Telescopic bidirectional loading and unloading conveyor

A conveyor and telescopic mechanism technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as poor flexibility, low work efficiency, and inability to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

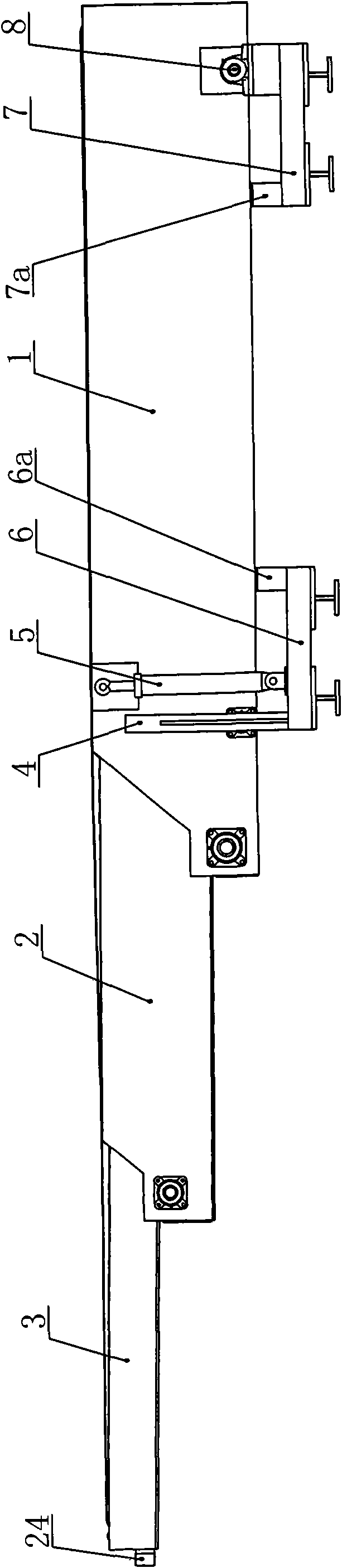

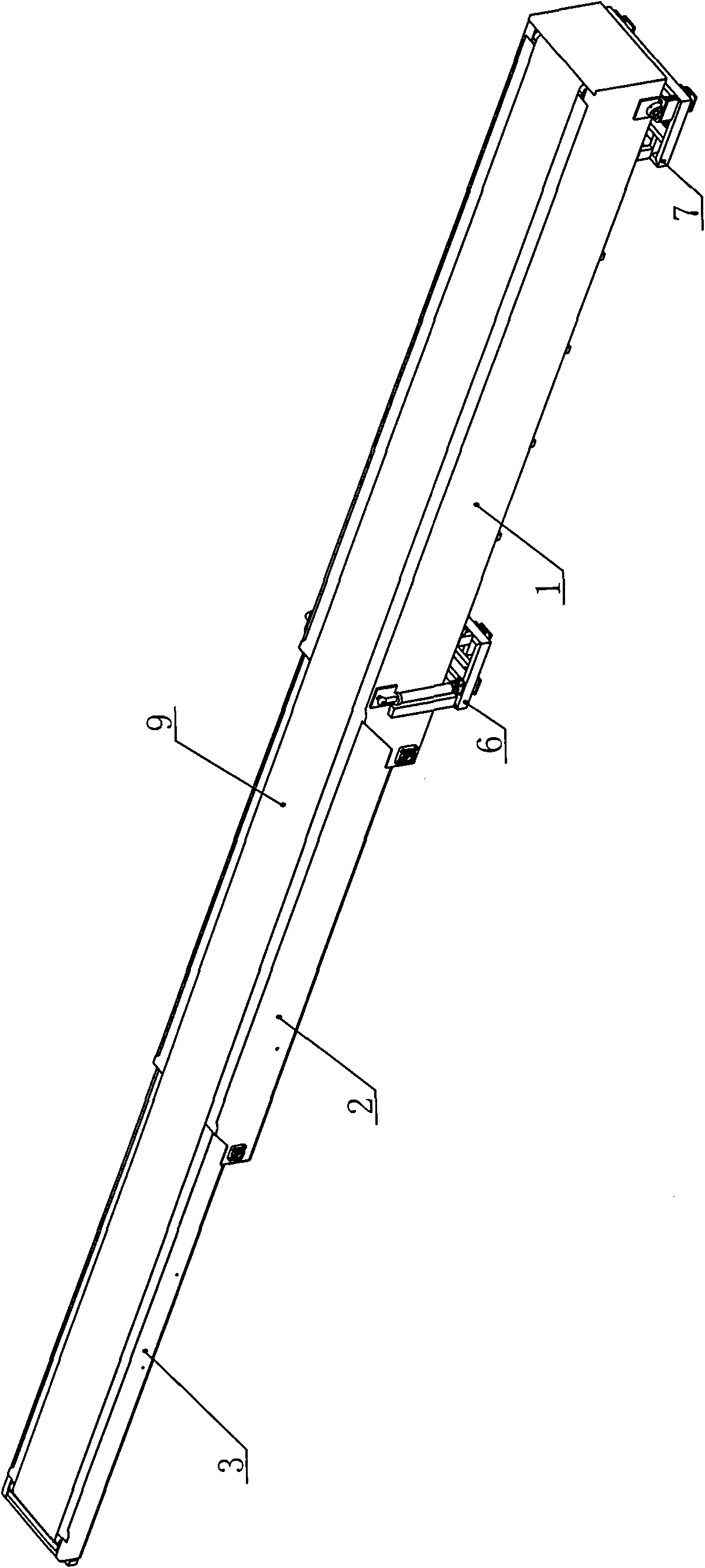

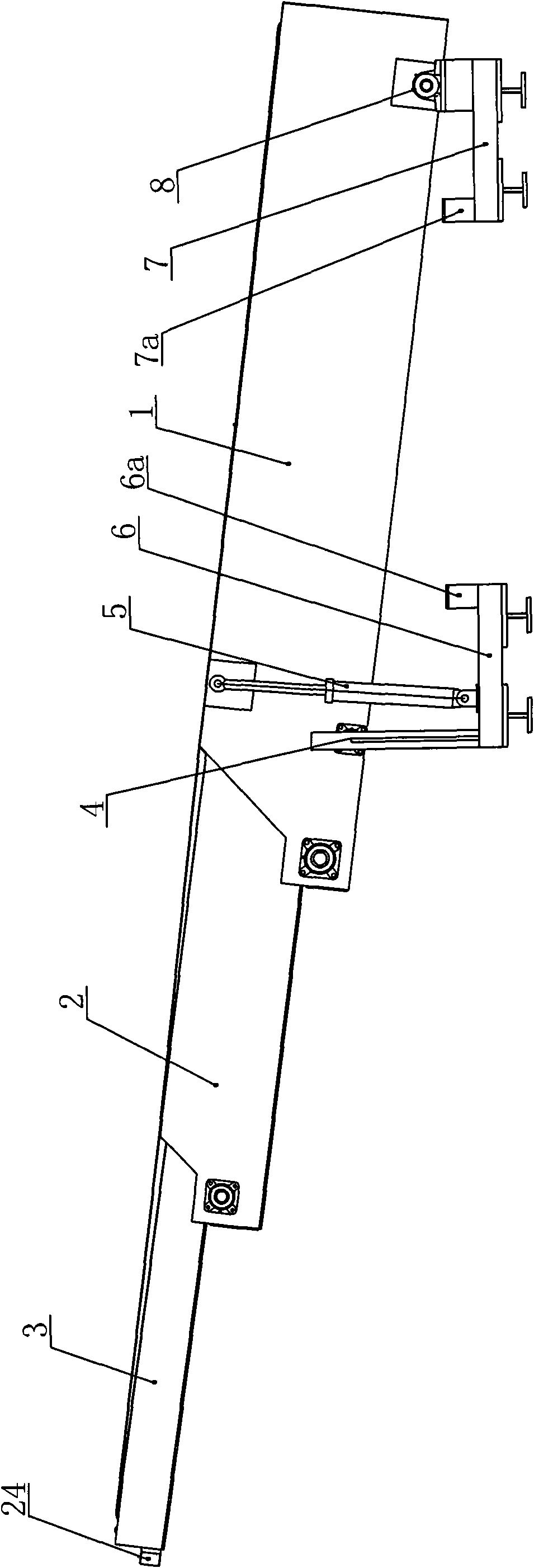

[0029] Such as figure 1 and figure 2 As shown, the telescopic two-way loading and unloading conveyor of the present invention includes a base section 1, a first-level expansion joint 2, a second-level expansion joint 3, a belt conveying mechanism, a telescopic mechanism and a lifting mechanism, and the two ends of the base section 1 are respectively provided with For the front base 6 and the rear base 7, the front base 6 is provided with a front support body 6a, and the rear base 7 is provided with a rear support body 7a. The bottoms of the front base 6 and the rear base 7 are equipped with casters and anchor screw respectively, and the bottoms of each anchor screw are respectively provided with supports. Rotate the foot screw in the opposite direction to rotate the support away from the ground. At this time, the casters are on the ground so that the loading and unloading conveyor can move to the desired location. After reaching the working position, rotate the foot screw fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com