Upper jacking system with multi-station jacking function

A multi-station, ejecting technology, applied in the field of upper ejecting system, can solve the problems of unloading or insufficient pressure of air compressor, complicated structure of mechanical upper ejecting device, unable to realize ejecting function, etc., and achieve action response. The effect of fast, strong anti-eccentric load capacity and short transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

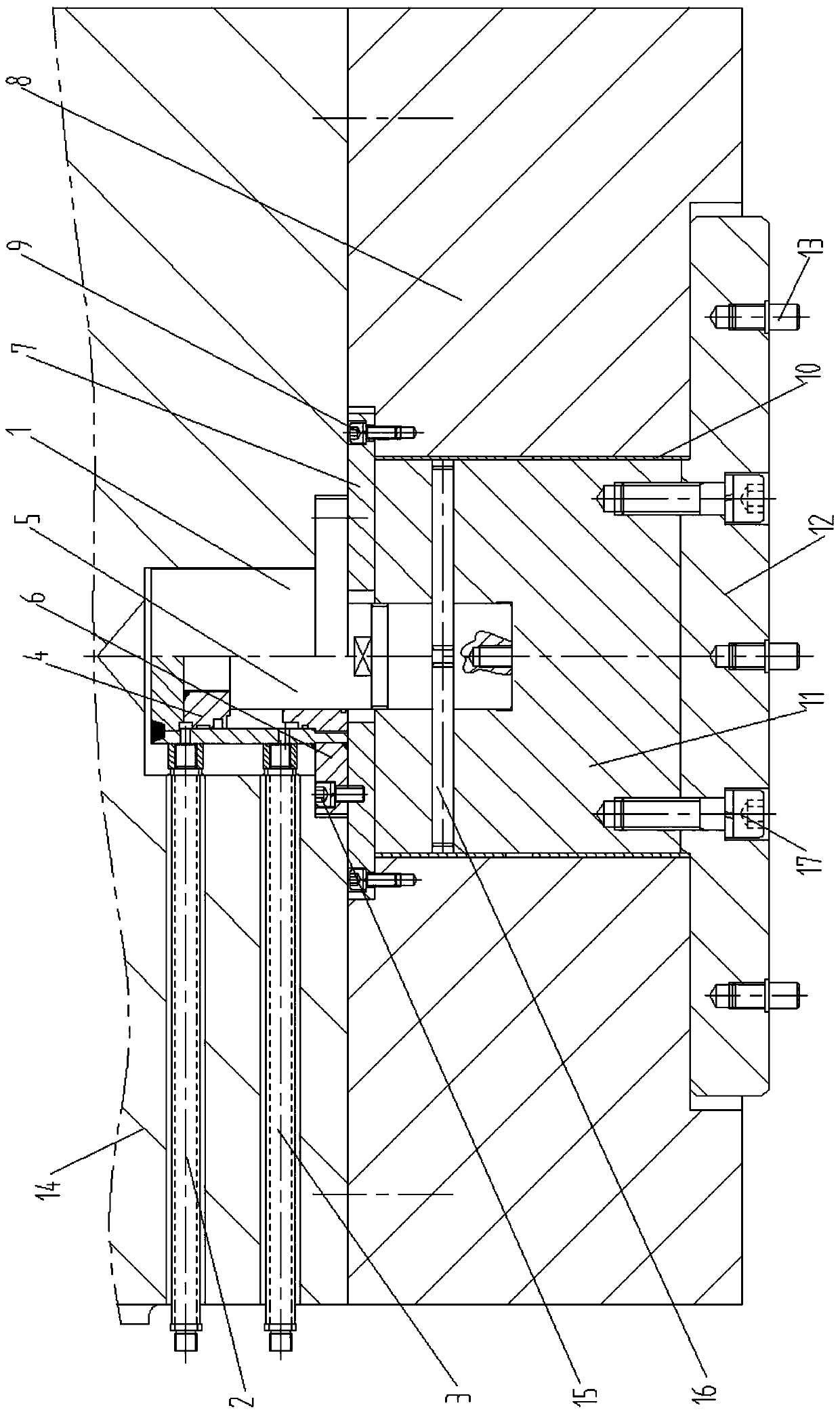

[0016] exist figure 1 Among them, the multi-station ejection jacking system of the present invention includes a hydraulic cylinder block 1 installed in the center hole of the slider 14, connected to the upper side of the hydraulic cylinder body, passing through the horizontal hole of the slider block and protruding from the side of the slider block The upper oil inlet pipeline 2 is connected with the lower end side of the hydraulic cylinder body, passes through the horizontal hole of the slider and extends out of the lower oil inlet pipeline 3 on the side of the slider, the piston 4 installed in the hydraulic cylinder body, and the piston rod installed on the piston 5. The flange 6 located in the center step hole of the slider and fixedly installed on the outer side of the hydraulic cylinder, and the stopper 7 mounted on the flange through the flange countersunk bolt 15, has a step hole in the center And tighten the base 8 installed on the bottom surface of the slider, fasten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com