Preparation method of end-sealed prefabricated concrete enlarged head tubular pile

A technology of precast concrete and enlarged head, which is applied in the test of sheet pile walls, buildings, and foundation structures, etc., can solve the problems of not bearing the full cross-section, reducing the stability of steel plates, and not being an effective area, achieving low profile height, testing Convenient, good natural linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

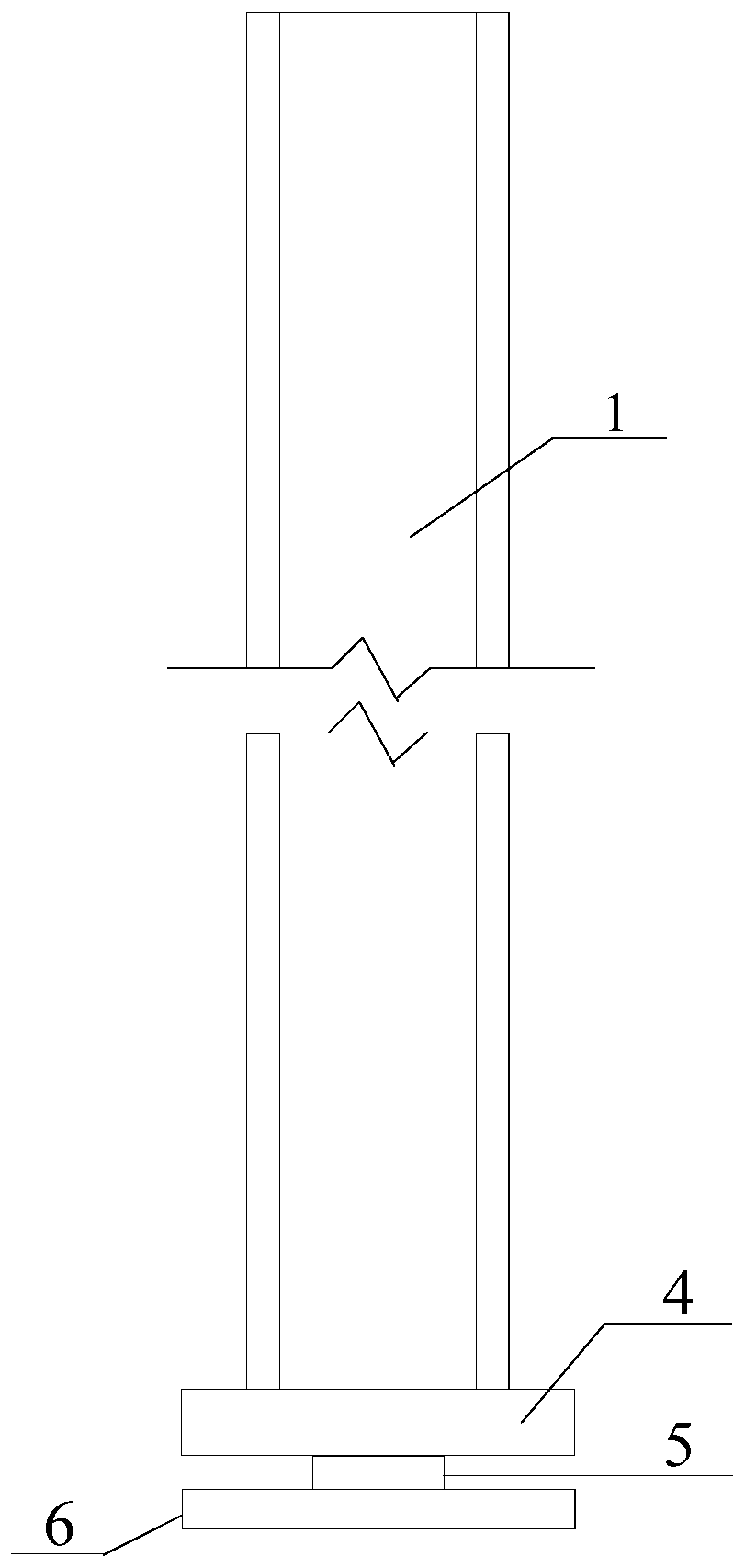

[0026] The specific process of preparing the end-sealed precast concrete enlarged head tubular pile in this embodiment is as follows:

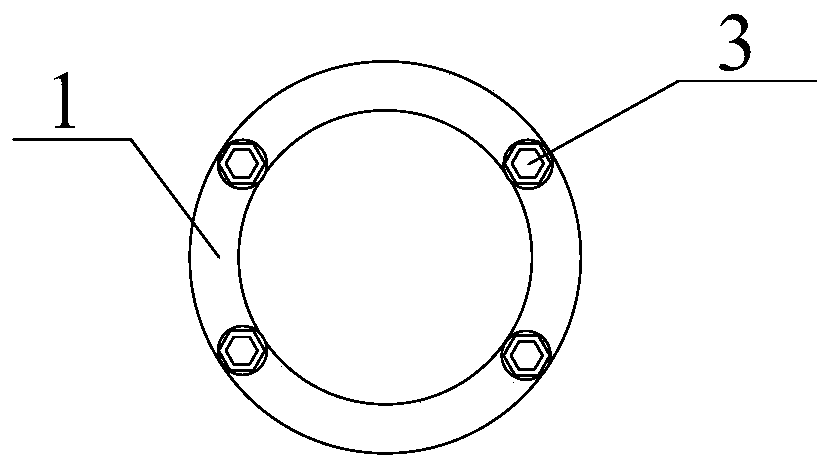

[0027] (1) Pre-embed the nut 3 on the end plate of the prefabricated concrete pipe pile 1 pile end, and glue the hole of the nut 3 with tape on the upper and lower surfaces of the nut, so as to prevent the concrete from splashing on the thread and affecting the subsequent installation;

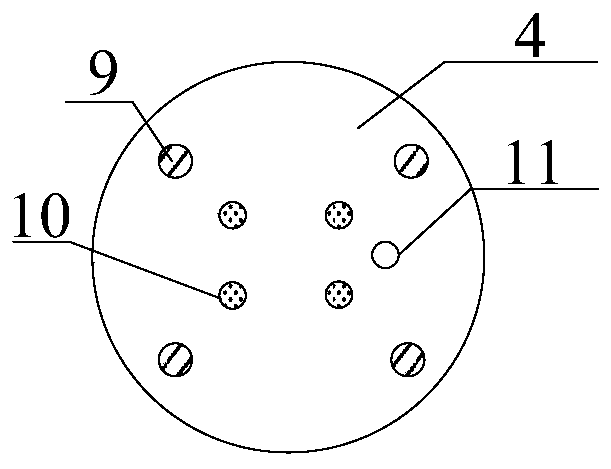

[0028] (2) In order to ensure that the expansion head 4 does not bend during the pile sinking process and the working stage, a certain thickness must be met, so the diameter of the expansion head 4 should be based on the diameter of the precast concrete pipe pile 1 and the characteristic value of the single pile bearing capacity and the expansion The thickness of the head plate is determined comprehensively, and the corresponding position is marked on the enlarged head 4 according to the pre-embedded nut 3 at the end of the precast concrete pipe pile 1, and the...

Embodiment 2

[0036] In this embodiment, the preparation of end-sealed prefabricated concrete enlarged head tubular piles and the pile end resistance test are carried out in a certain project. The project site mainly distributes muddy soil layers and cohesive soil layers. The soil layer distribution is shown in Table 1:

[0037] Table 1: Physical and mechanical property indexes of soil layer

[0038]

[0039] Where / : indicates that it is not given in the survey report;

[0040] End sealing prefabricated concrete enlarged head tubular pile (i.e. following expanded bottom pile) described in the present embodiment adopts the pile length of concrete tubular pile to be 10m, and pile diameter is 400mm, and wall thickness is 9.5mm, and the diameter of enlarged head is 500mm , the pile pressing method in this embodiment adopts the static pile pressing method, and the pile pressing force and penetration depth of the expanded bottom pile and the non-expanded bottom pile are compared, and the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com