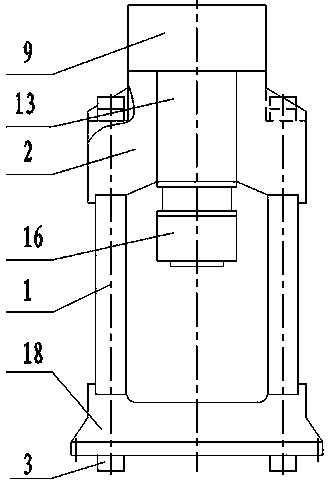

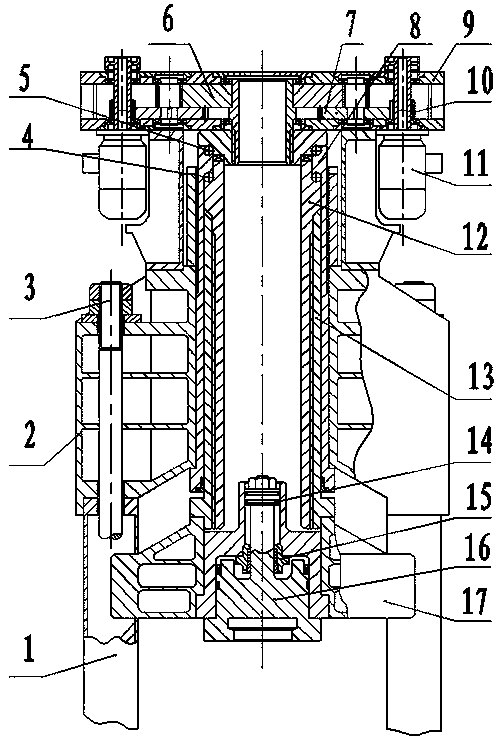

[0039] Example 1 as figure 1 with image 3 As shown, the forging press of the present invention includes an upper beam 2, a lower beam 18 and at least one column 1. Of course, a plurality of columns 1 are generally used to play a fixing role. In this embodiment, two columns 1 are used, and the column 1 The lower end of the lower beam is fixed on the lower beam 18, the upper beam 2 is arranged on the upper end of the column 1 to form a frame, and the upper beam 2, the lower beam 18 and a column 1 are fixedly connected to form a frame by prestressed bolts 3, and adopt Hydraulic tensioner is used to complete the preload. The frame preloaded by this method has very good rigidity, and even reaches the requirement of infinite rigidity. Only when this requirement is met can it withstand the shock and vibration during forging. The frame material structure can be greatly strengthened selectively, and casting parts or structural parts can be used. This kind of prestressed structure fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com