A horizontal cam servo press driven by multiple motors

A multi-motor drive, servo press technology, applied in the driving device of the forging press and other directions, can solve the problems of the long drive chain of the servo press, frequent start and stop of the motor, difficult processing and assembly, etc., and achieve strong anti-eccentric load capacity. , The effect of improving working characteristics and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

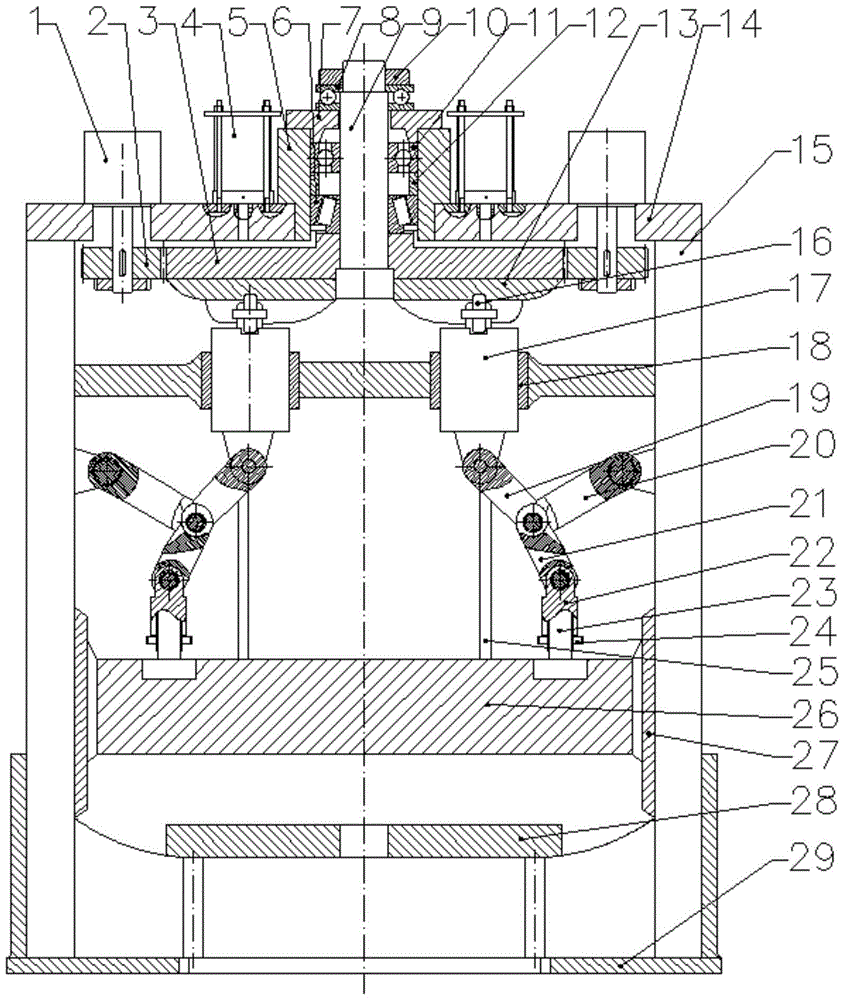

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] With reference to the accompanying drawings, a multi-motor-driven horizontally placed end face cam servo press includes an upper body 14, a column 15 and a lower body 29, the upper body 14 is connected together through the column 15 and the lower body 29, Two servo motors 1 are symmetrically installed on the upper body 14, the output shaft of the servo motor 1 is equipped with a pinion 2, the two pinions 2 cooperate with the large gear 3, the large gear 3 is connected to the shaft 9, and the shaft 9 passes through The rolling bearing 11 and the tapered roller bearing 6 are installed in the large sleeve 5, the large sleeve 5 is connected to the upper body 14, the end cover 7 is installed on the outside of the rolling bearing 11, and a small sleeve is installed between the rolling bearing 11 and the tapered roller bearing 6 The cylinder 12 and the shaft 9 are su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com