A marine weight pipe coating trolley

A counterweight pipe and coating technology, which is applied in ceramic molding machines, manufacturing tools, surface layering devices, etc., can solve the problems of imperfect marine pipeline concrete counterweight technology, no marine pipeline construction enterprises, etc., and achieve the scope of pipeline adaptation. Wide, strong anti-eccentric load ability, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

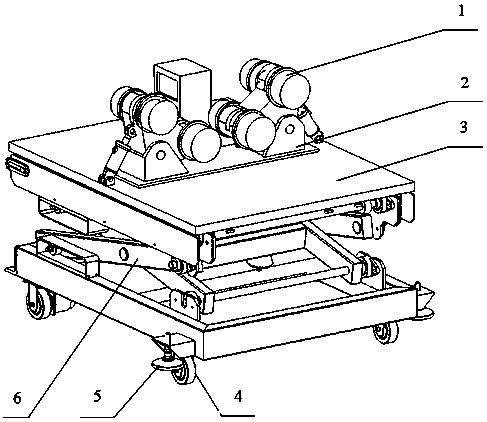

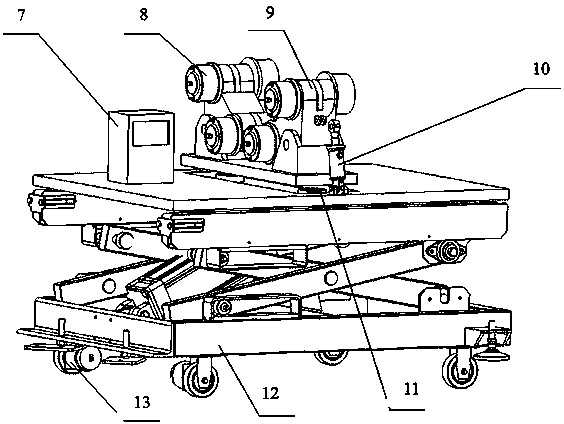

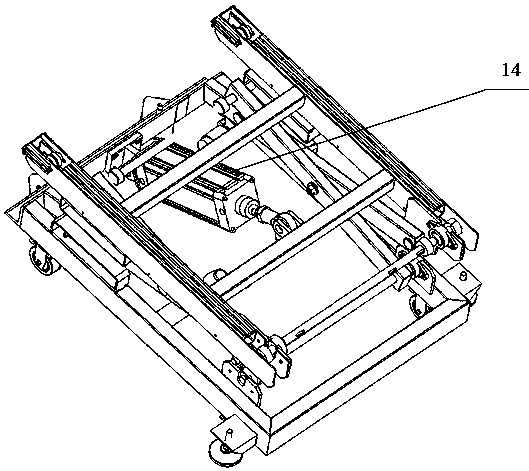

[0022] A trolley for coating marine counterweight pipes in the present invention is mainly composed of support wheels 1, base 2, lifting platform 3, wheels 4, telescopic legs 5, scissor arms 6, control cabinet 7, hydraulic motor 8, support base 9, Supporting hydraulic cylinder 10, weighing sensor 11, chassis 12, traveling hydraulic motor 13 and lifting hydraulic cylinder 14 are composed. The same coating trolley is provided with two pairs of support wheels 1 with different spacings. The support wheels 1 with large spacing can be self-adjusted according to the pipe diameter to support large diameter pipes, and the support wheels 1 with small spacing support small diameter pipes; the support wheels 1 are installed On the support base 9, the hydraulic motor 8 drives it to rotate, thereby realizing the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com