Patents

Literature

50results about How to "Big jacking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

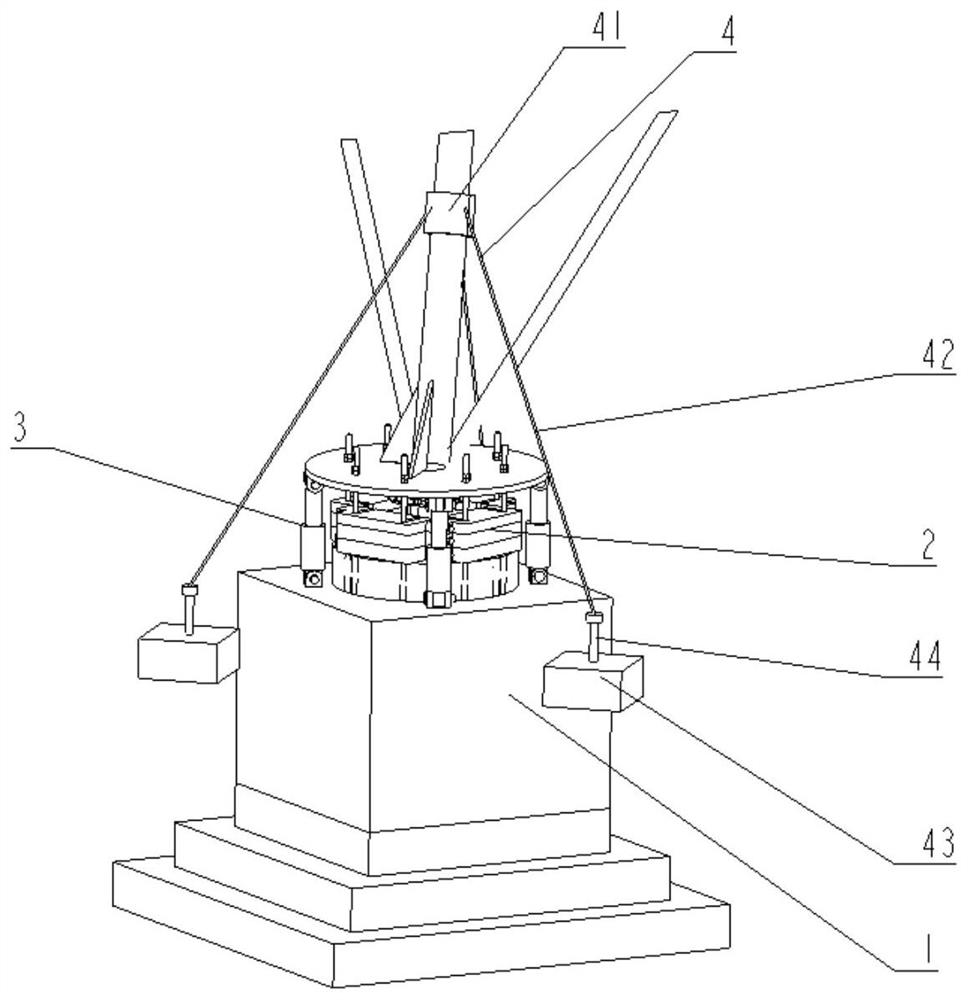

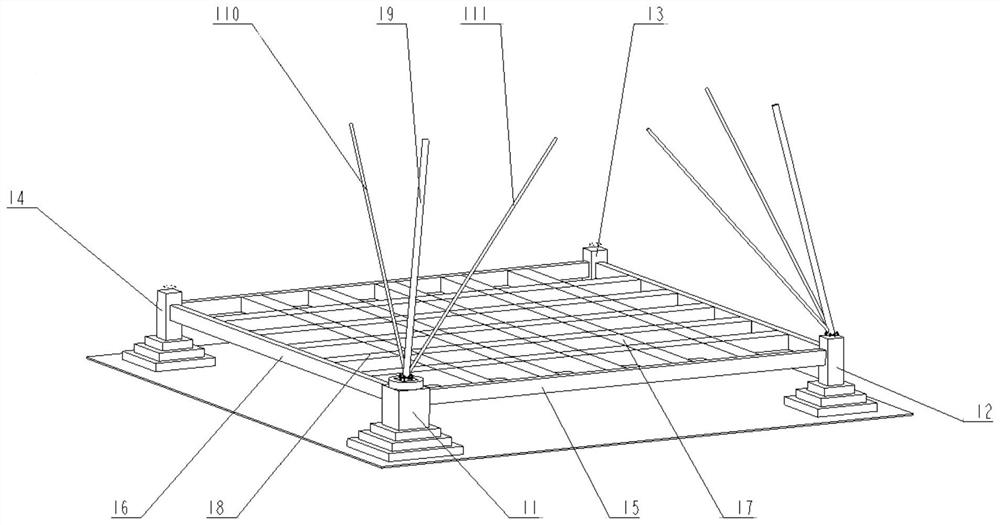

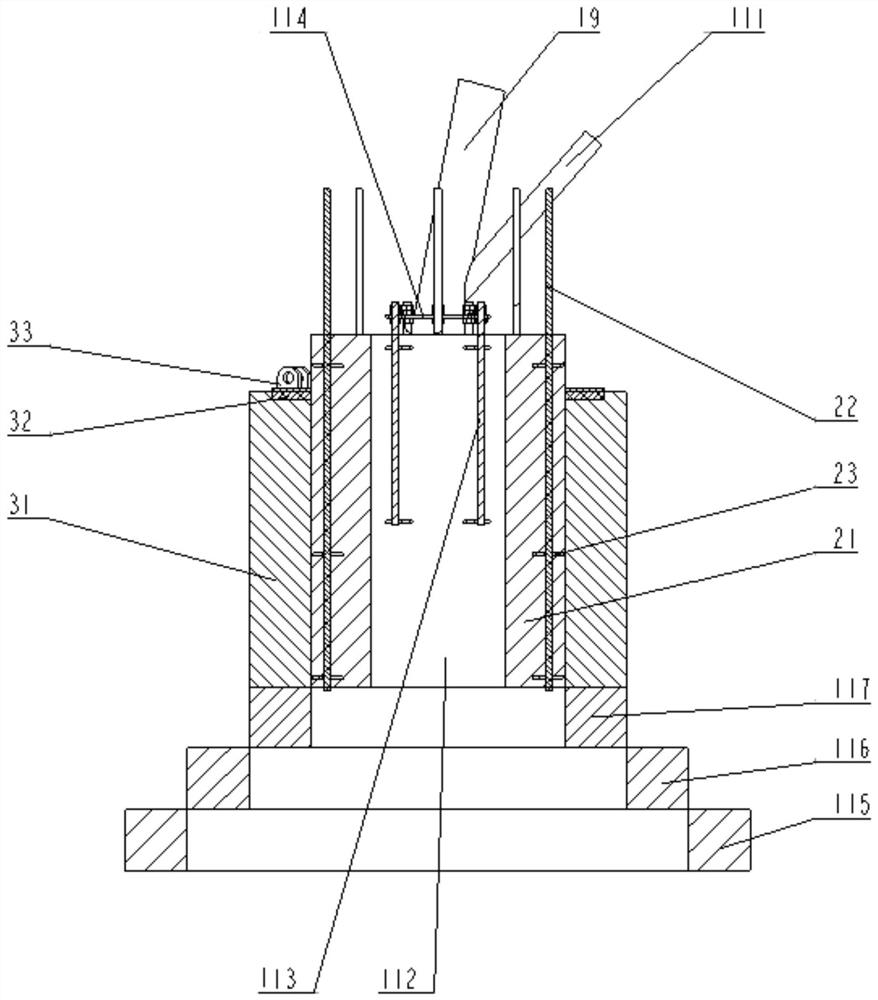

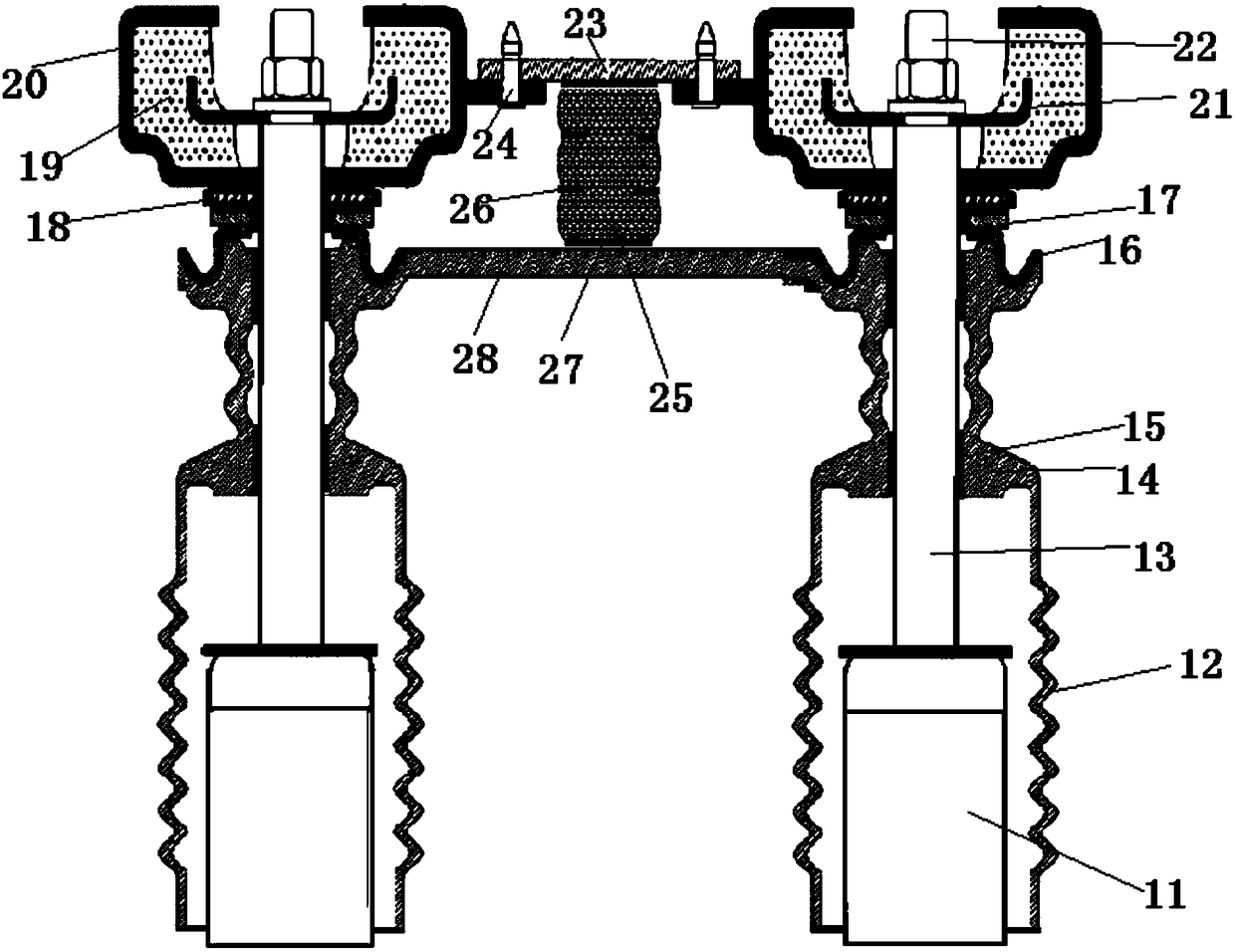

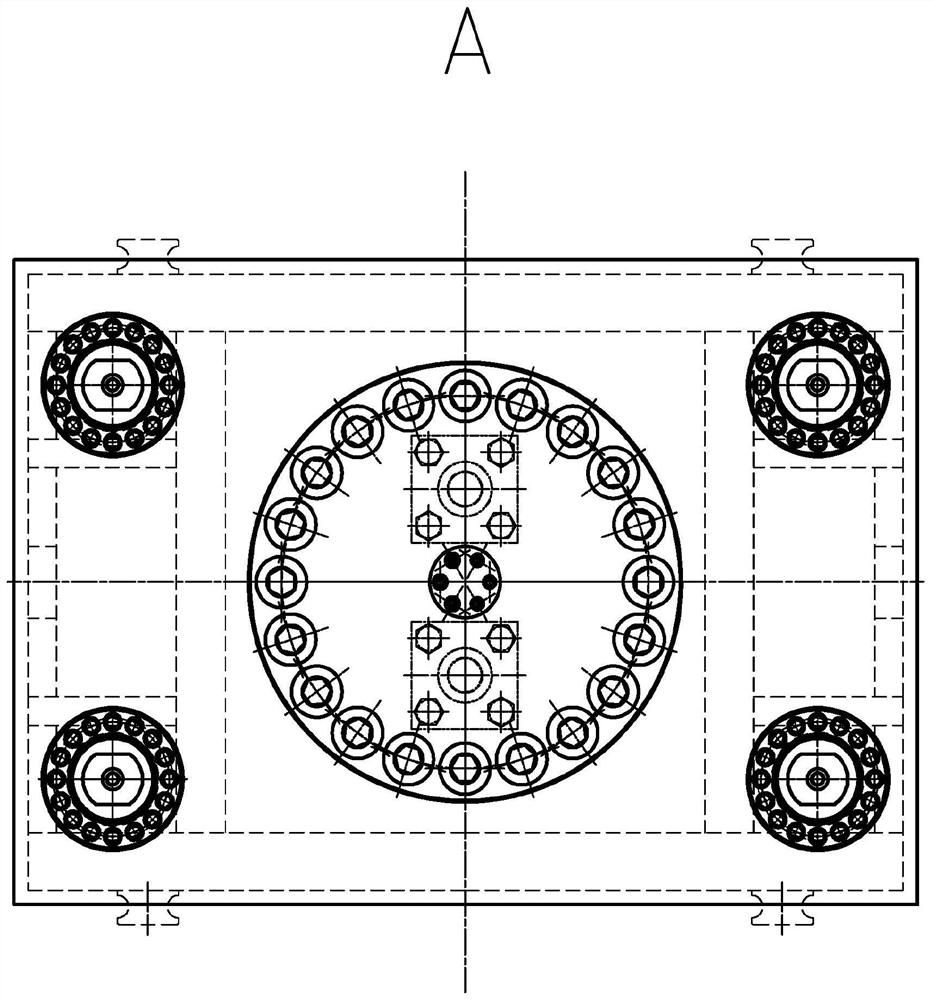

Differential settlement adjusting device of column feet of iron tower and underpinning lifting construction method

PendingCN113373996AQuick lift adjustmentStable structureFoundation engineeringTowersArchitectural engineeringTower

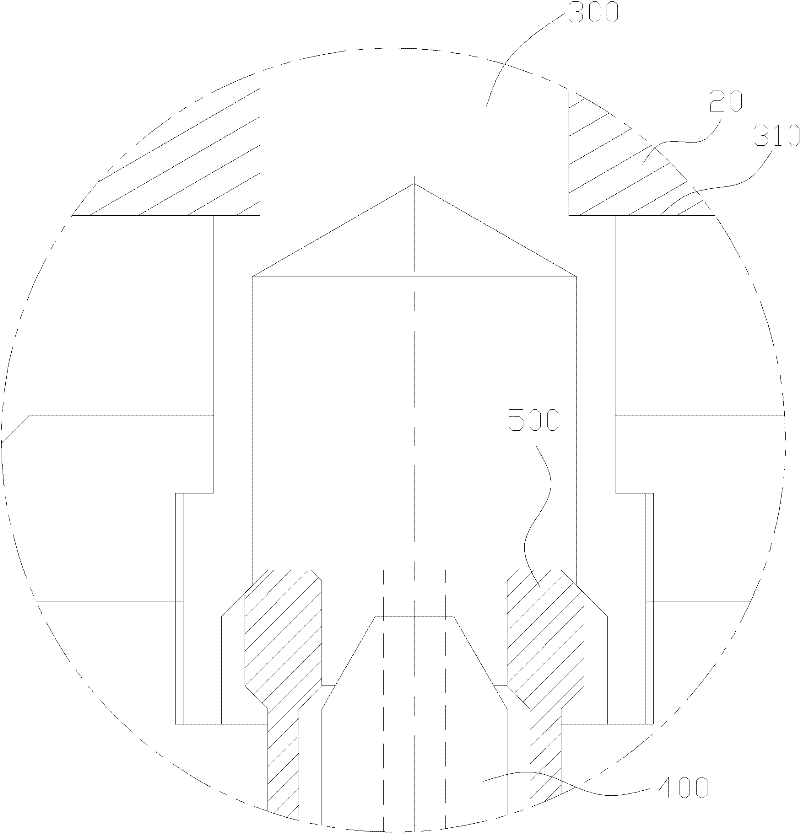

The invention discloses a differential settlement adjusting device of column feet of an iron tower and an underpinning lifting construction method. The differential settlement adjusting device of the column feet of the iron tower is characterized in that the column feet of the iron tower comprises a lower supporting stand column, and the adjusting device comprises a fixed stand column, a fixed column foot flange, a plurality of adjusting cushion blocks and a plurality of telescopic oil cylinders, wherein a plurality of evenly-distributed fixed anchor bolts are fixedly connected to the inner part of the fixed stand column. According to the differential settlement adjusting device of the column feet of the iron tower, after differential settlement of the column feet of the iron tower occurs, the column feet of the iron tower can be rapidly lifted and adjusted, so that the multiple column feet of the iron tower are always in the same horizontal plane, and the structure is kept stable; the differential settlement adjusting device of the column feet of the iron tower has pressure-bearing and anti-pulling functions, can provide large jacking force and can bear large anti-pulling force in the lifting process of the column feet; after the column feet are adjusted to the set height, fixing is convenient, and long-term efficient operation is kept; the differential settlement of a high and large iron tower foundation in an area with large wind power can be effectively adjusted, and the differential settlement can be repeatedly adjusted according to the settlement condition.

Owner:徐州中矿岩土技术股份有限公司

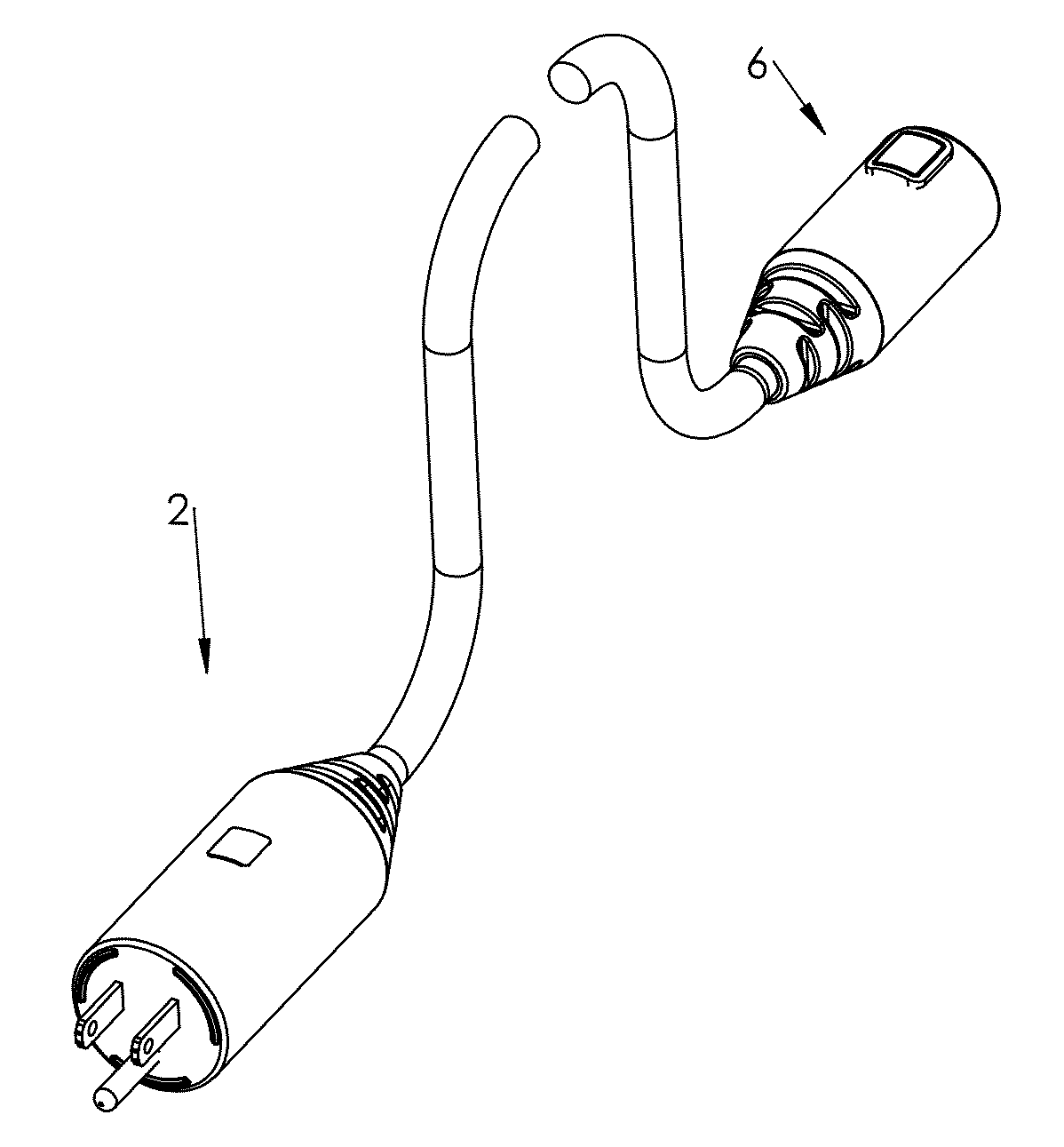

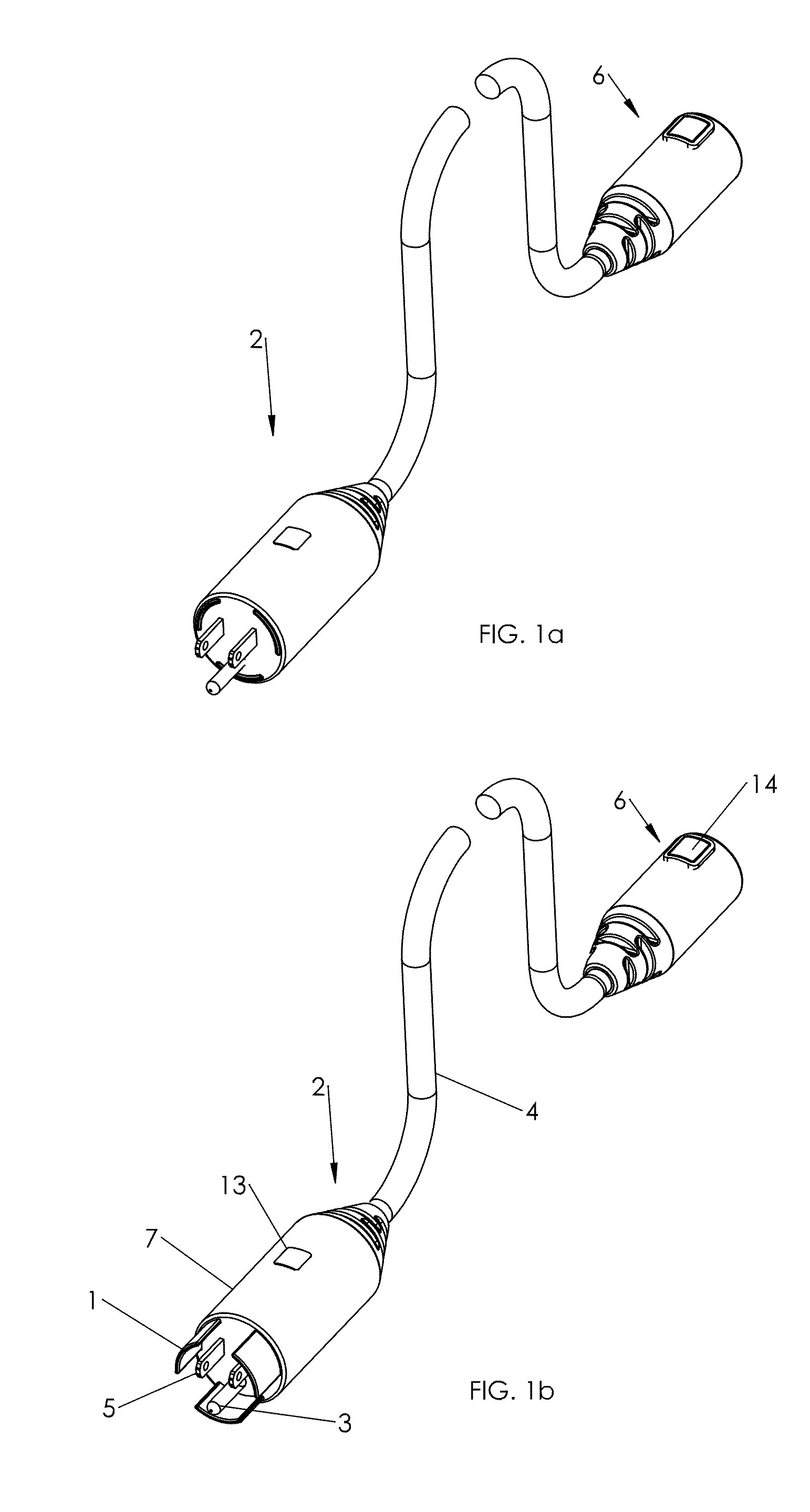

Electrical cord plug eject mechanism

InactiveUS20150364866A1Reduce pressureAvoid damageEngagement/disengagement of coupling partsTwo pole connectionsMating connectionControl signal

A plug housing includes an ejector mechanism and a controller electrically coupled to the ejector mechanism for detaching electrical conductive blades of the plug from a mated connection with a female connector. In response to a switch signal from the controller, a solenoid is activated to release a latch in the mechanism, thereby permitting the force of a compressed spring to impel a structure outwardly from the plug. The controller may be located remotely from the plug and superimpose control signals to the plug over the power lines within the cord.

Owner:BRAINWAVE RES CORP

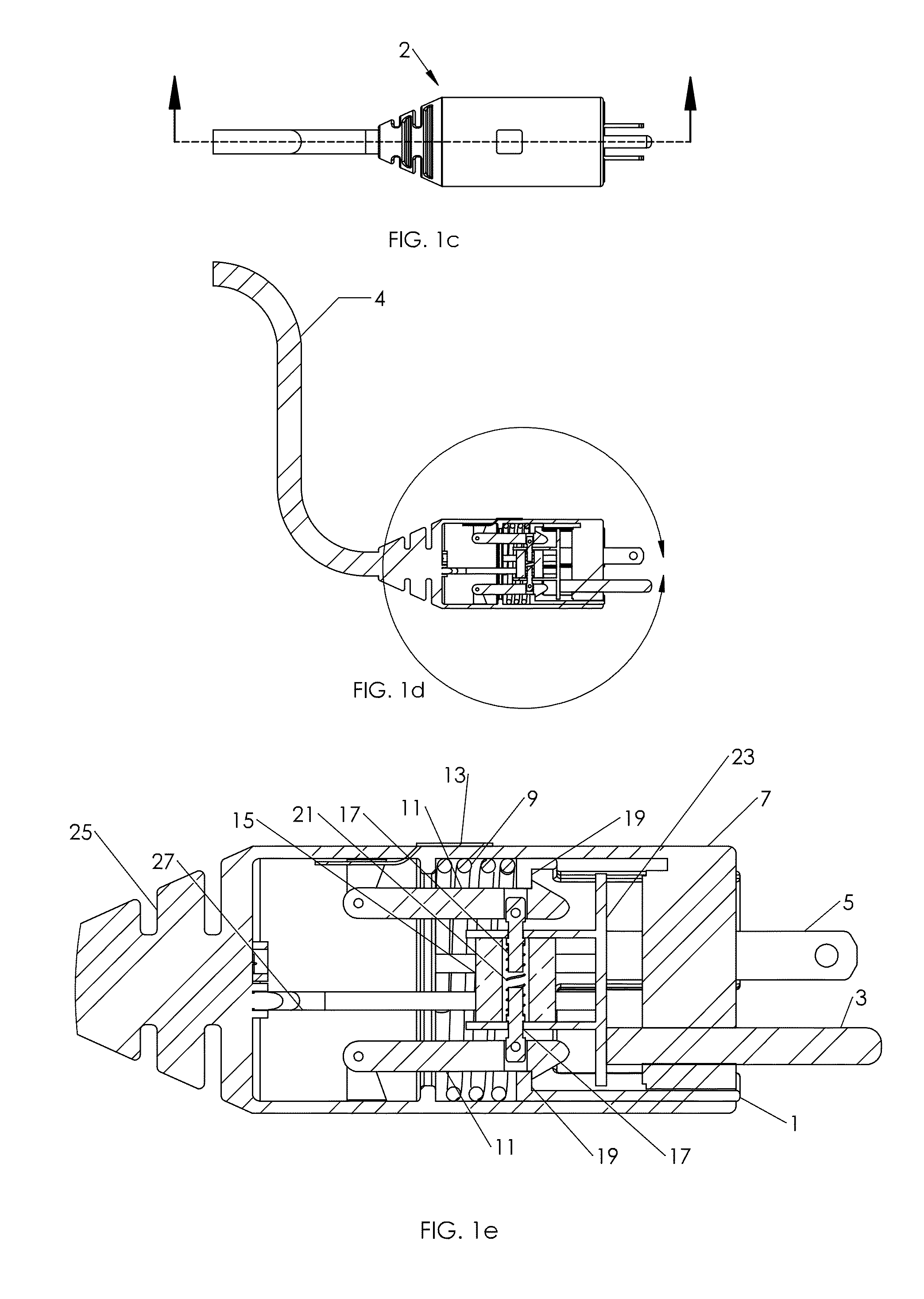

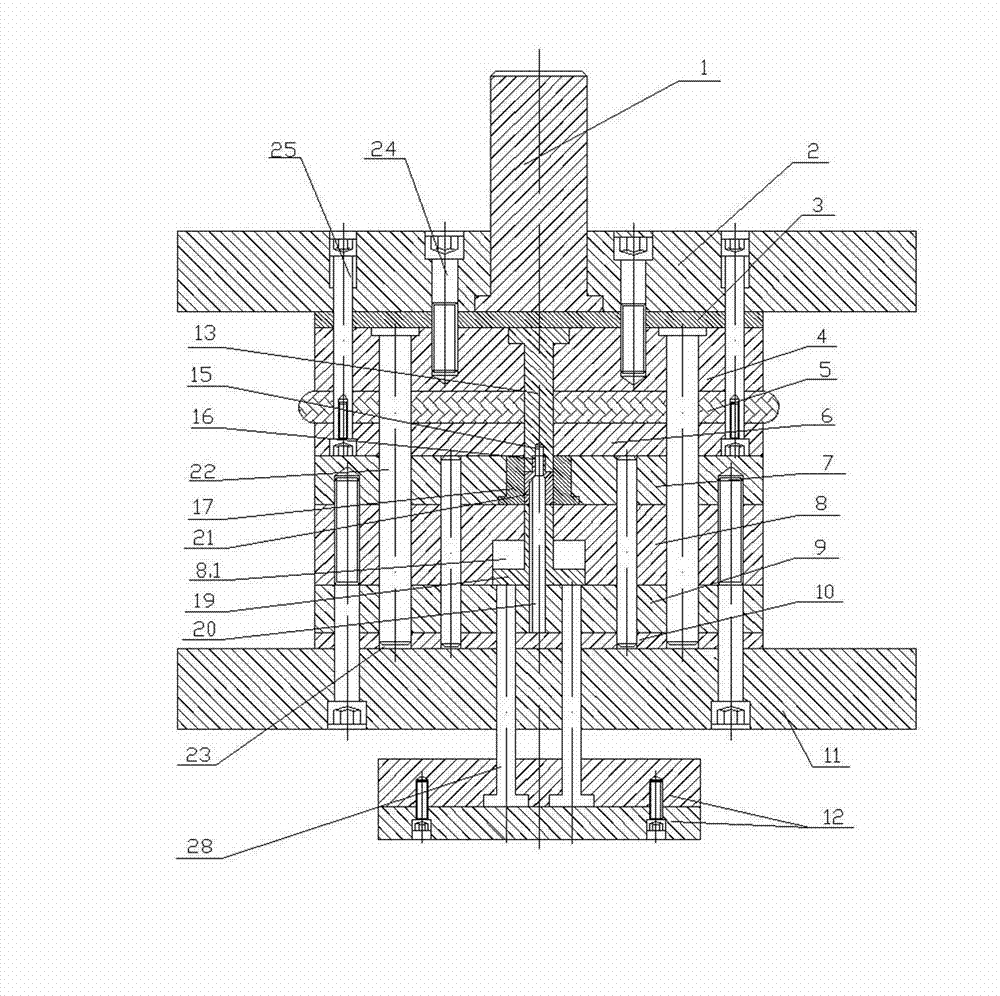

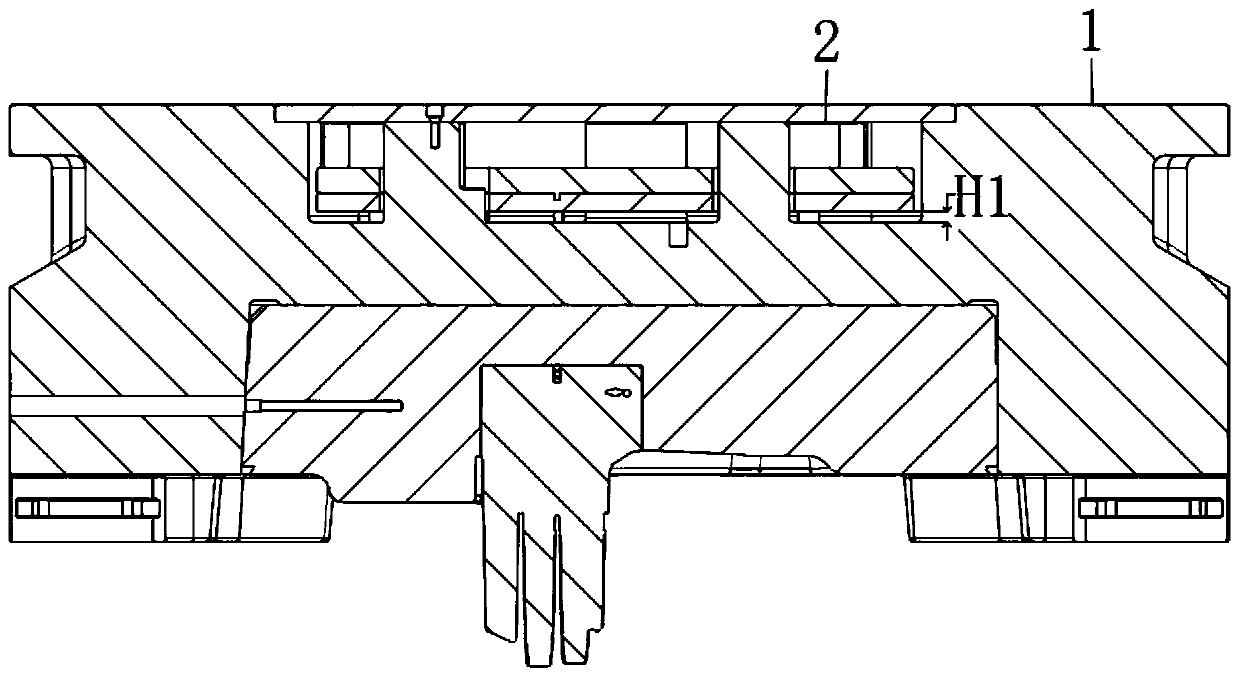

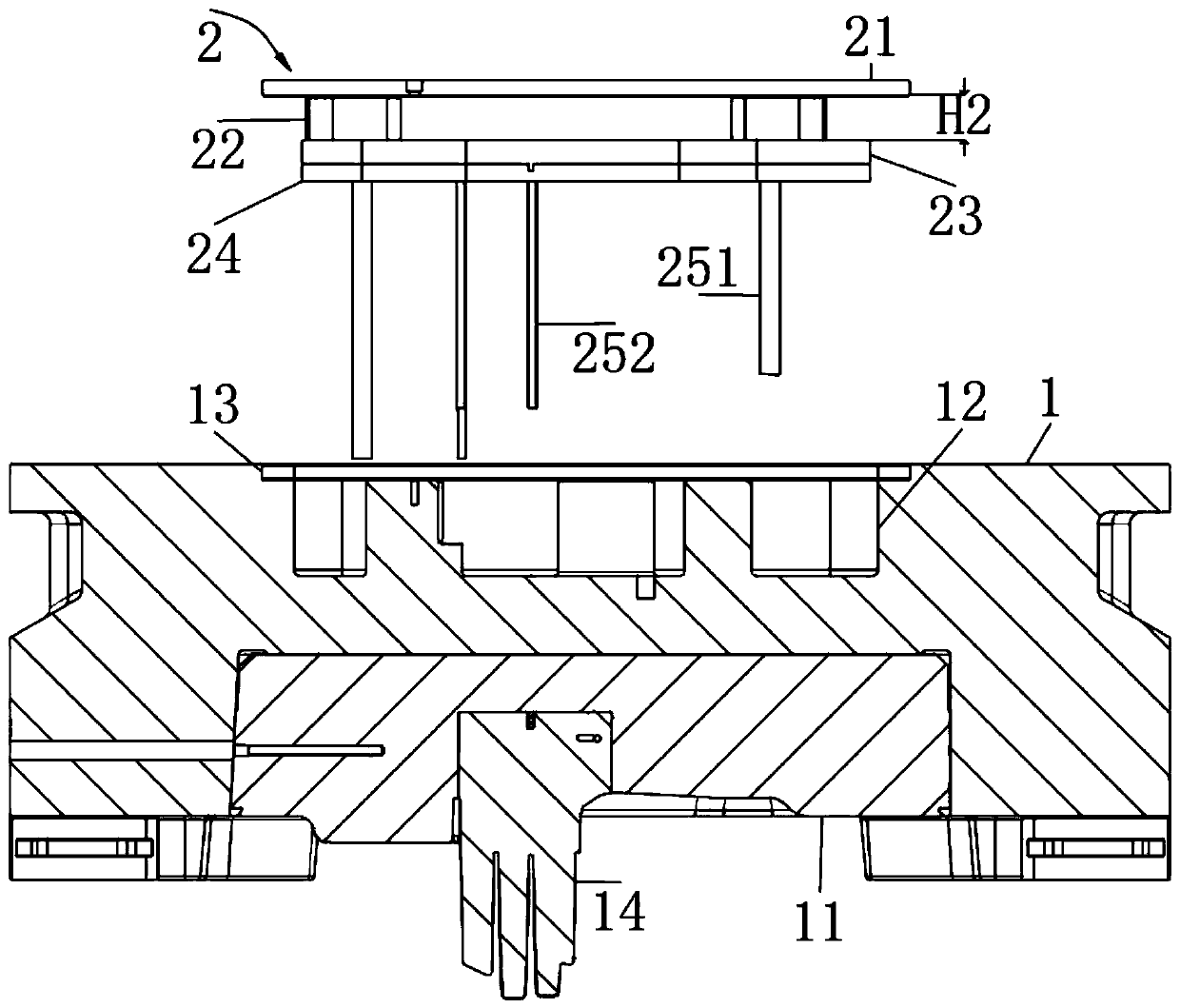

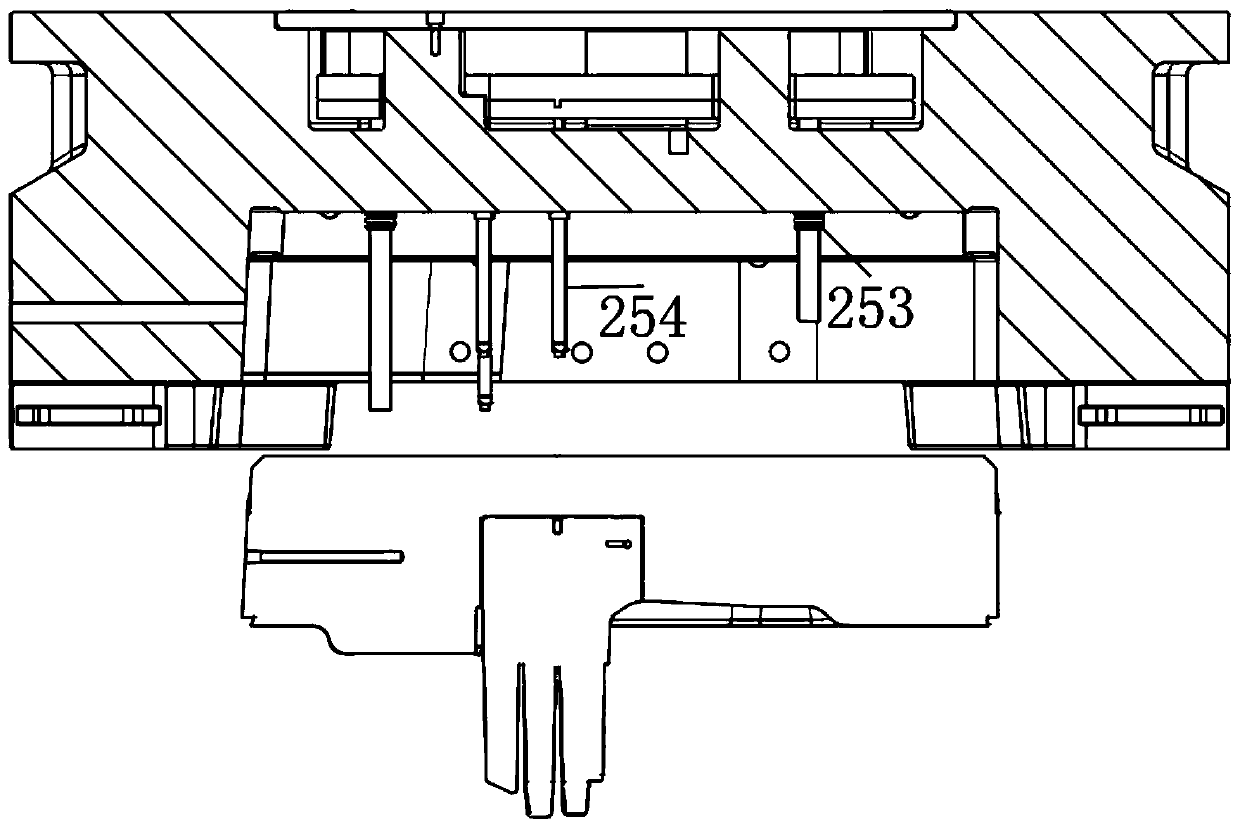

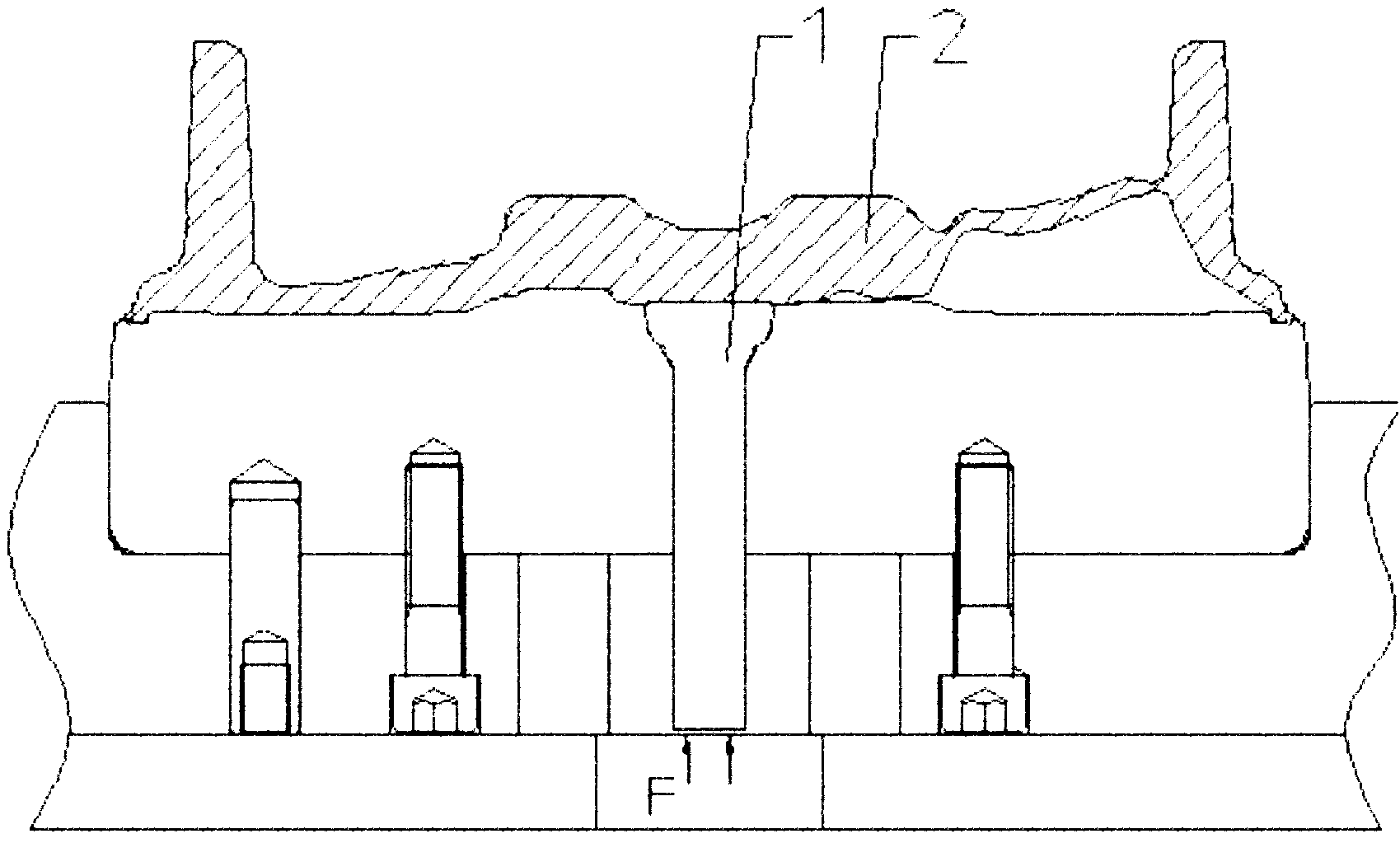

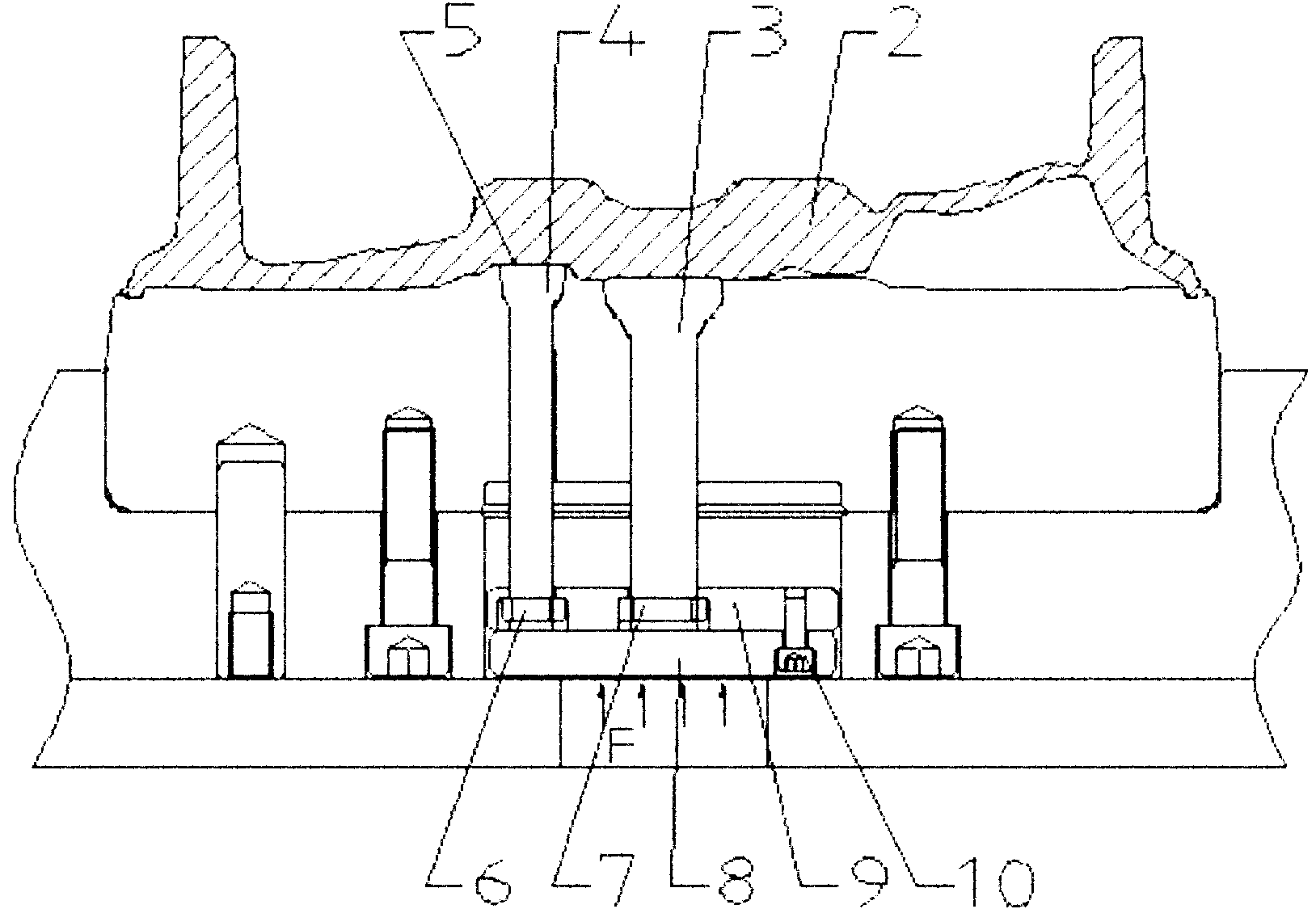

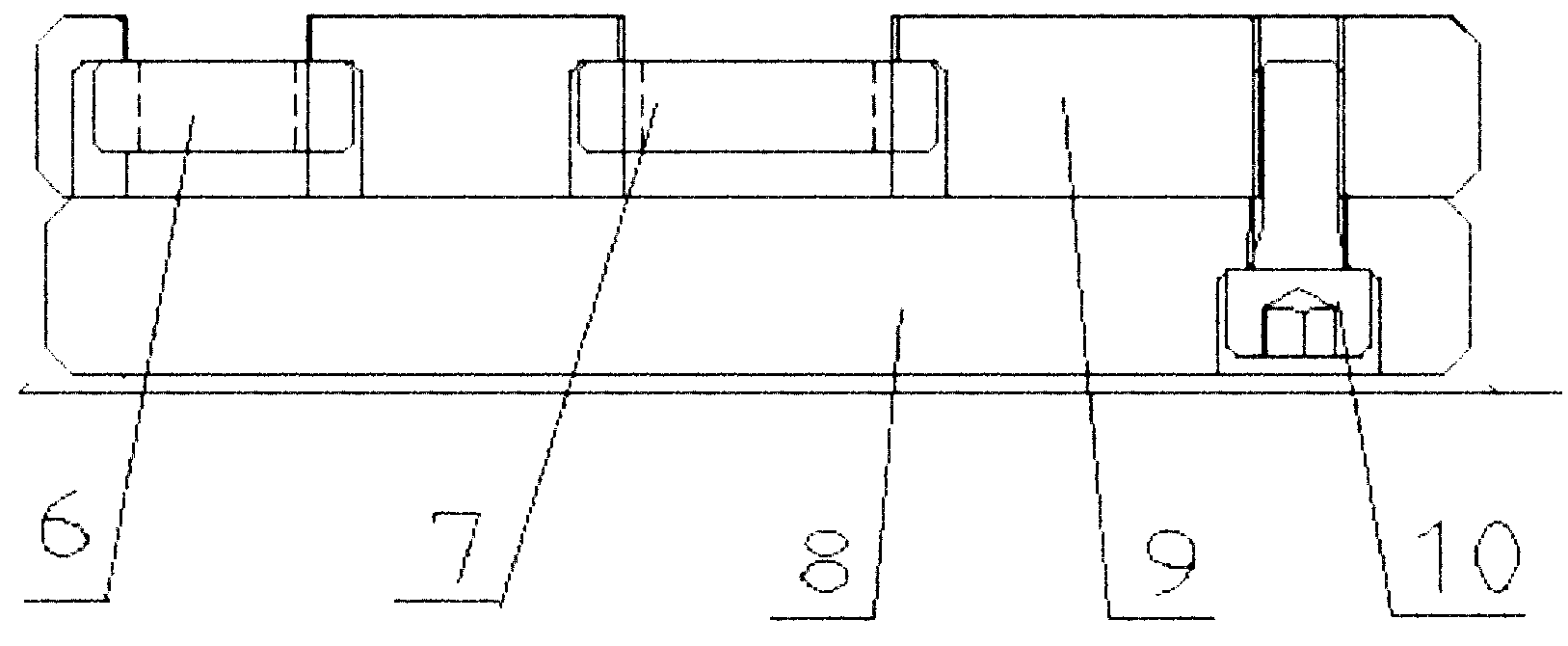

Hot-extrusion die of axial copper lock body

The invention discloses a hot-extrusion die of an axial copper lock body. The hot-extrusion die comprises an upper die and a lower die, wherein the upper die comprises a die handle, an upper die plate, an upper die cushion plate, an upper fixing plate with an upper male die, an elastomer and a stripping cushion plate, which are sequentially connected from top to bottom; the lower die comprises a female die sleeve with a lower female die, a moving die sleeve with a moving die, a lower fixing plate, a lower die cushion plate, a lower die plate and a jacking rod fixing plate with a jacking rod; a guide hole and a first forming hole are sequentially formed in the upper male die from top to bottom; a second forming hole is formed in the lower female die; the guide hole is glidingly matched with a cylindrical head of a lower die core of which the lower end pushes against the lower die cushion plate and the upper end penetrates through the moving die and protrudes through the second forming hole; the lower die core also comprises a core rod consisting of a cylindrical rod and a square rod arranged on one side of the cylindrical rod; an inclined surface is arranged at the connecting place between the cylindrical rod and the cylindrical head of the core rod; and an arc surface is arranged at the connecting place between the square rod of the core rod and the inclined surface. By the hot-extrusion die of the axial copper lock body, the production efficiency and the product quality can be improved.

Owner:佛山市深威金属制品有限公司

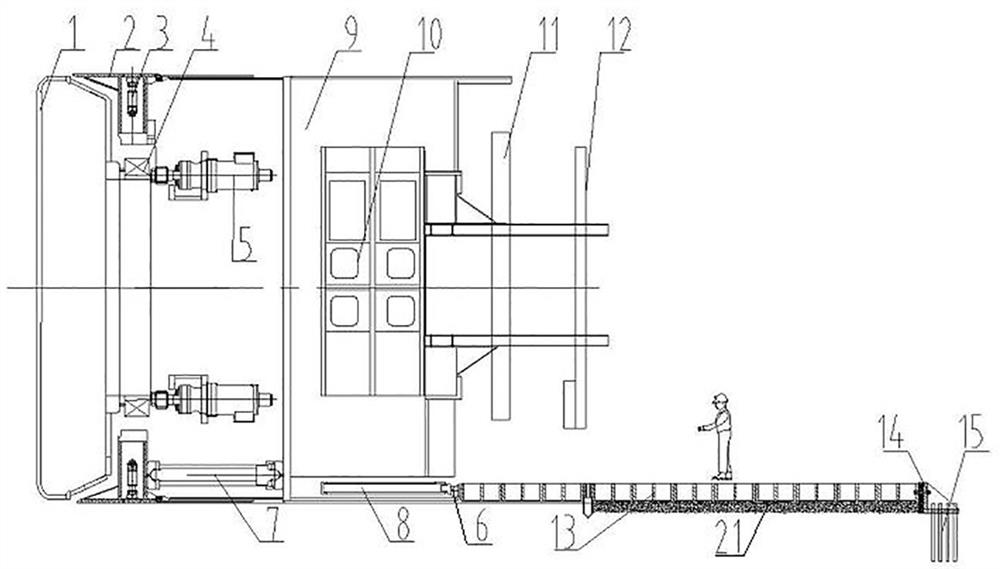

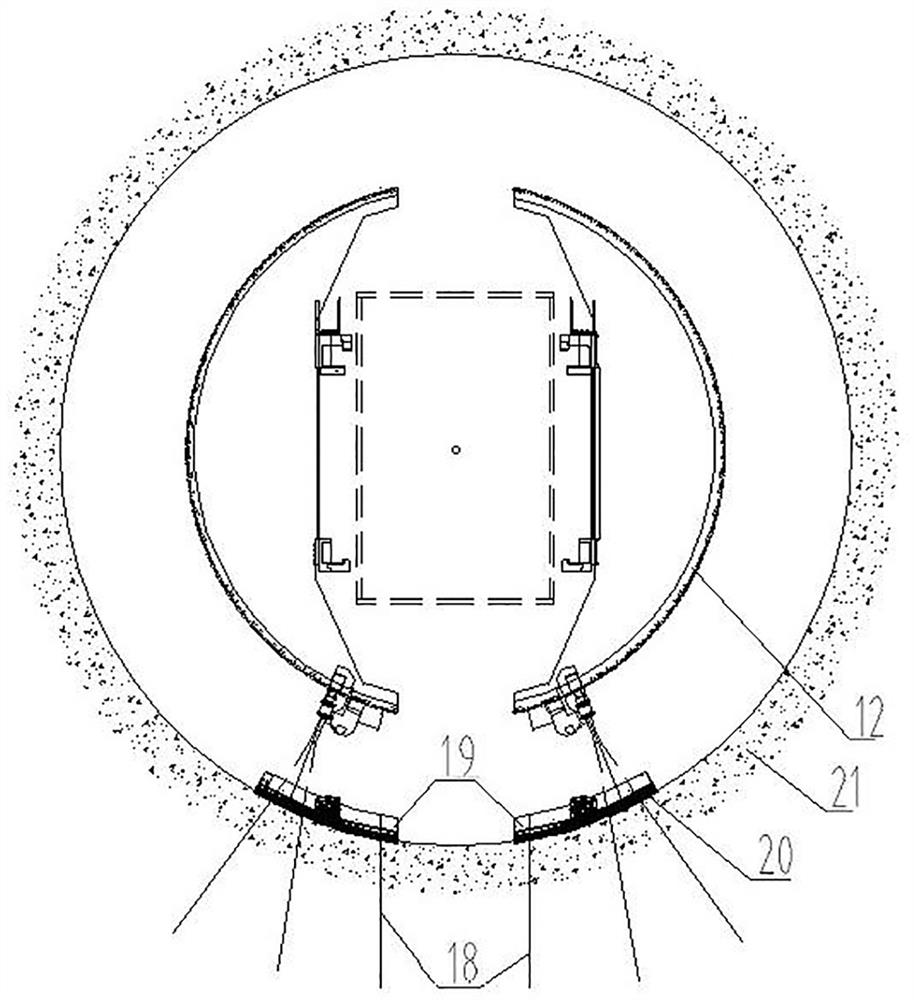

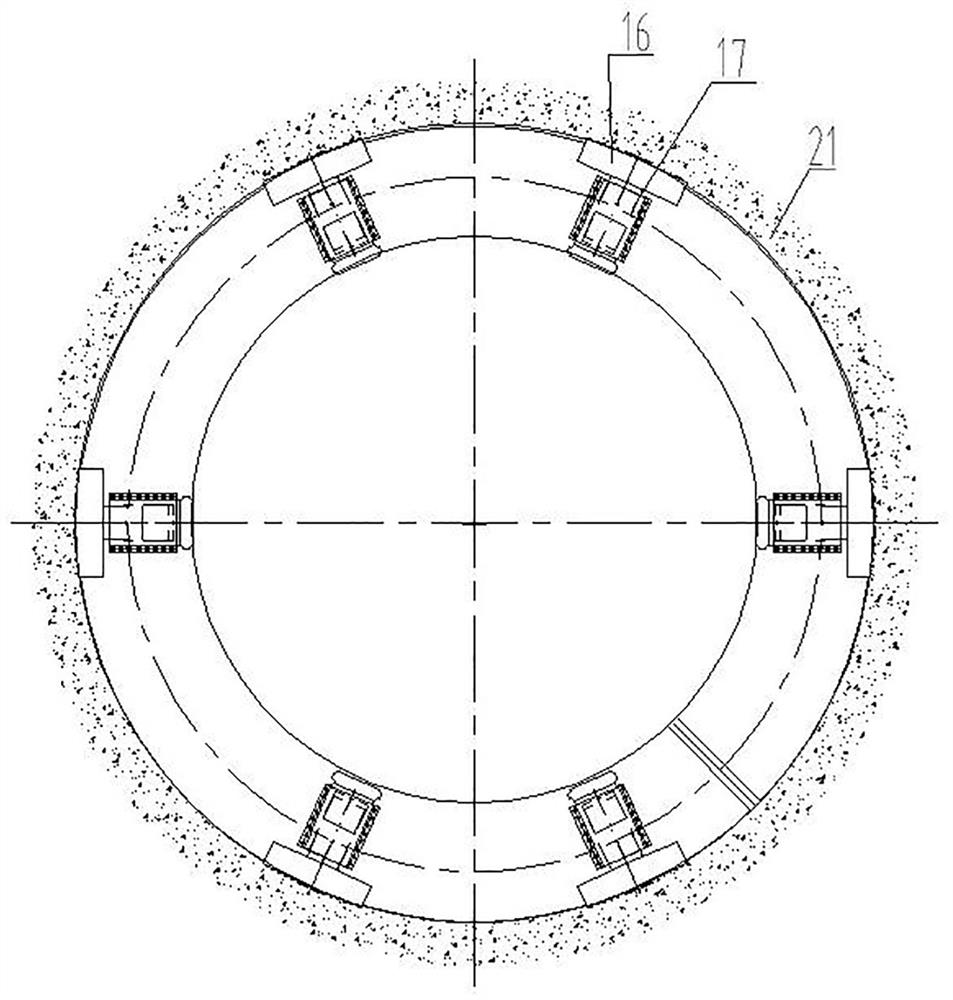

Inclined shaft TBM tunneling system and tunneling method

PendingCN113217001AEasy to excavateBack slipUnderground chambersTunnel liningClassical mechanicsTunnel wall

The invention relates to an inclined shaft TBM tunneling system and tunneling method. The inclined shaft TBM tunneling system comprises an anterior shield, a supporting shield, a supporting shoe assembly, a supporting assembly and an axial anti-slip oil cylinder, wherein a driving device is arranged in the anterior shield, a cutterhead is arranged at the front end of the anterior shield, and the driving device is used for driving the cutterhead to rotate; the front end of the supporting shield is inserted into the rear end of the front shield or arranged at the rear end of the front shield in a sleeving mode, and a thrust oil cylinder is arranged between the supporting shield and the front shield so that the front shield can move forwards relative to the supporting shield in the front-back direction; the supporting shoe assembly is arranged in the supporting shield, and the supporting shoe assembly and the thrust oil cylinder work cooperatively so as to achieve step changing of the inclined shaft TBM; the supporting assembly is arranged behind the supporting shield, the supporting assembly comprises an arch frame and an arch frame anchor rod, the arch frame anchor rod is inserted into the tunnel wall of a tunnel, and the arch frame is installed on the arch frame anchor rod and is attached to the tunnel wall; and the axial anti-slip oil cylinder extends in the front-back direction of the tunnel and is arranged in the supporting shield, and an axial supporting shoe is arranged at the driving end of the axial anti-slip oil cylinder and used for being supported on the arch frame so as to prevent the inclined shaft TBM from slipping.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

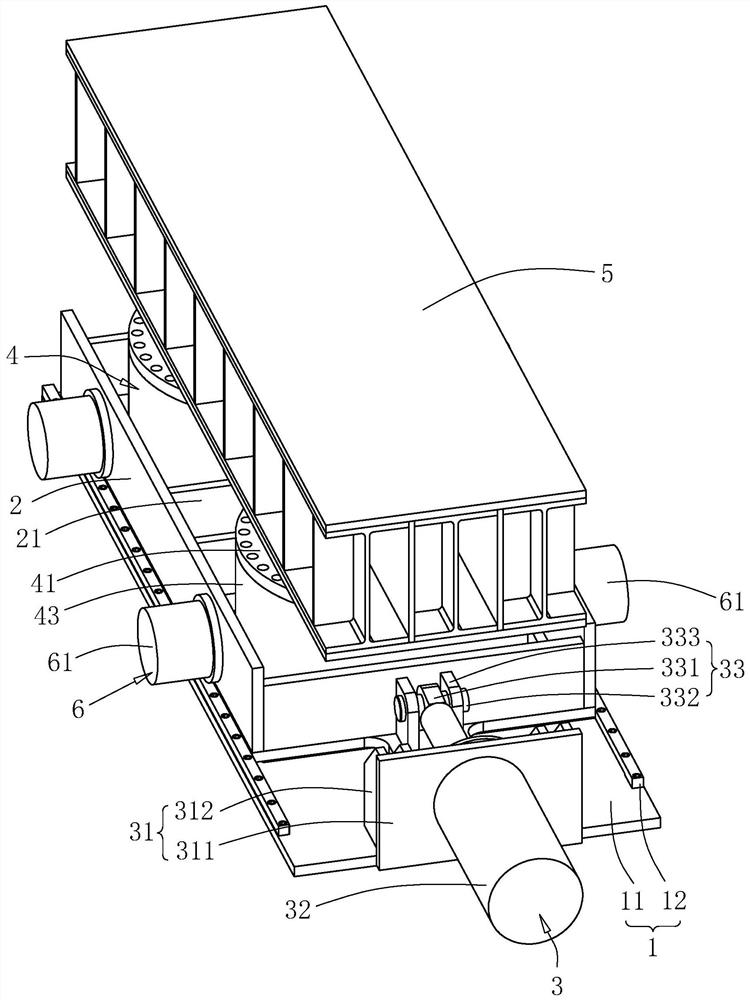

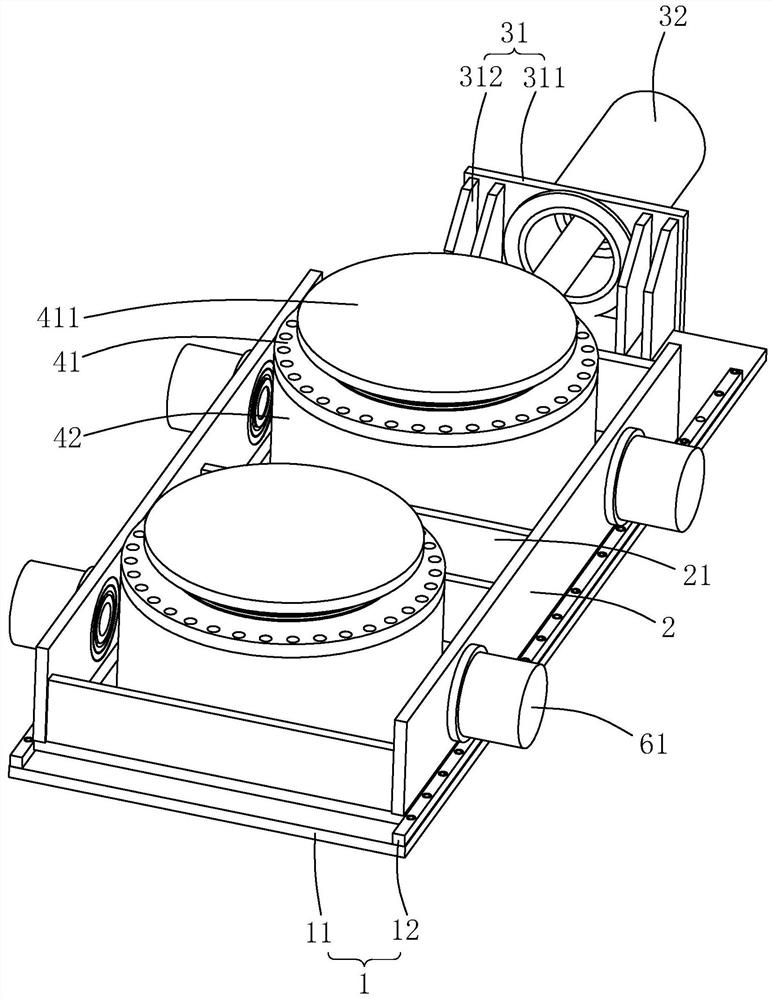

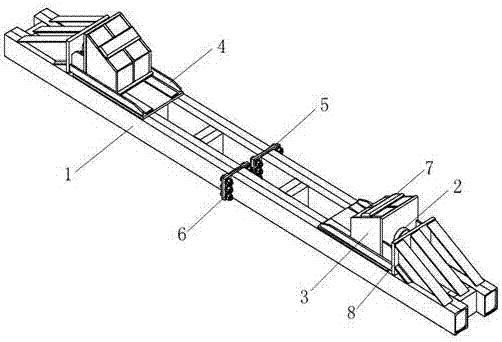

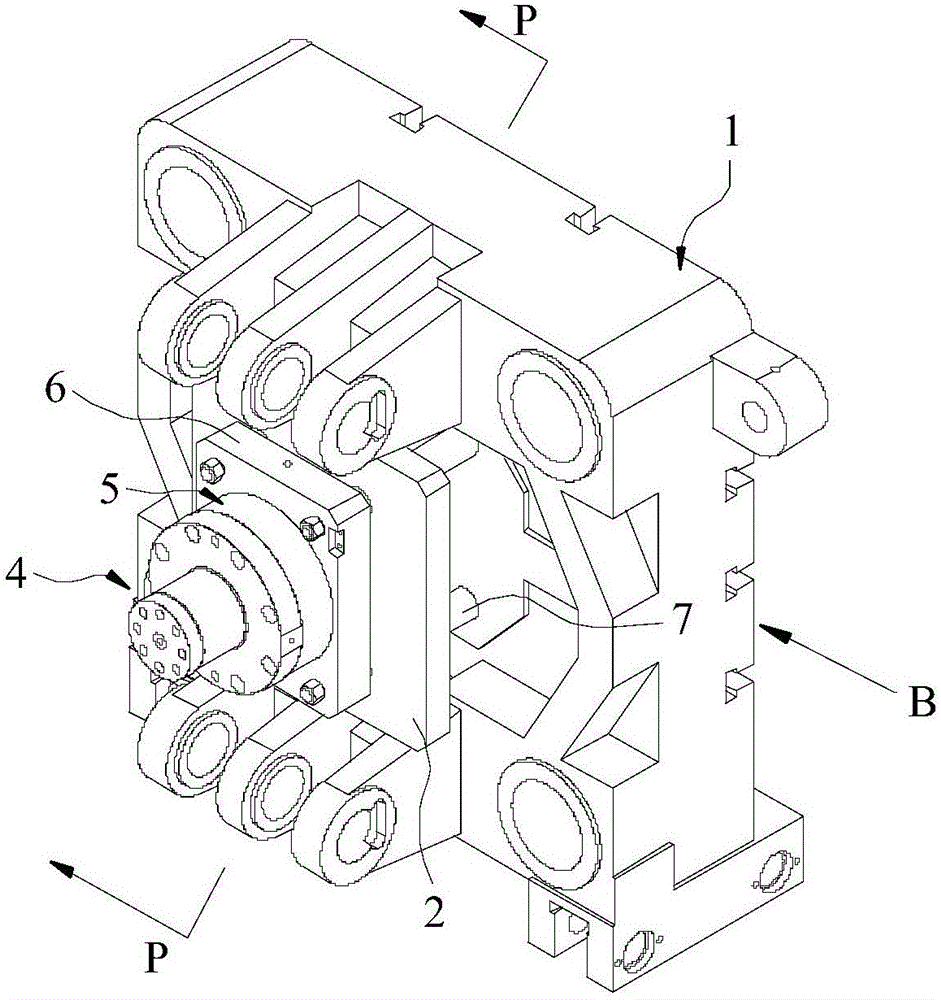

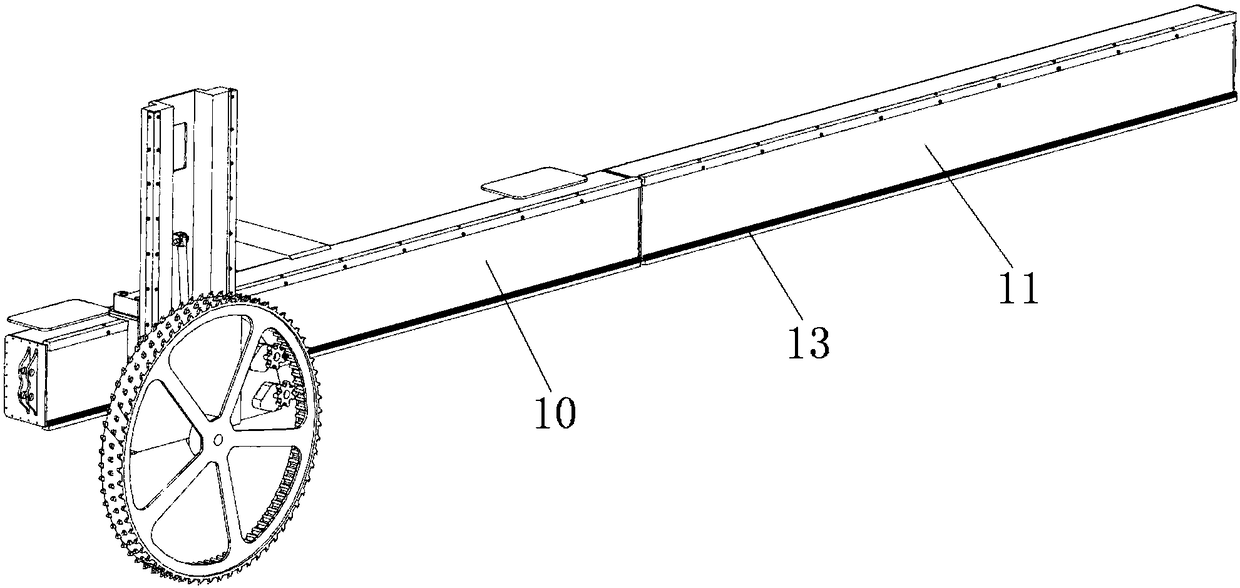

Reciprocating pulling type super-tonnage steel box girder continuous traction device and using method thereof

InactiveCN113005912AReduce the amount of constructionSimple structureBridge erection/assemblyArchitectural engineeringStructural engineering

The invention relates to a reciprocating pulling type super-tonnage steel box girder continuous traction device and a using method thereof. The traction device comprises an anchoring base, a main frame, a traction mechanism and a jacking mechanism. The main frame is slidably arranged on the anchoring base, the traction mechanism is fixedly arranged on the anchoring base, the traction mechanism is used for driving the main frame to slide back and forth in the length direction of the anchoring base, and the jacking mechanism is arranged in the main frame. The using method comprises the steps: erecting the temporary piers, installing the traction device on the temporary piers, hoisting the steel box girders to the temporary piers, assembling the steel box girder sections, controlling the jacking mechanism to conduct synchronous jacking, and jacking up the steel box girder sections; controlling the traction mechanism to drive the whole steel box girder section to advance; controlling the traction device jacking mechanism to reset, so the steel box girder sections are parked to the temporary piers; controlling the traction mechanism to reset; and repeating the control process of the traction device until the steel box girder section is in place. The construction method has the effects of reducing the work amount during installation and construction of the super-tonnage steel box girder and improving the construction efficiency.

Owner:中交二公局第五工程有限公司

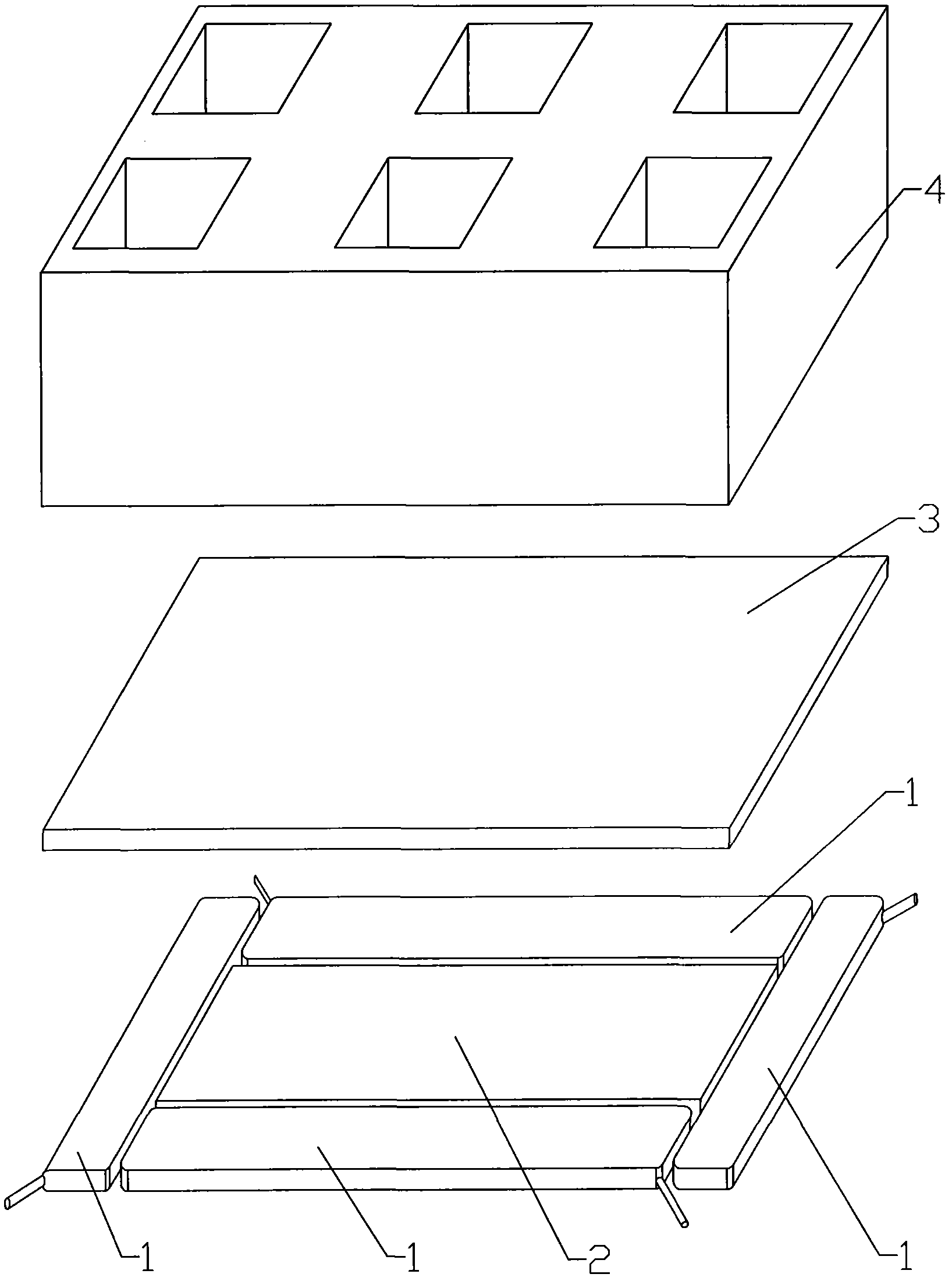

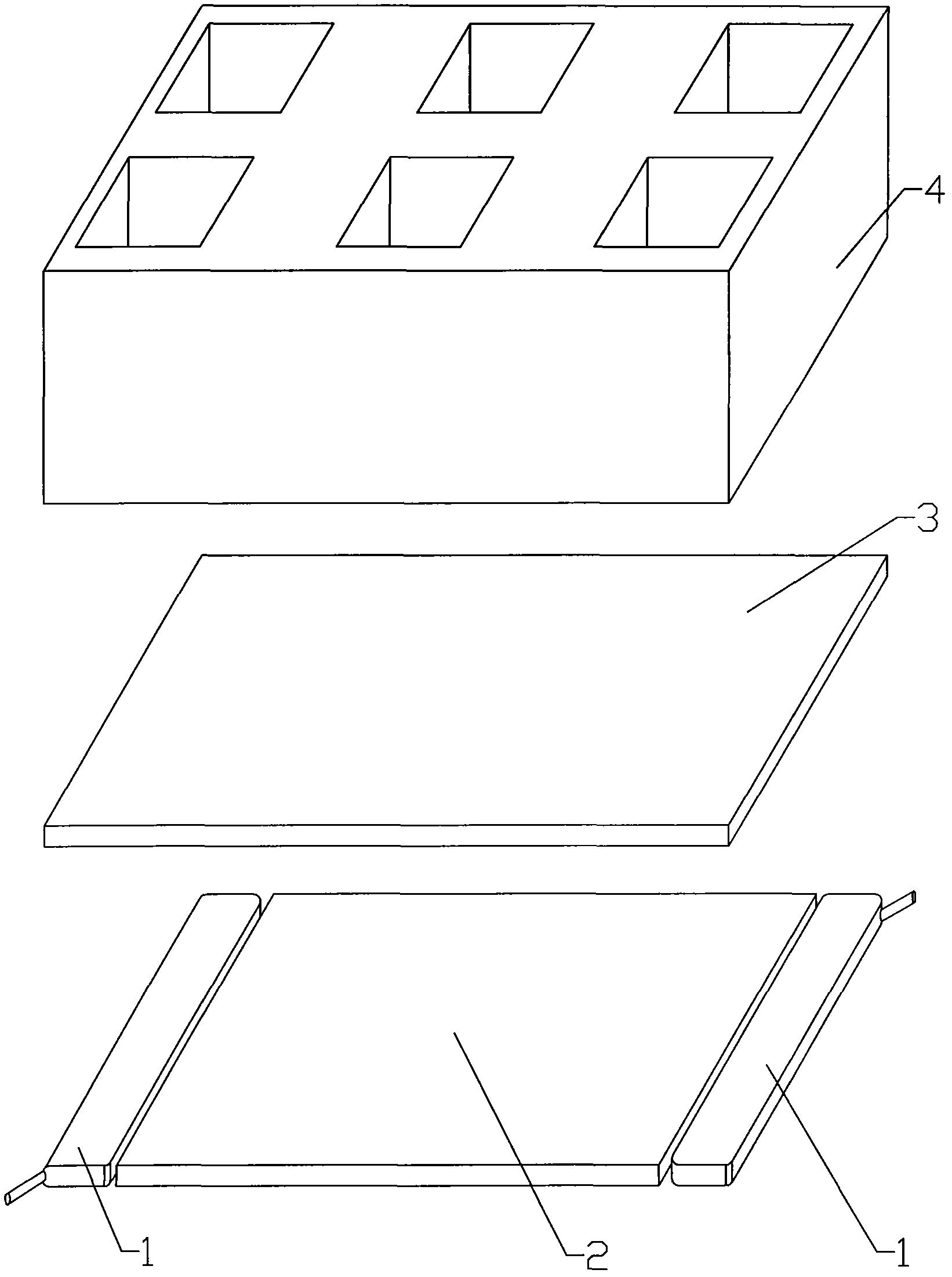

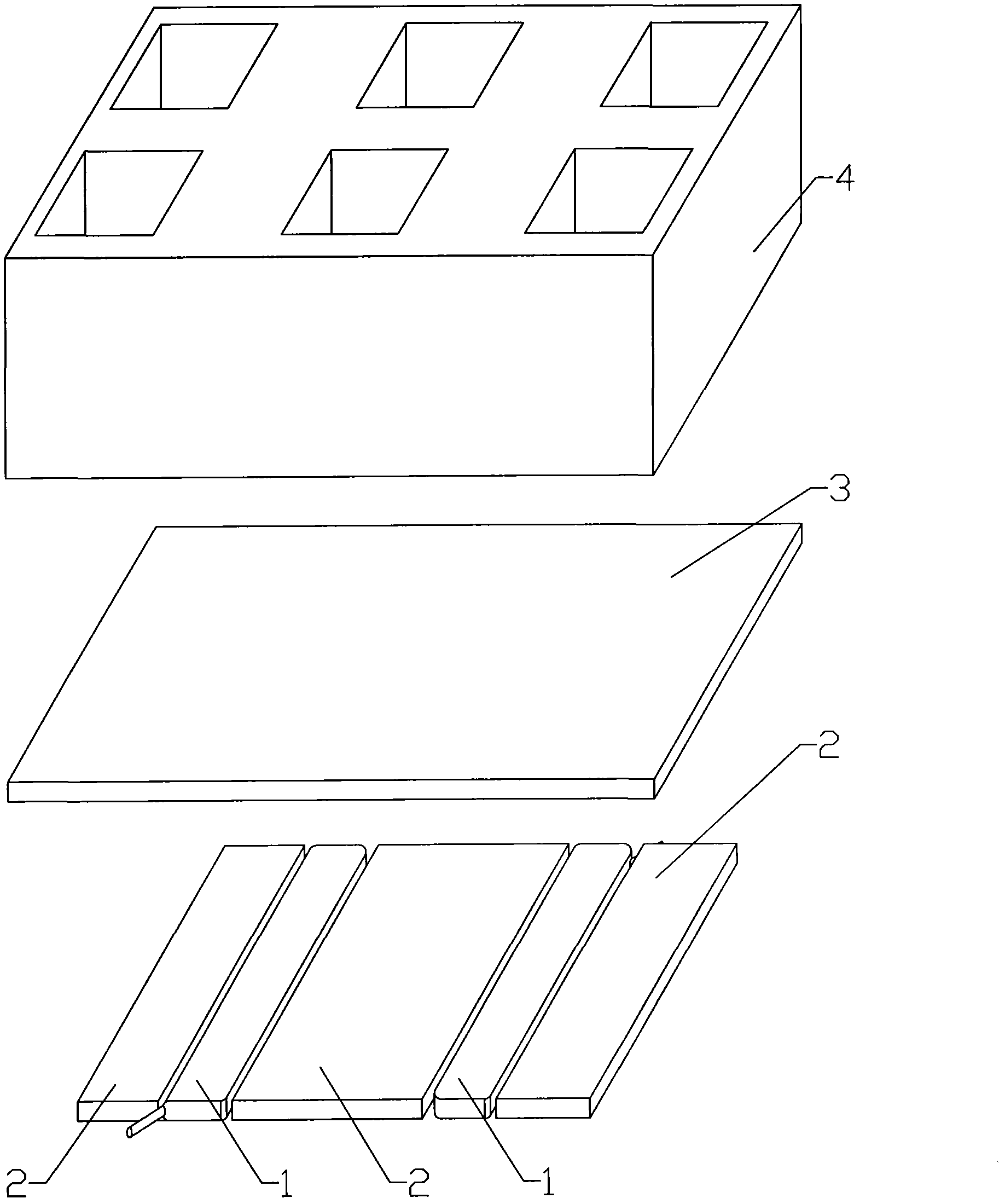

Method for jacking large-sized prefabricated parts

InactiveCN102502459ALow construction costShorten the construction periodLifting devicesEngineeringAir sacs

The invention discloses a method for jacking large-sized prefabricated parts, which is characterized by including: setting air sacs, erecting a jacking base, laying a bottom plate, prefabricating a part, jacking and removing the air sacs. The method has the advantages that building cost of a prefabricating site is reduced, load of the prefabricating site is small, jacking stability is high, service cost is low, safety is high, inflating speed is fast, and use is flexible and convenient. The flat air sacs are all set below the part and less prone to damage, specifications, layout, delivery and the like of the prefabricated parts are no longer limited by positions of air sac grooves or hydraulic jacks, labor and time are saved, the air sacs can directly pass through rolling air sacs from the bottom of the part after jacking the part, and no support cushion is needed.

Owner:钟爱民

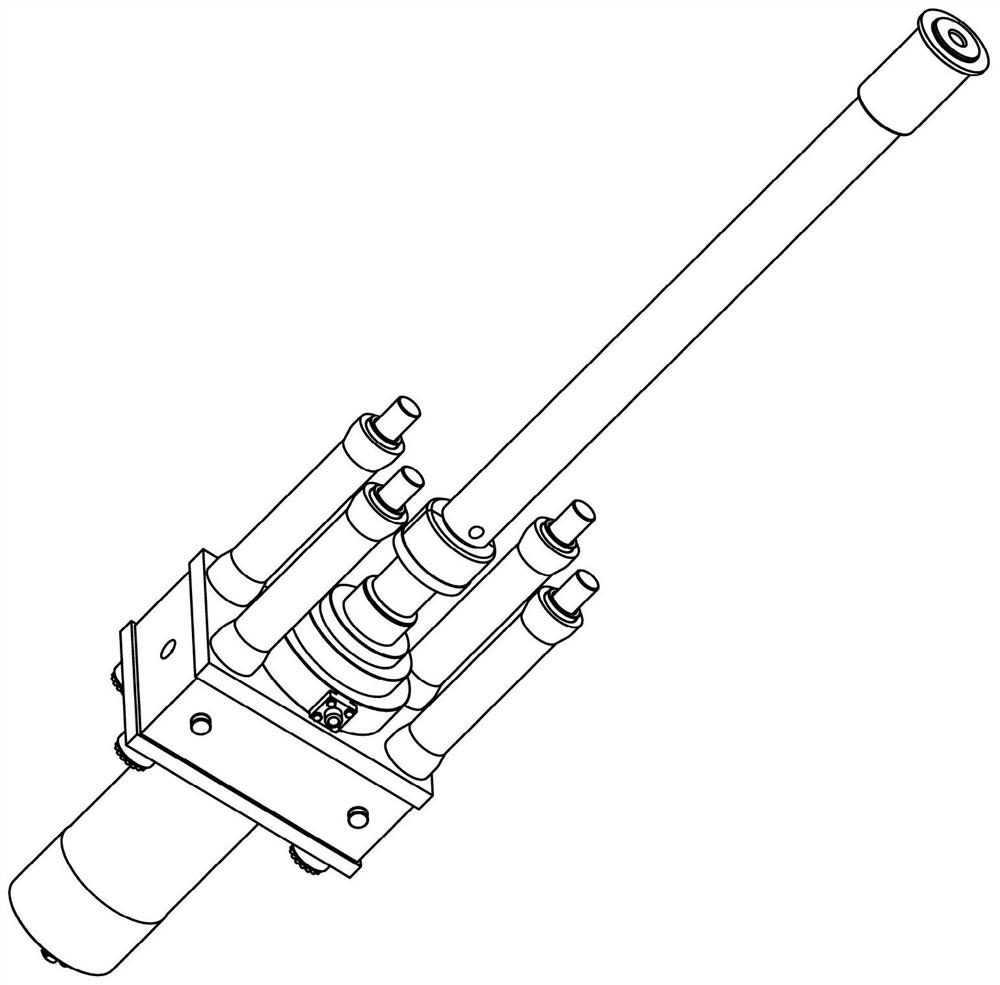

Electric thruster

The invention relates to an electric thrusting device which comprises a base seat. A screw is arranged on the base seat in a penetrating manner; the electric thrusting device also comprises a threaded rod and a nut which are meshed with each other; the front end of the threaded rod is a thrusting end; an external rotor permanent-magnetic servo motor is connected with the base seat; the nut is fixed on the a rotor of the external rotor permanent-magnetic servo motor; a limiting component which limits the rotation of the threaded rod and allows the parallel move of the threaded rod is arranged at the front part of the threaded rod. The electric thrusting device has the advantages of compact and convenient structure, high energy efficiency ratio, accurate control of die-locking travel and big jacking force.

Owner:UNION PLASTIC HANGZHOU MACHINERY

Method for jacking rectification of building

InactiveCN111411650AImprove the bearing capacity of single pileLarge jacking forceFoundation repairBulkheads/pilesRock boltArchitectural engineering

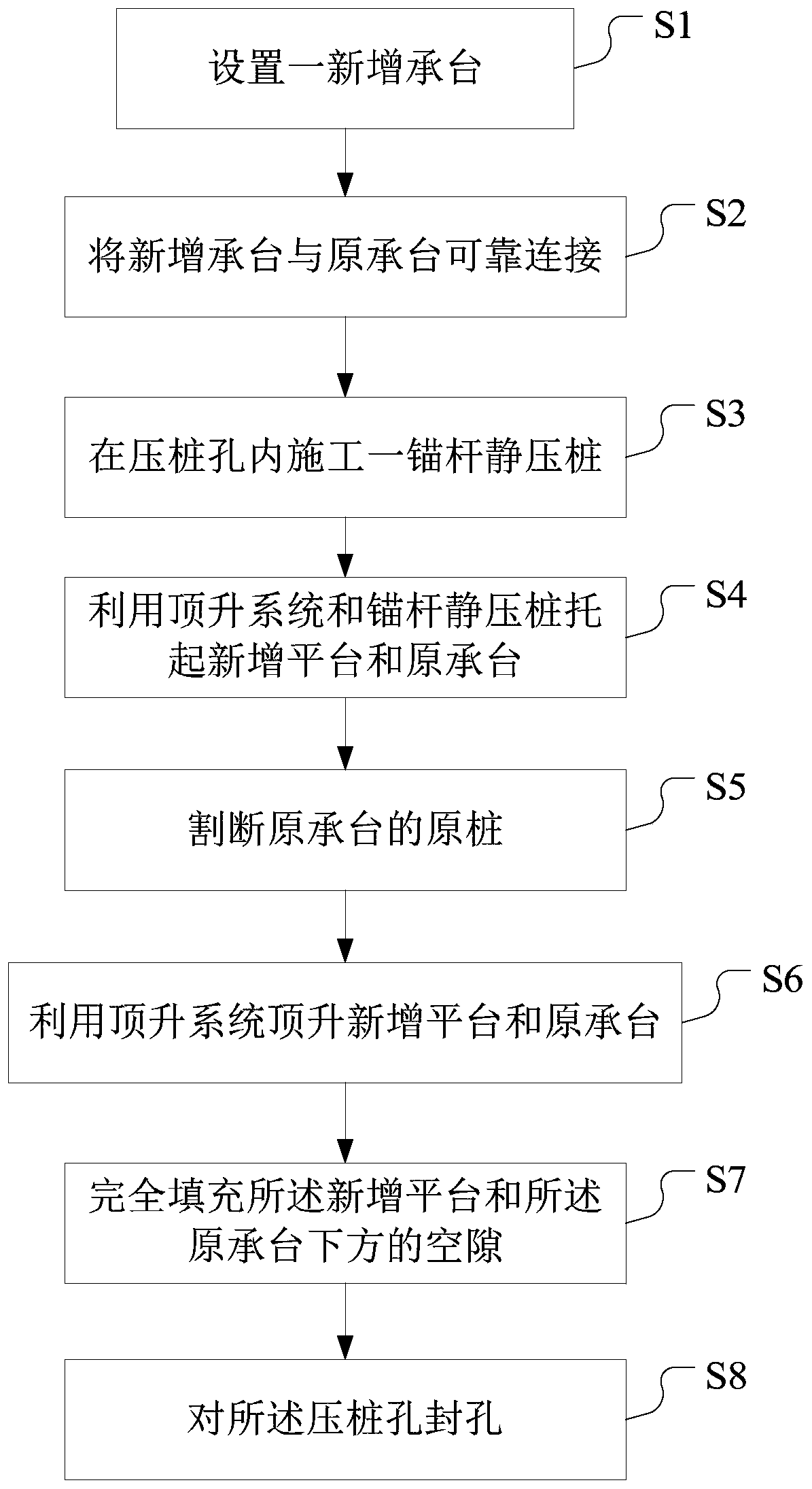

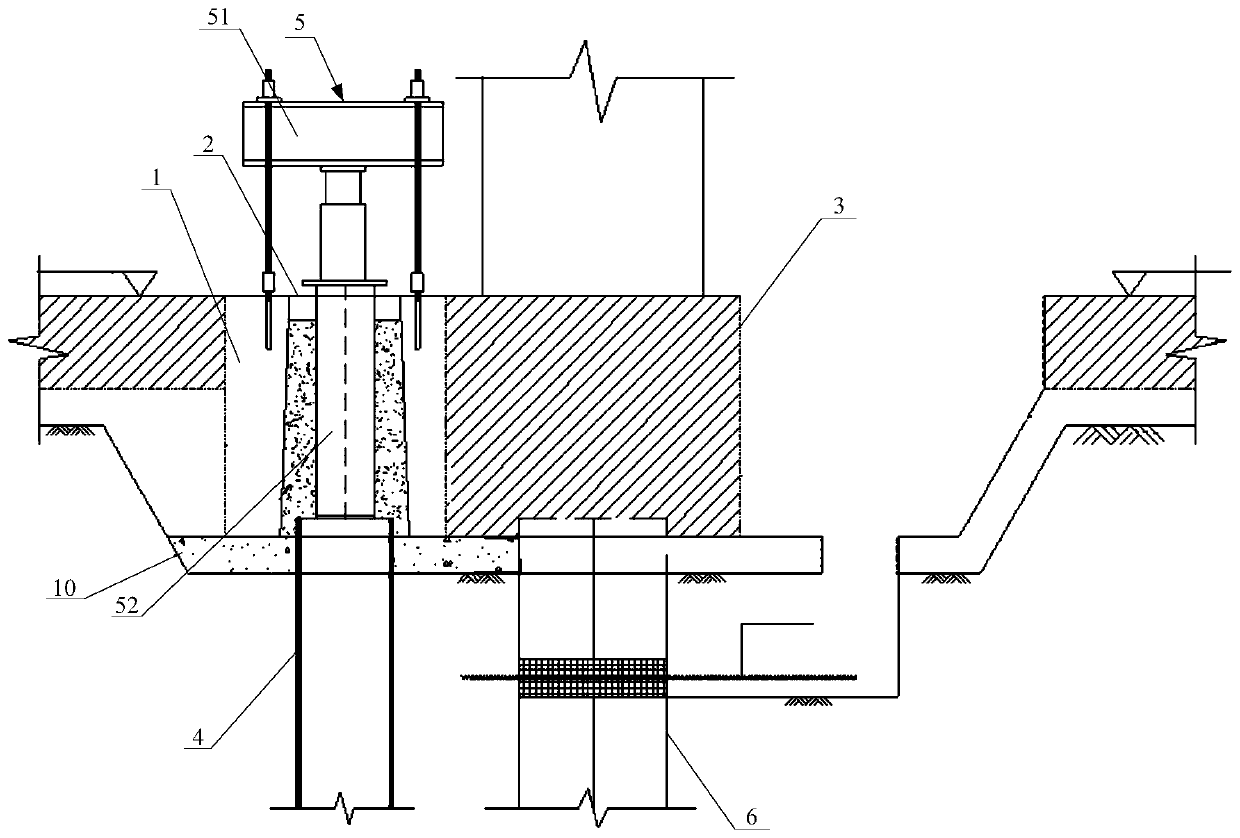

The invention provides a method for jacking rectification of a building. The method includes the following steps that S1, a newly added bearing platform is arranged, the newly added bearing platform reserves a pile pressing hole; S2, the newly added bearing platform is reliably connected with an original bearing platform; S3, an anchor rod static pressure pile is constructed in the pile pressing hole; S4, the newly added platform and the original bearing platform are supported by a jacking system and the anchor rod static pressure pile; S5, an original pile of the original bearing platform iscut off; S6, the newly added platform and the original bearing platform are jacked by the jacking system; S7, a gap below the newly added platform and the original bearing platform is fully filled; and S8, the pile pressing hole is sealed. According to the method for jacking rectification of the building, the damage to the building caused by jacking is reduced, damage to an original structure of the building is not required, and the safety is relatively high.

Owner:SHANGHAI CHANGKAI GEOTECHN ENG

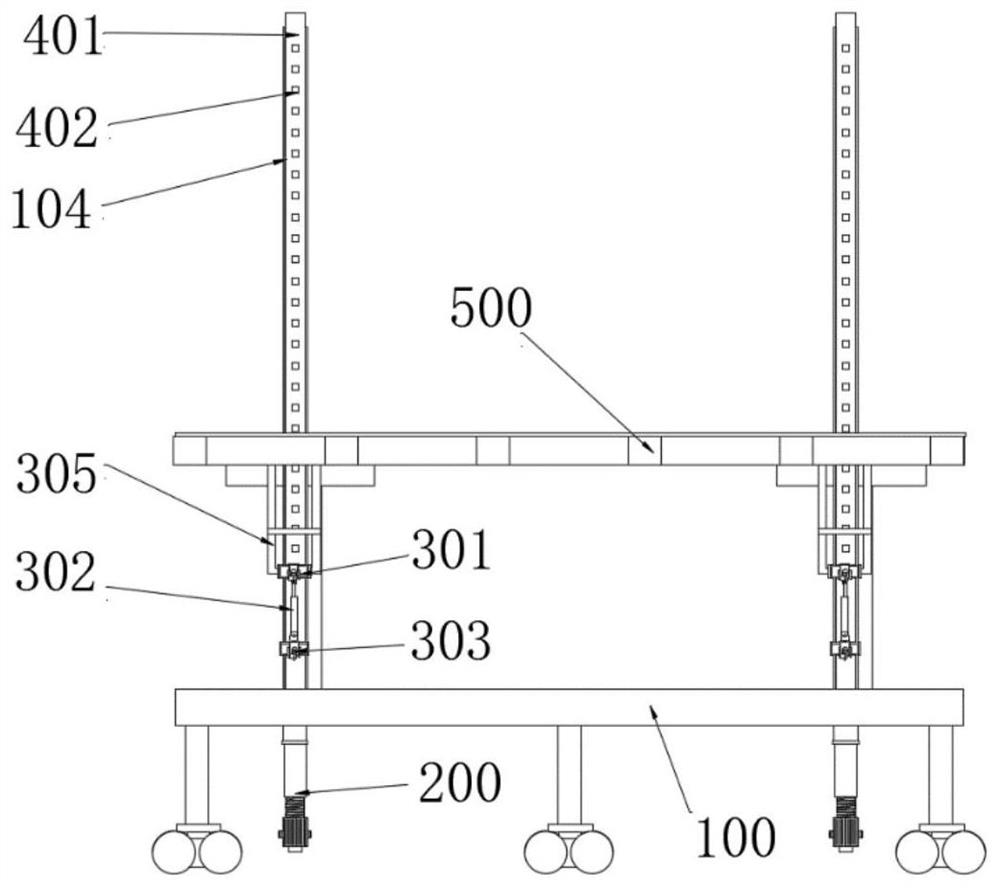

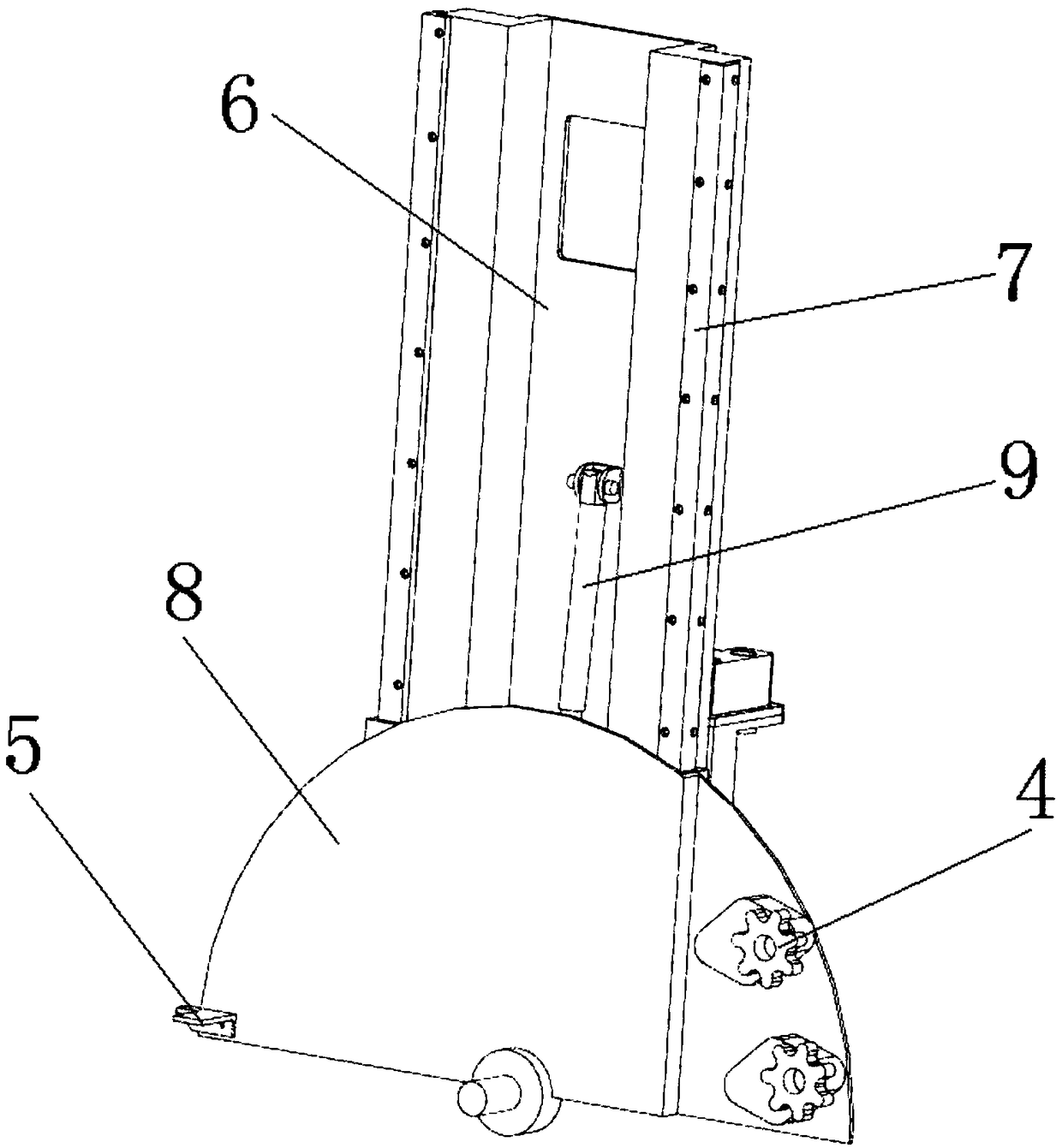

Prefabricated bridge structure climbing equipment and control method

InactiveCN111608088AImprove construction efficiencyRealize automatic controlBridge erection/assemblyGear wheelDrive motor

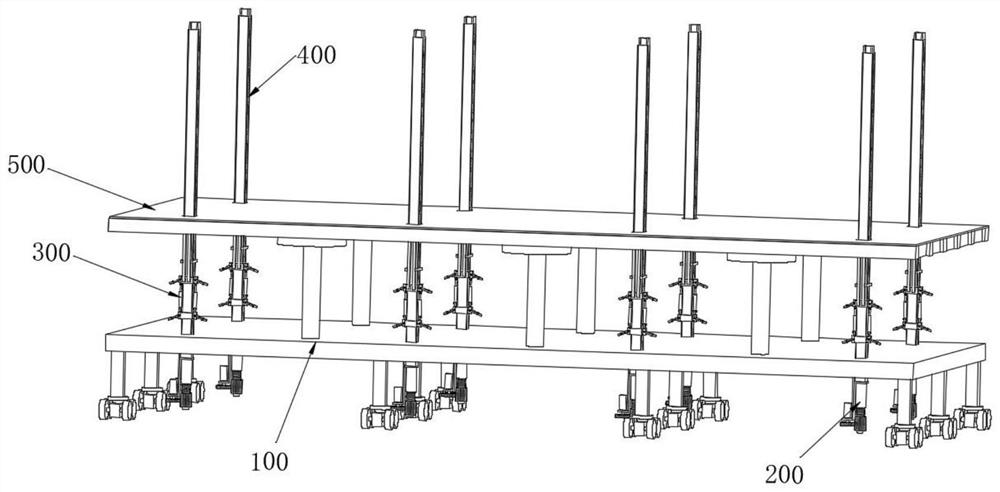

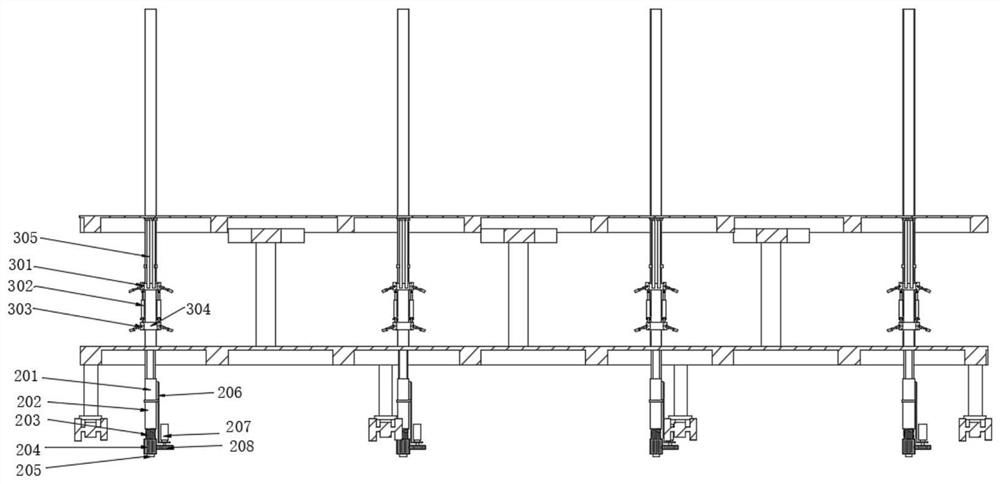

The invention provides prefabricated bridge structure climbing equipment and a control method, which belong to the technical field of building construction for solving the problem of synchronous pushing of prefabricated box girder units. The equipment comprises a bearing platform, a supporting steel column system, a hydraulic driving system and a pre-supporting adjusting system, wherein the supporting steel column system comprises a supporting steel column and a climbing boot clamping groove; the hydraulic driving system comprises a jacking oil cylinder assembly, a rectangular frame and a supporting rod; the pre-supporting adjusting system comprises a connecting component, a threaded sleeve, a rotating screw and a rotating gear which are sequentially arranged from top to bottom and are inrigid contact; and a pressure sensor is arranged below the rotating gear, and under the driving action of a driving motor, the motor gear drives the rotating gear engaged with the motor gear to rotate, so that the rotating screw is driven to slowly rotate anticlockwise to extend out of the threaded sleeve. The jacking oil cylinder drives the supporting steel column to descend in a large stroke, the motor drives the pre-supporting system to achieve displacement precision adjustment, and finally standardization of the supporting state of the supporting steel column is achieved.

Owner:SHANGHAI CONSTRUCTION GROUP

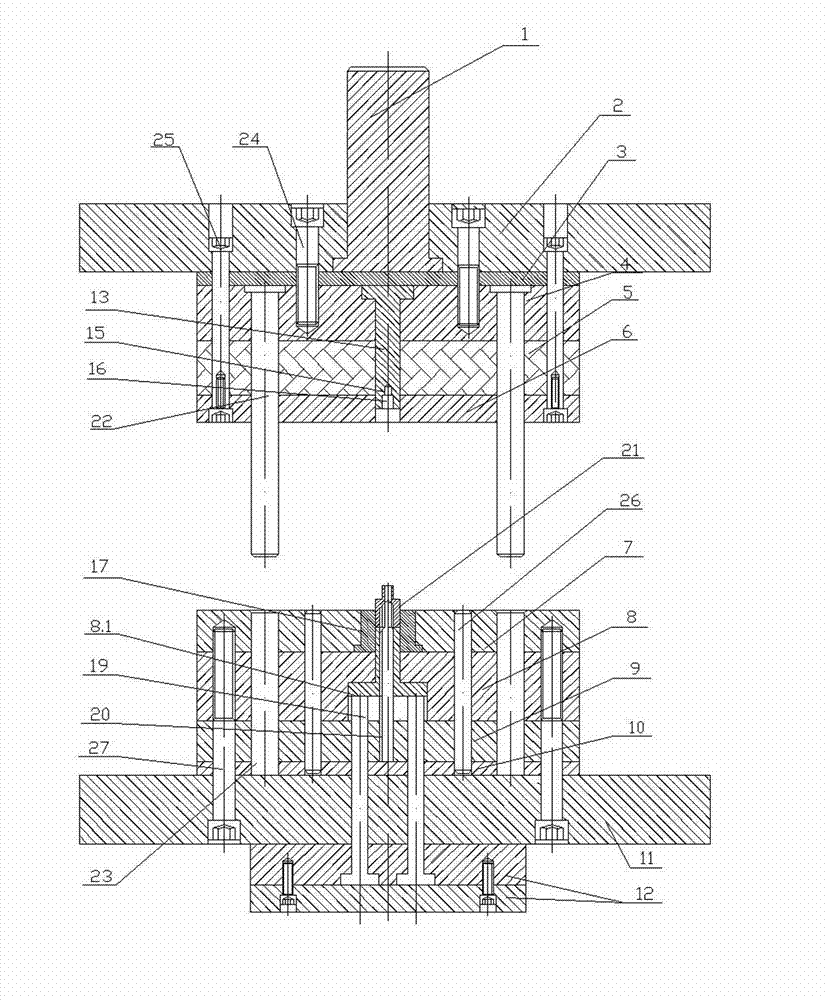

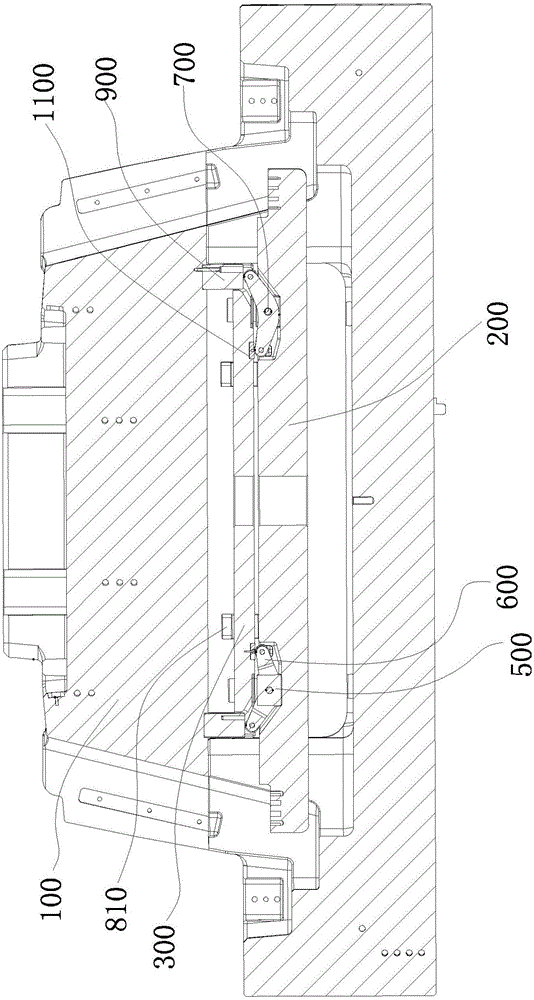

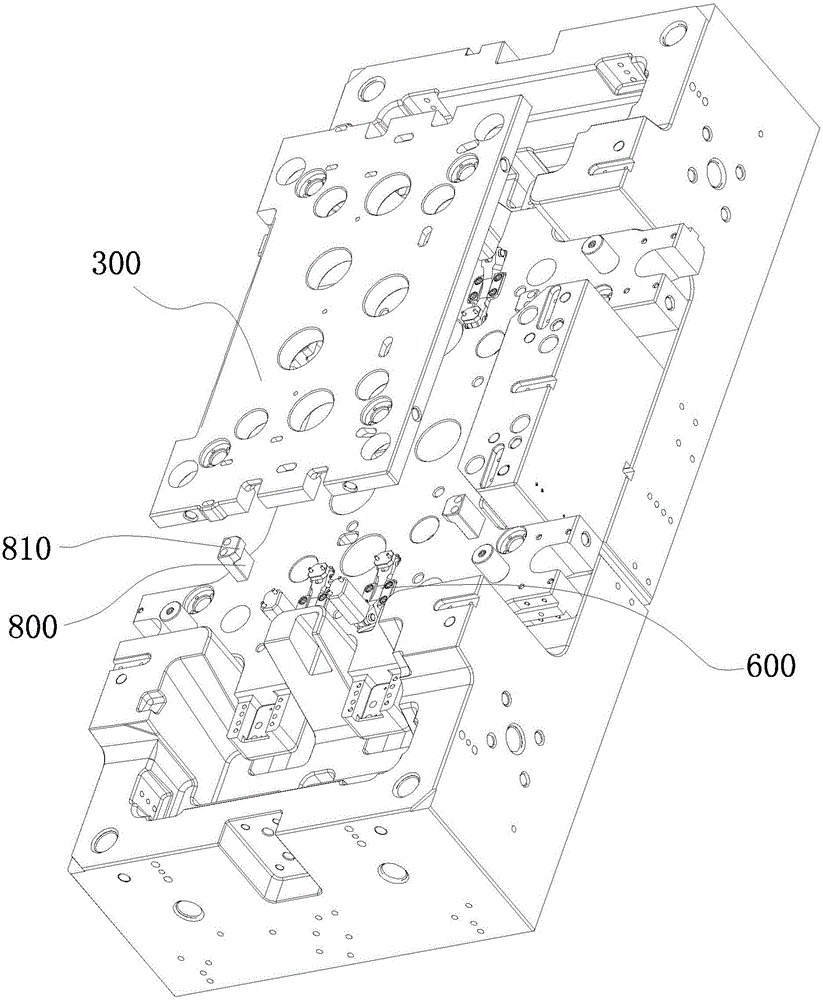

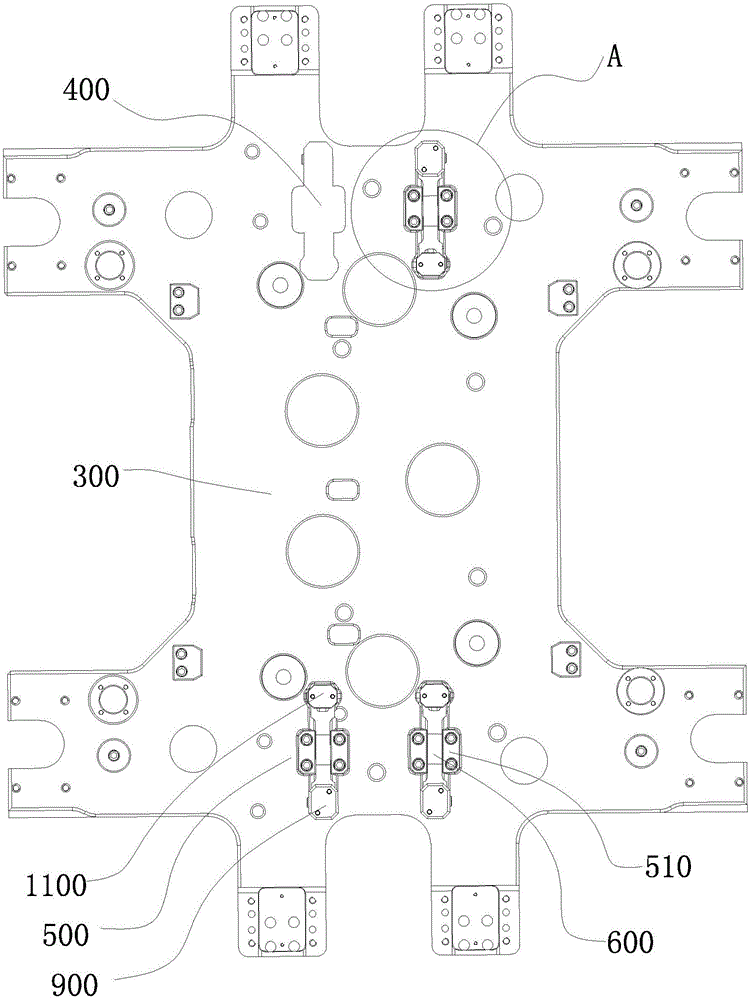

Major-minor multi-push injection mold pushing mechanism

The invention provides a main and auxiliary multi-top injection molding top mold mechanism, which includes a movable template, an ejection cylinder, a support rod, an ejector plate, and an ejector rod, and the ejector plate is connected with an ejector rod passing through the movable template , characterized in that: the movable template is provided with ribs, the ribs are parallel to the main body of the movable template, the ejector plate is located between the ribs and the main body of the movable template, the support rod passes through the ejector plate, The two ends are fixedly connected to the rib plate and the main body of the movable formwork respectively. The ejection cylinder includes a main ejection cylinder and an auxiliary ejection cylinder. The main ejection cylinder is directly connected to the rib plate, and its piston rod is connected to the ejector plate. connected, the auxiliary ejector cylinder is installed on the main body of the movable template, and its piston rod is also connected with the ejector plate. The ejector mold mechanism has sufficient strength and rigidity, and the ejection force is large and uniform, so that the force on the mold is evenly balanced, which can prolong the service life of the mold and effectively improve production efficiency and product qualification rate.

Owner:广州一道注塑机械股份有限公司

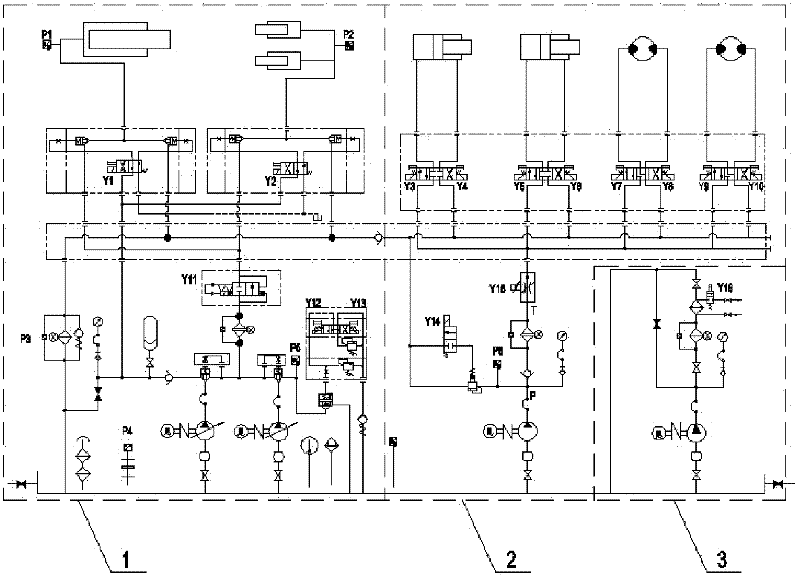

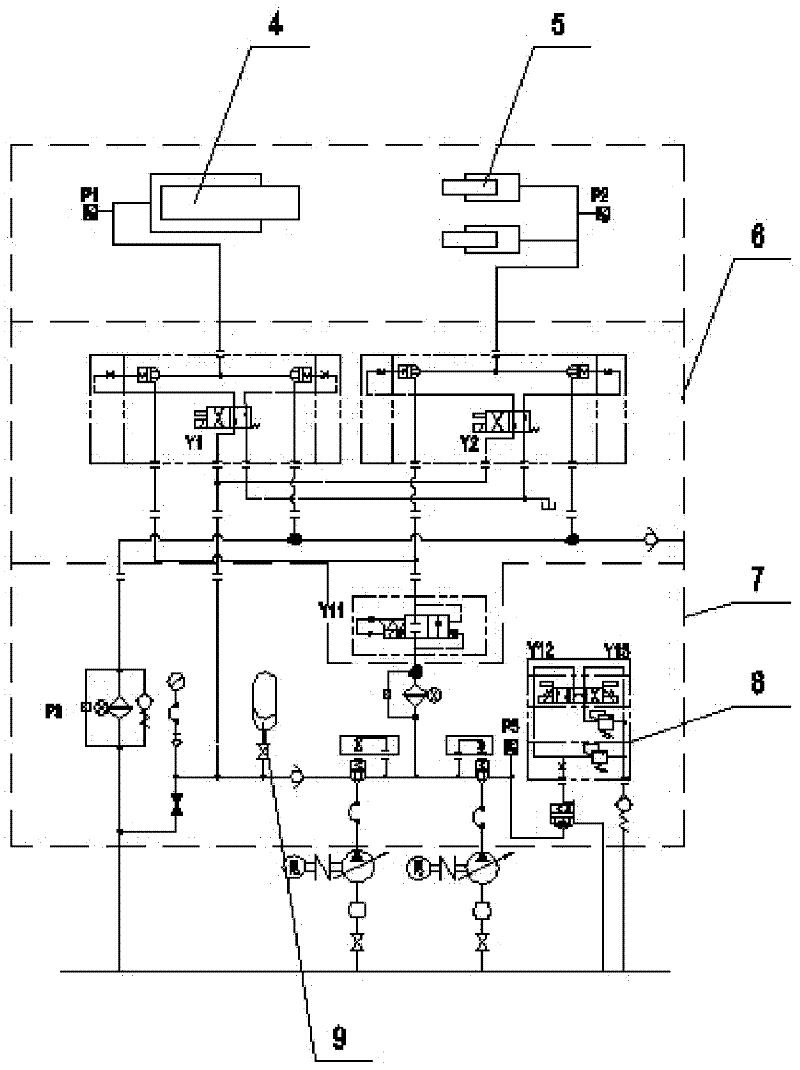

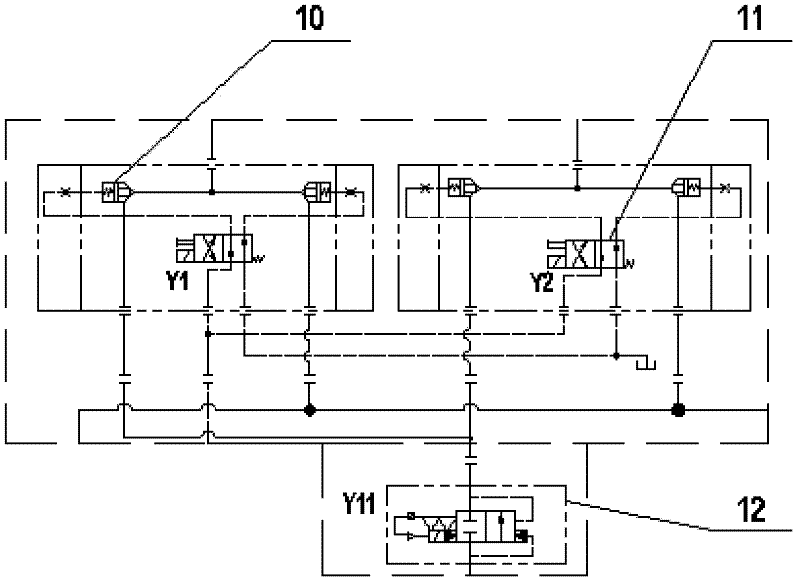

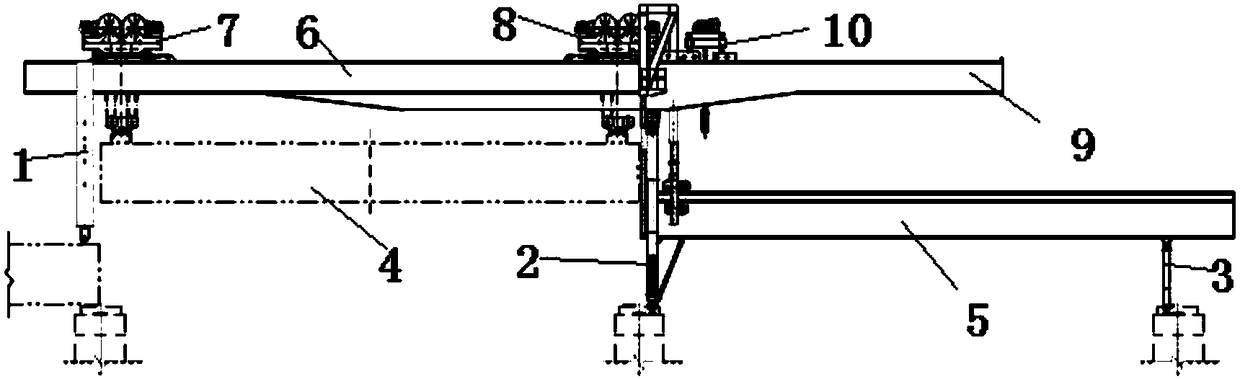

Hydraulic ejecting machine and working principle thereof

ActiveCN102580620AReduce labor intensityLower working temperatureServomotorsFeed devicesWorking temperatureTitanium

The invention discloses a hydraulic ejecting machine and a working principle thereof. The hydraulic system of the hydraulic ejecting machine comprises an ejection returning system (1), a position adjusting system (2) and a cooling system (3), wherein the ejection returning system (1) comprises an ejection cylinder (4), a returning cylinder (5), a main reversing valve group (6) and a main pressure regulating valve group (7); the position adjusting system (2) comprises a position cylinder (13), a lengthways cylinder (14), a lifting motor I (15), a lifting motor II (16) and a regulating valve group (17). The hydraulic ejecting machine and the working principle thereof, disclosed by the invention, has the advantages that: titanium products can be separated from a reactor, and great ejecting force and simple oil paths are realized as the hydraulic principle is utilized; labor intensity of operators is lightened greatly and production period of products is speeded up as the position adjusting system adjusts the position of a large-scale reactor (tank); and working temperature of the hydraulic system is reduced and working safety and reliability of the hydraulic system are improved as the cooling system is used.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

Bridge girder erection machine

InactiveCN108316159APrevent force asymmetryGuarantee safe and reliableBridge erection/assemblyEngineeringMechanical engineering

The invention discloses a bridge girder erection machine. A rear supporting leg, a front supporting leg and an auxiliary supporting leg are raised by adopting a double oil cylinder supporting assemblyrespectively, and correction assemblies are arranged on the rear supporting leg, the front supporting leg and the auxiliary supporting leg respectively; the corrosion assemblies are used for being responsible for monitoring synchronous balance movement when the double oil cylinder supporting and raising assemblies are raised so that asymmetrical and unbalanced raising is prevented when the doubleoil cylinder supporting and raising assemblies are raised. According to the bridge girder erection machine disclosed by the invention, the supporting legs are raised by adopting double oil cylinders,the raising force is large, the erection of relatively heavy bridges can be realized, the correction assemblies are arranged on the double oil cylinder supporting assemblies, synchronous raising of main girders or nose girders during raising can be guaranteed, the balance and stress uniformity during the raising process are guaranteed, the stress asymmetry of the bridge girder erection machine during girder erection is prevented, the safety reliability of the bridge girder erection machine is guaranteed, and the bridge girder erection machine plays preferable monitoring and safety guarantee roles for the operation of large-scale bridge girder erection machines.

Owner:王治民

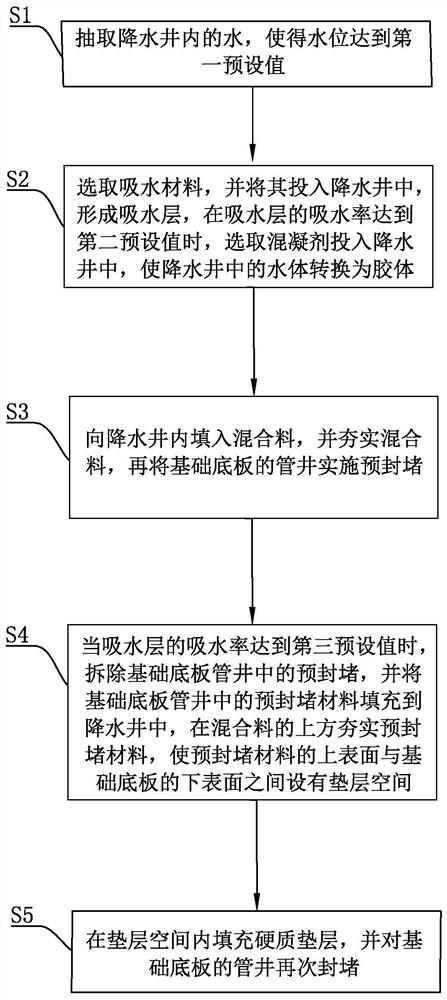

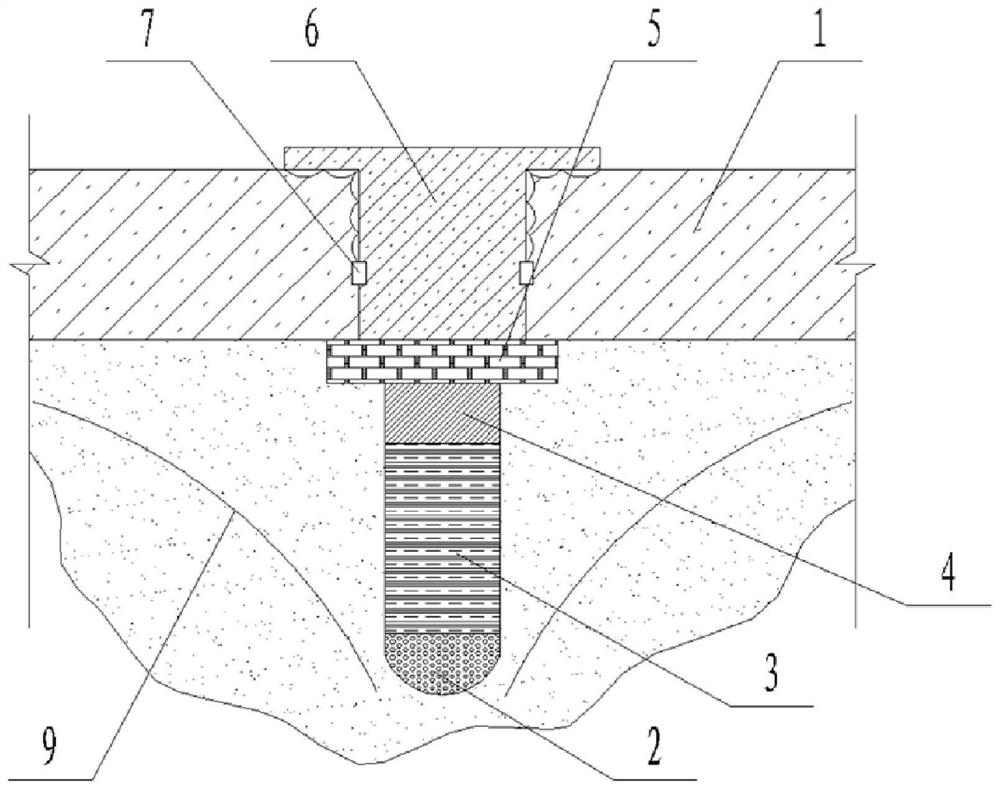

Precipitation well blocking method

The invention relates to the technical field of engineering construction, solves the problem that in the prior art, a precipitation well is not prone to being blocked, and particularly discloses a precipitation well blocking method. Multiple pieces of water absorption resin are put into the precipitation well to form a water absorption layer, and water in the precipitation well is converted into colloid through a coagulant; the characteristics of the colloid are utilized to settle sand grains and broken stones in the water, so that the quicksand phenomenon is reduced; when the colloid is adsorbed on the inner wall of the precipitation well, some sand grains, broken stones and water absorption resin can be adsorbed on the inner wall, so that the quicksand phenomenon is further inhibited, and water seepage can be reduced; and a mixture and a pre-blocking material are added into the precipitation well in sequence and are tamped in sequence, so that the water absorption resin expands to the periphery, soil on the side edge of the precipitation well is extruded and tamped, the density of the precipitation well is improved, the water permeability is reduced, the mixture is prevented from losing efficacy, and a relatively dry environment can be provided for final blocking.

Owner:浙江二十冶建设有限公司 +1

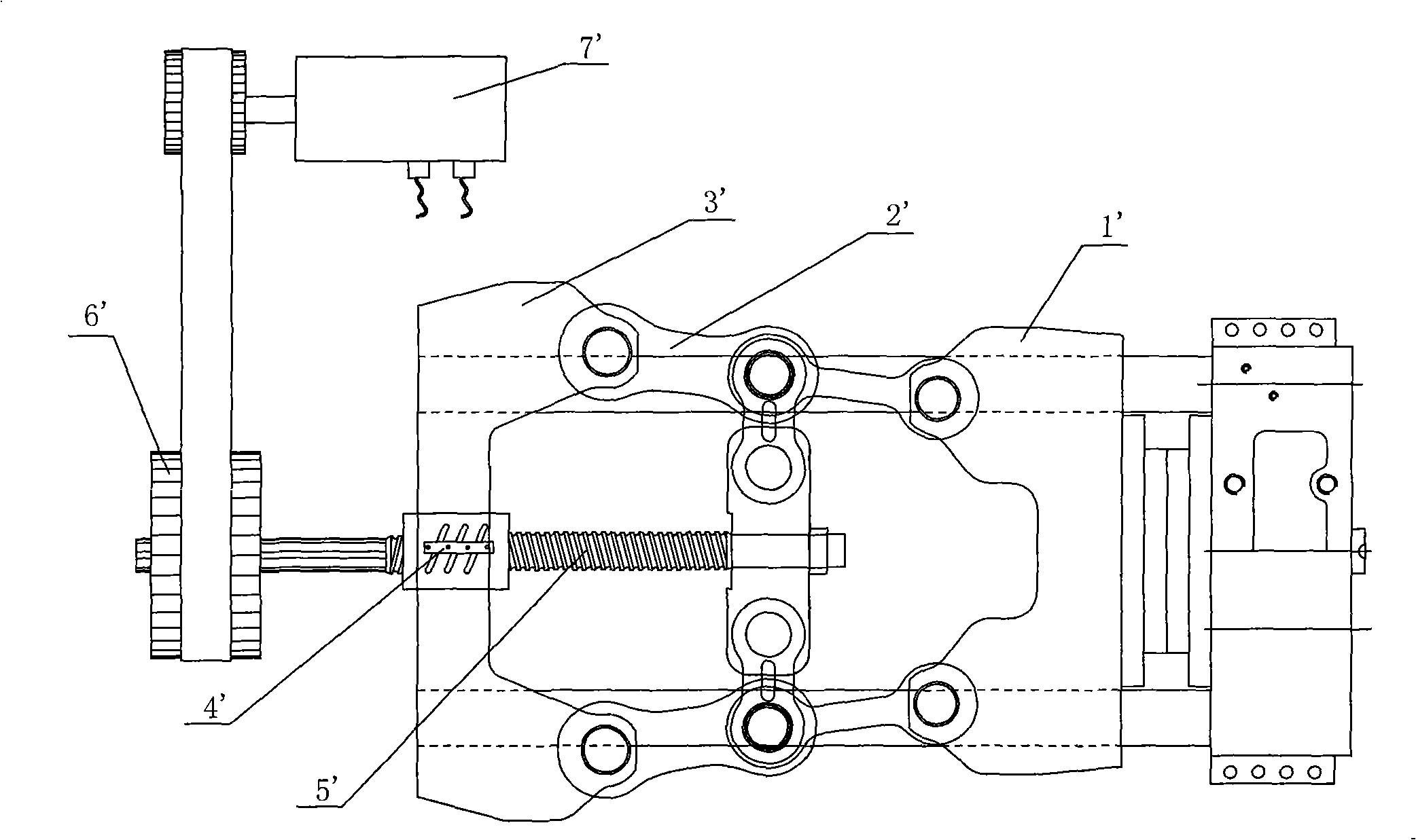

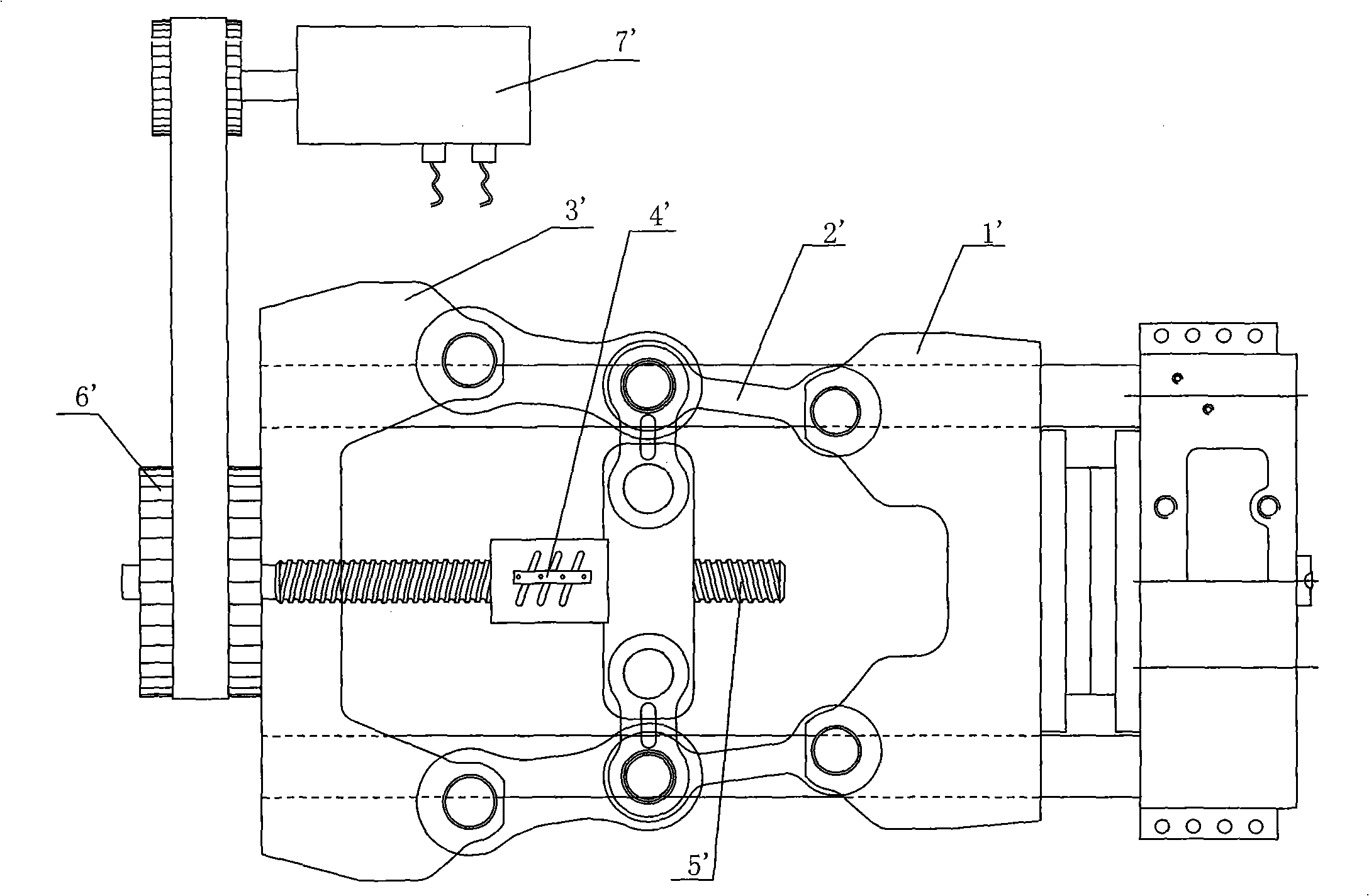

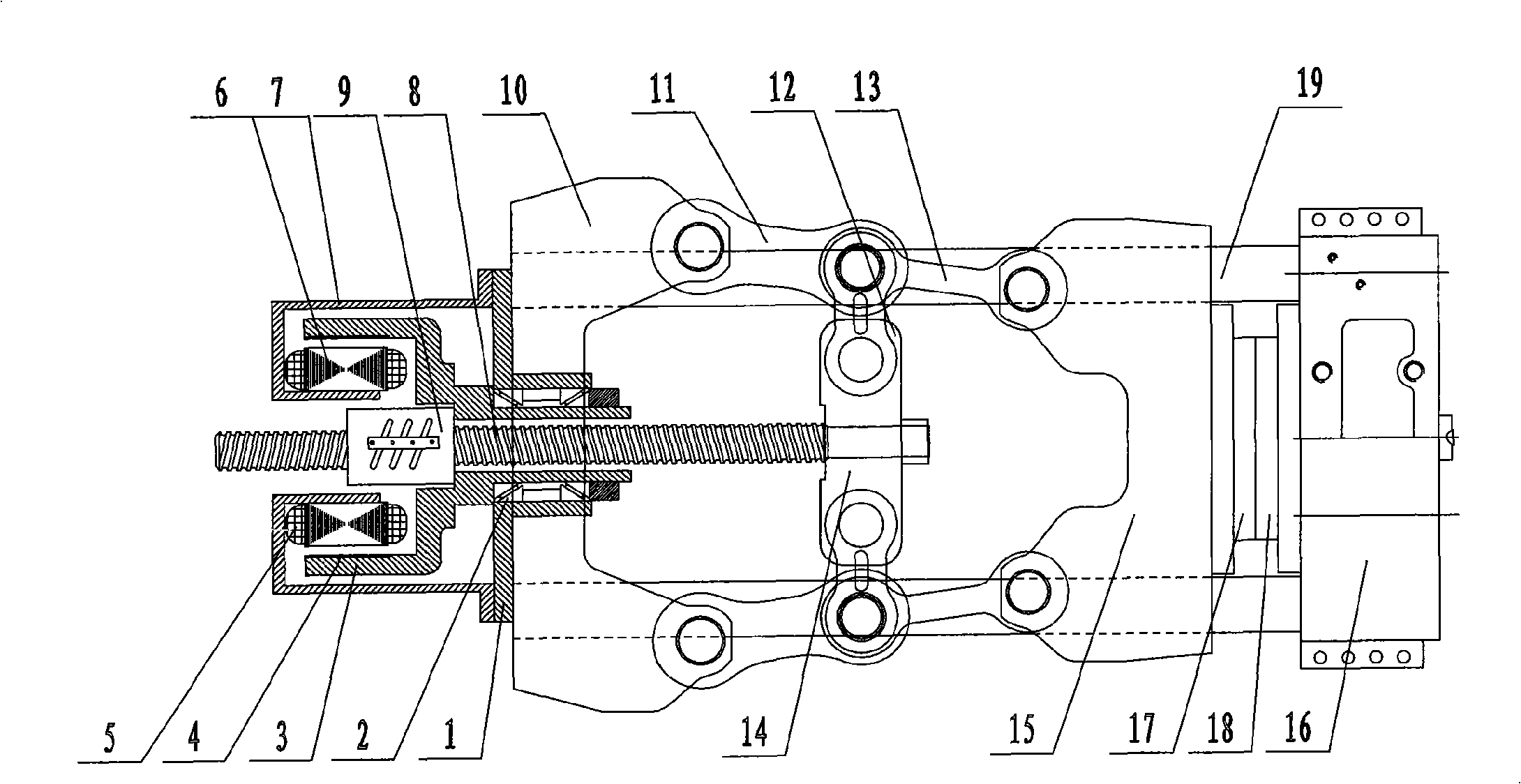

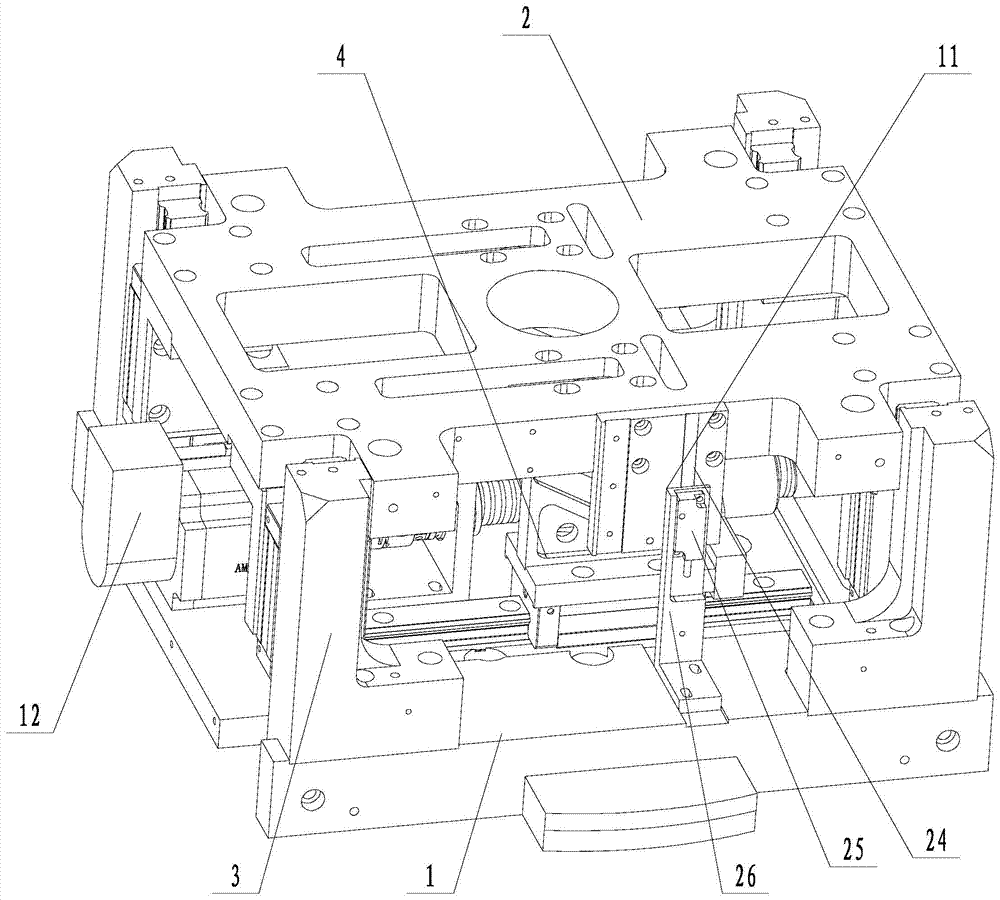

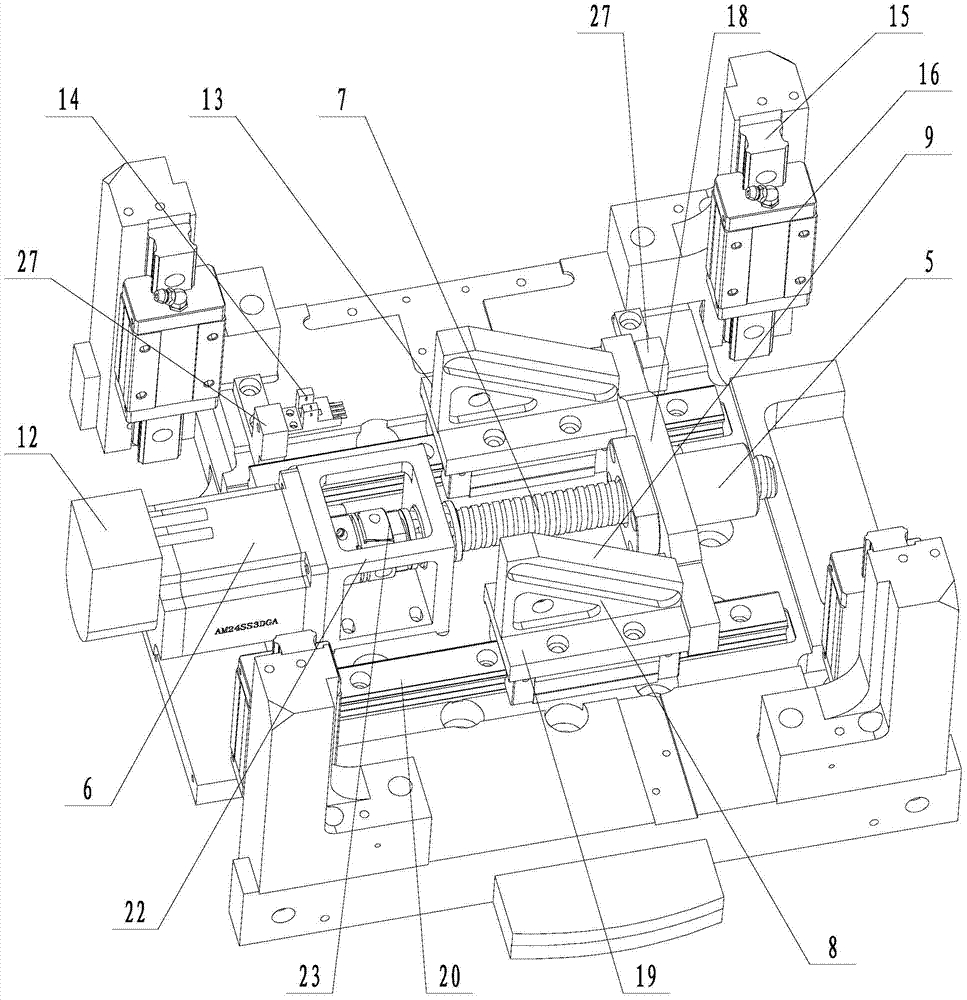

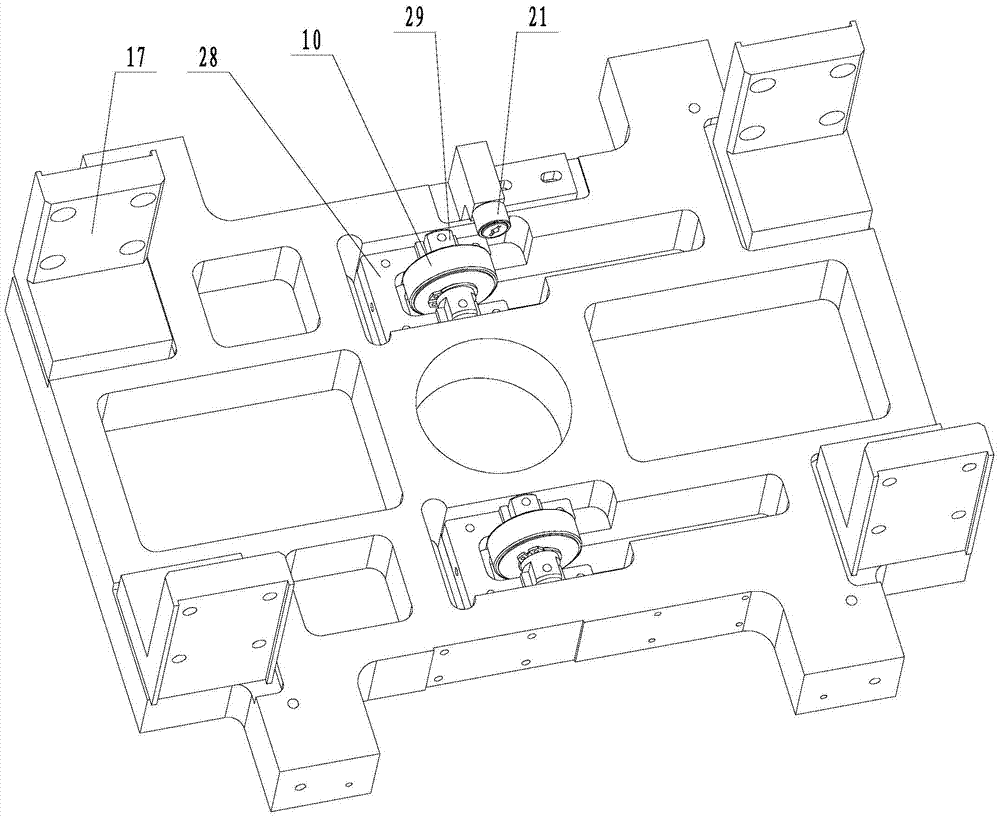

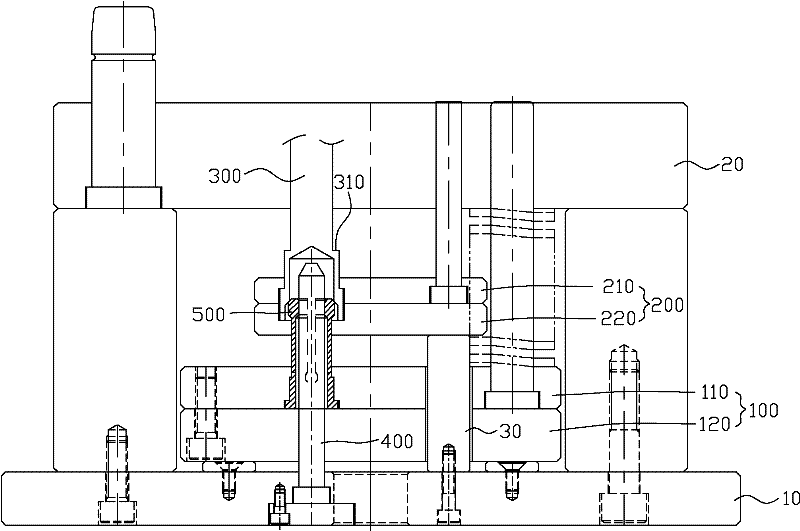

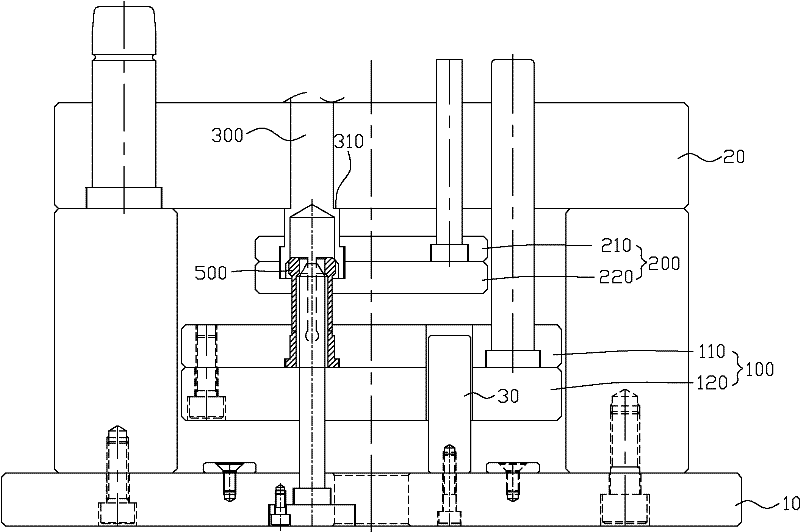

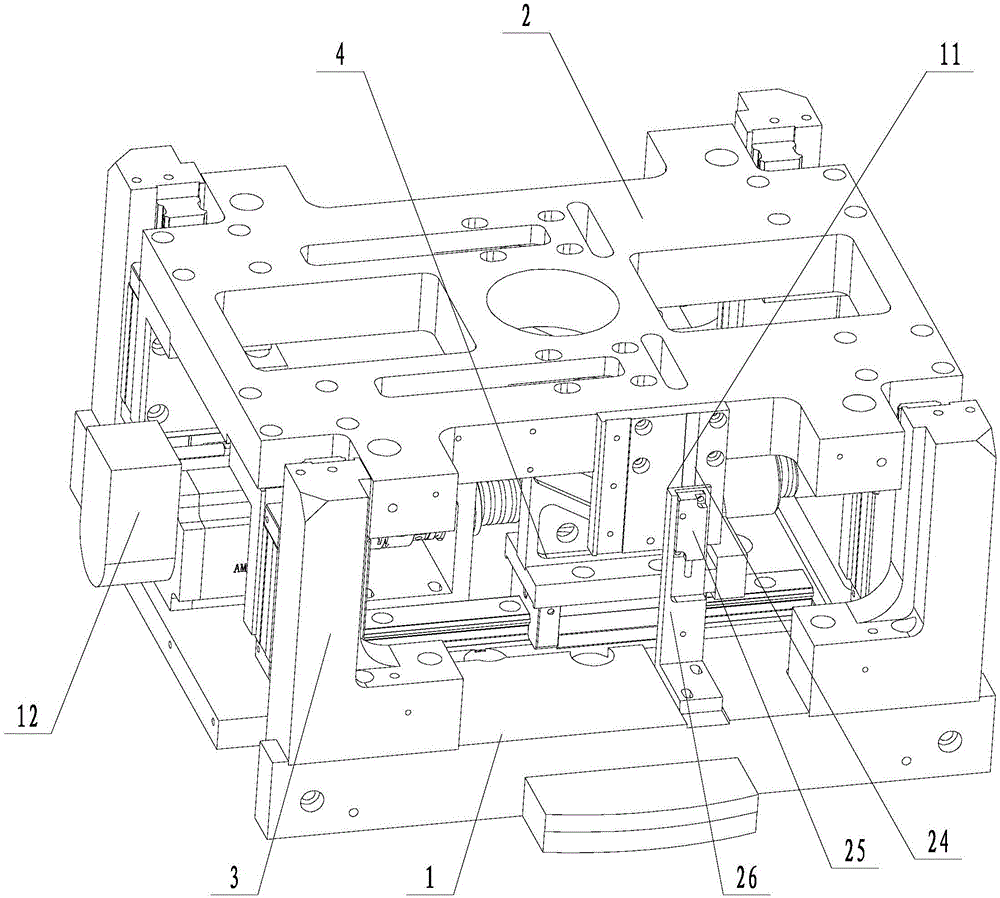

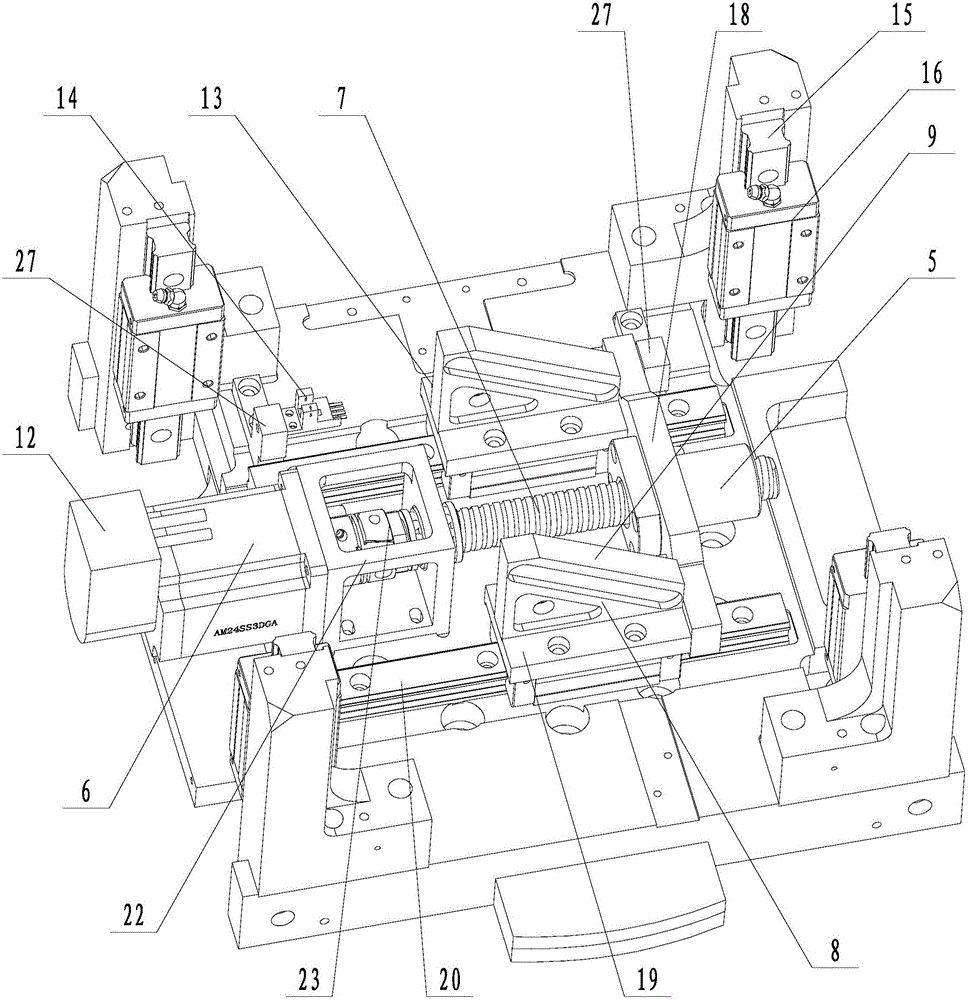

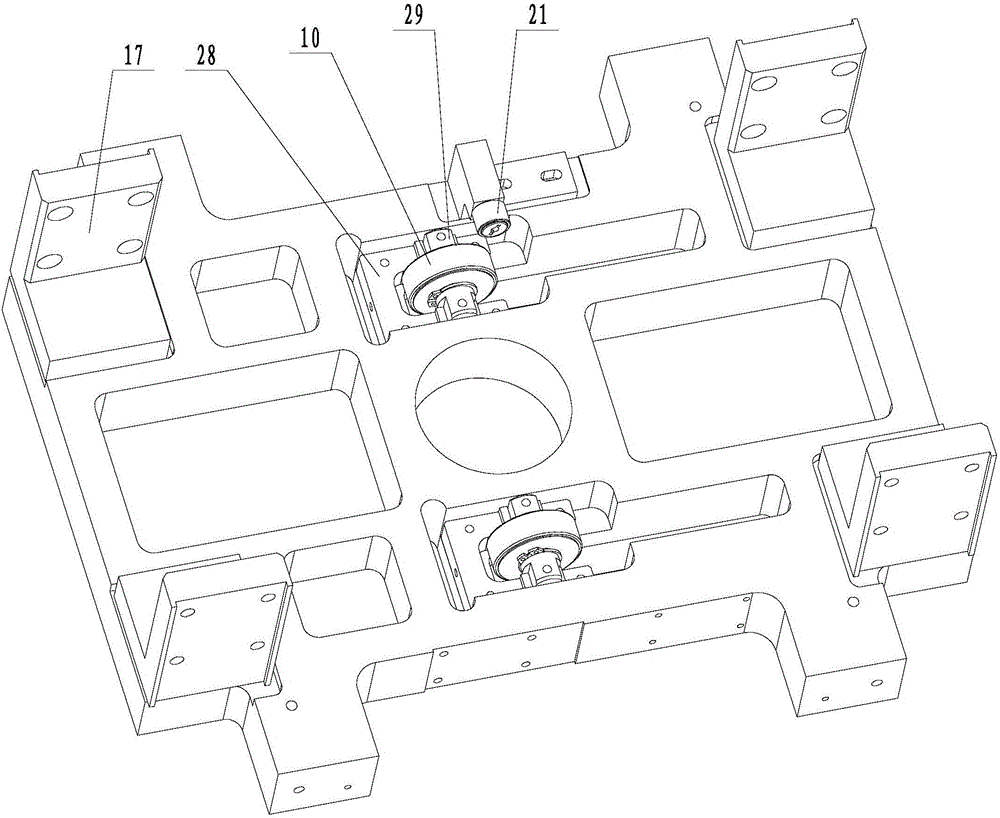

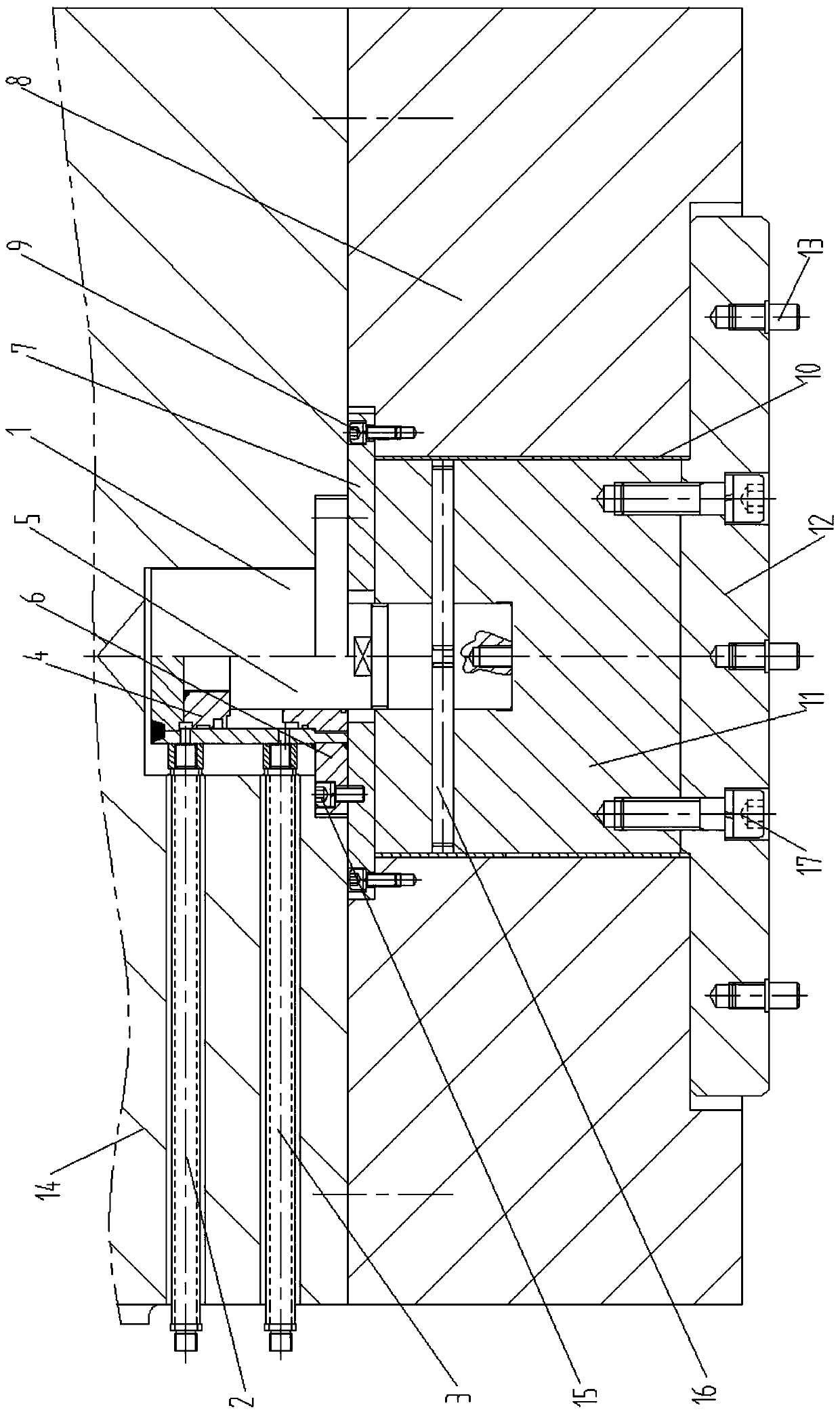

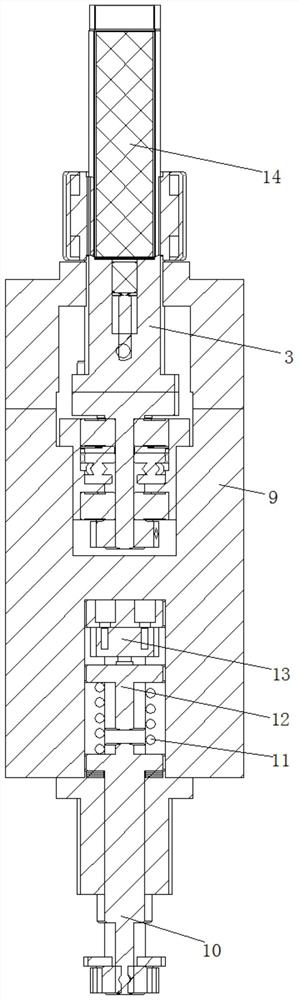

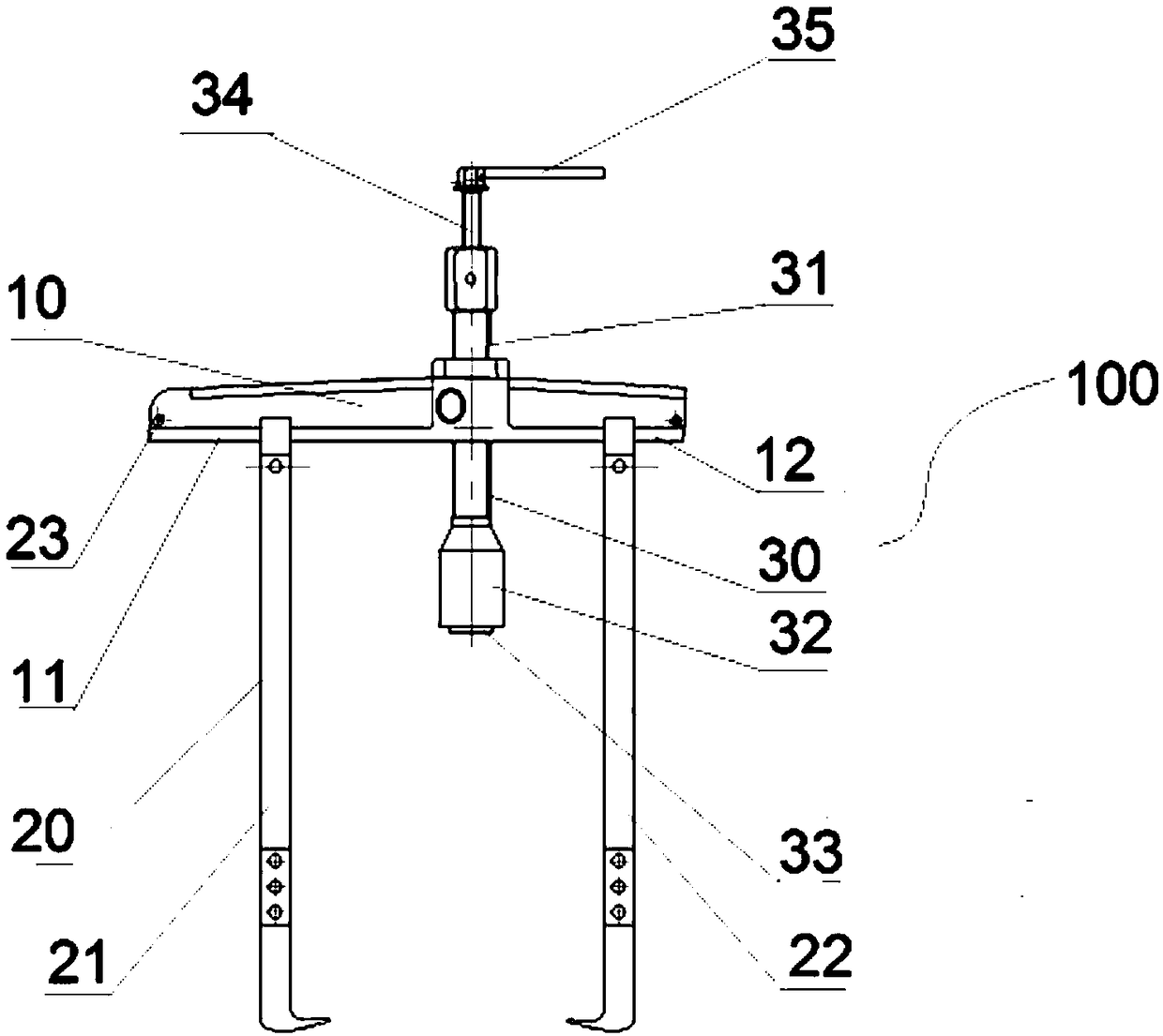

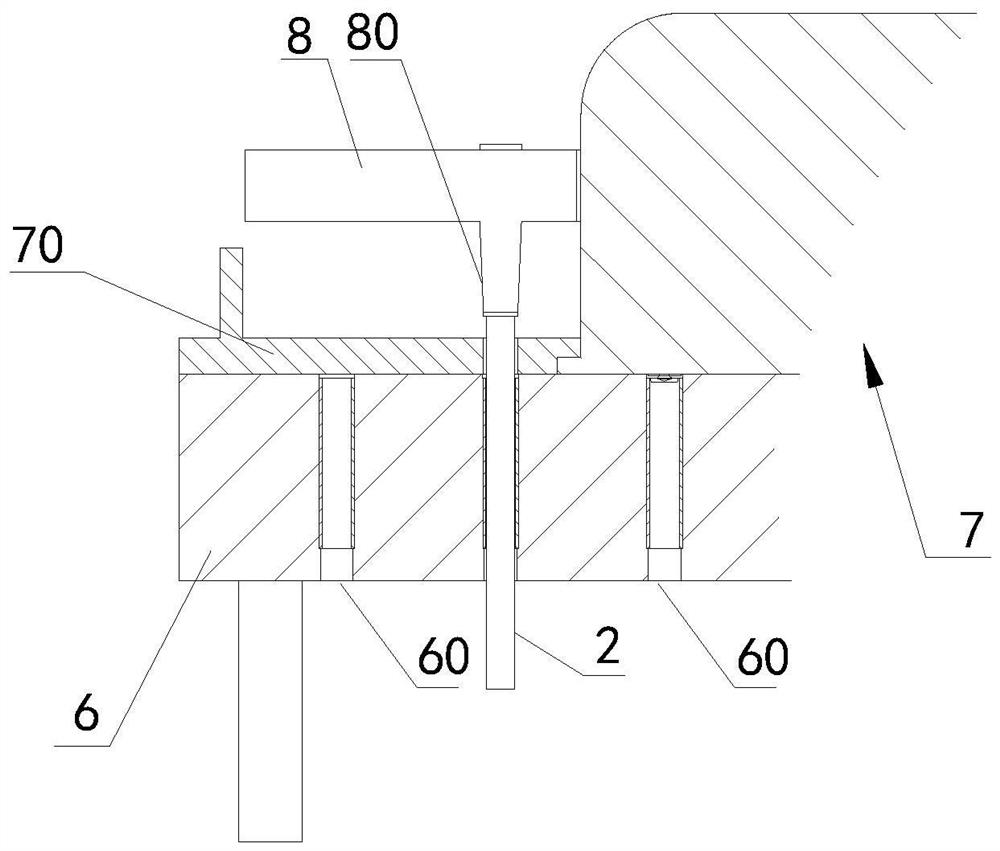

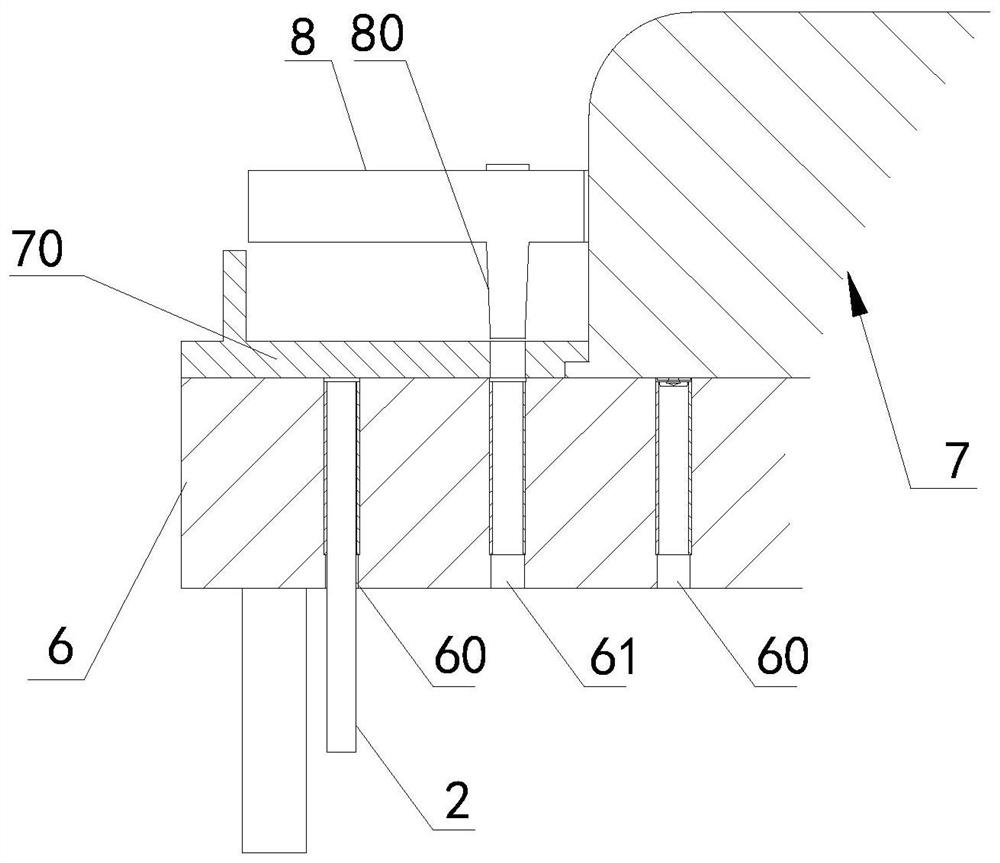

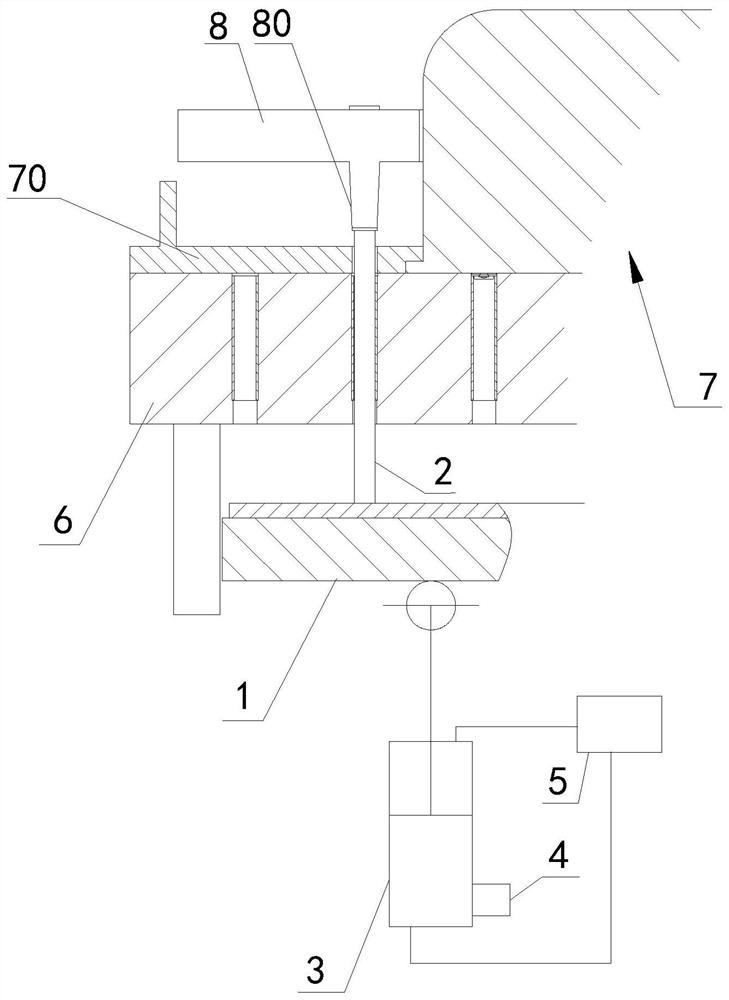

A tilting block lifting mechanism for wafer testing

ActiveCN105047575BBig jacking forceEasy to liftSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGratingDrive motor

The invention discloses an oblique block elevating mechanism for a wafer test, and aims to solve defects that according to the conventional elevating mechanism for the wafer test, the lifting force is small, the lifting stability is poor, the precision is low, the structure is complex, and the manufacturing cost is high. The oblique block elevating mechanism comprises a base and a supporting plate, a plurality of elevating slide rail seats are fixedly connected on the base, the supporting plate is connected on the elevating slide rail seats in an elevating manner, the base is connected with a supporting seat in a sliding manner, the supporting seat is arranged below the supporting plate, the supporting seat is fixedly connected with a screw rod nut, the base is provided with a driving motor, an output shaft of the driving motor is connected with a screw rod in a transmission manner, the screw rod is connected with the screw rod nut in a cooperation manner, the supporting seat is provided with oblique blocks, the upper end surfaces of the oblique blocks are inclined planes, the supporting plate is provided with rollers, the rollers are abutted against the upper end surfaces of the oblique blocks, a grating scale used for displacement measurement of the supporting plate is arranged between the supporting plate and the base, the driving motor is electrically connected with an encoder, and the grating scale is electrically connected with the encoder.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

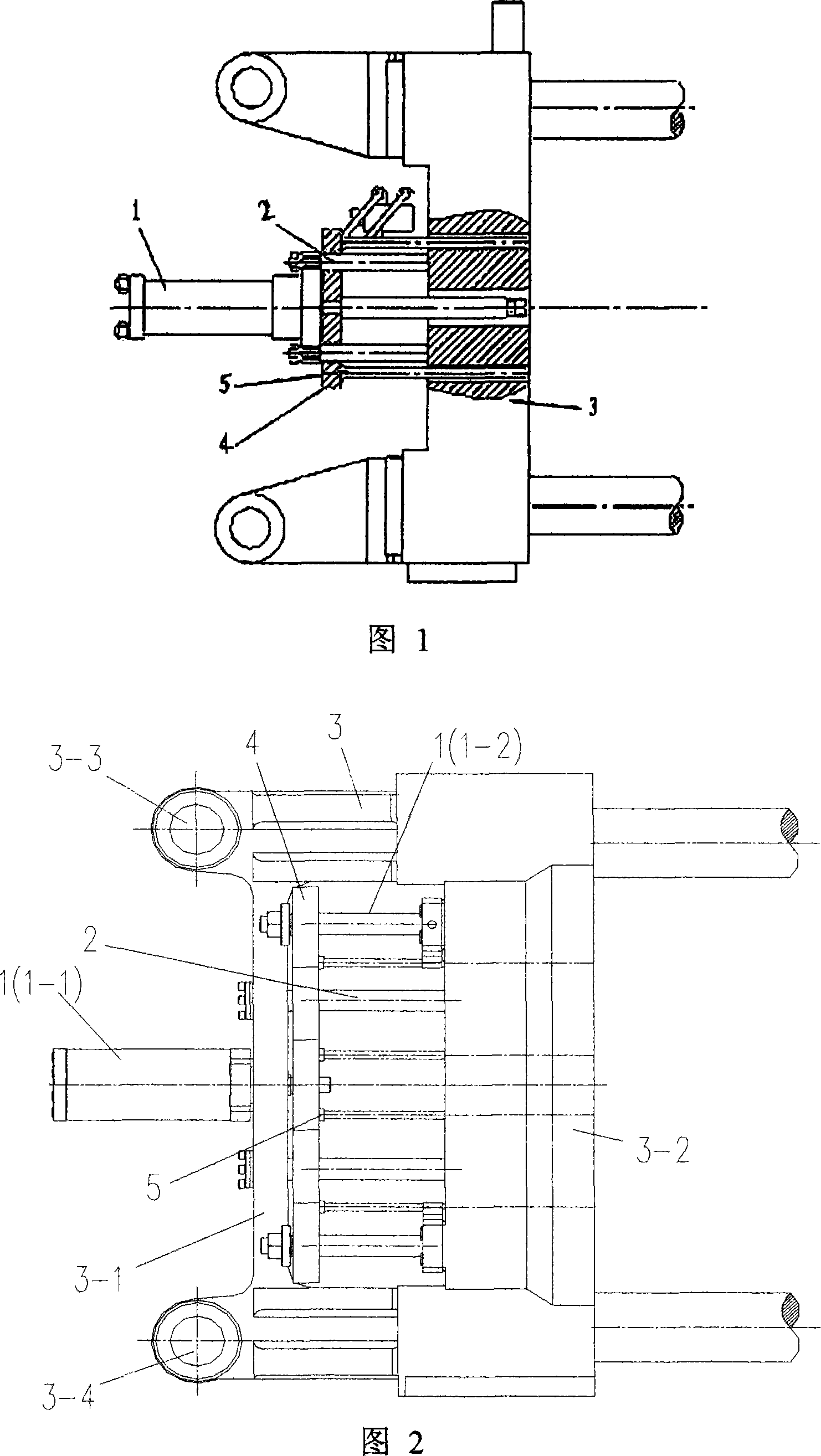

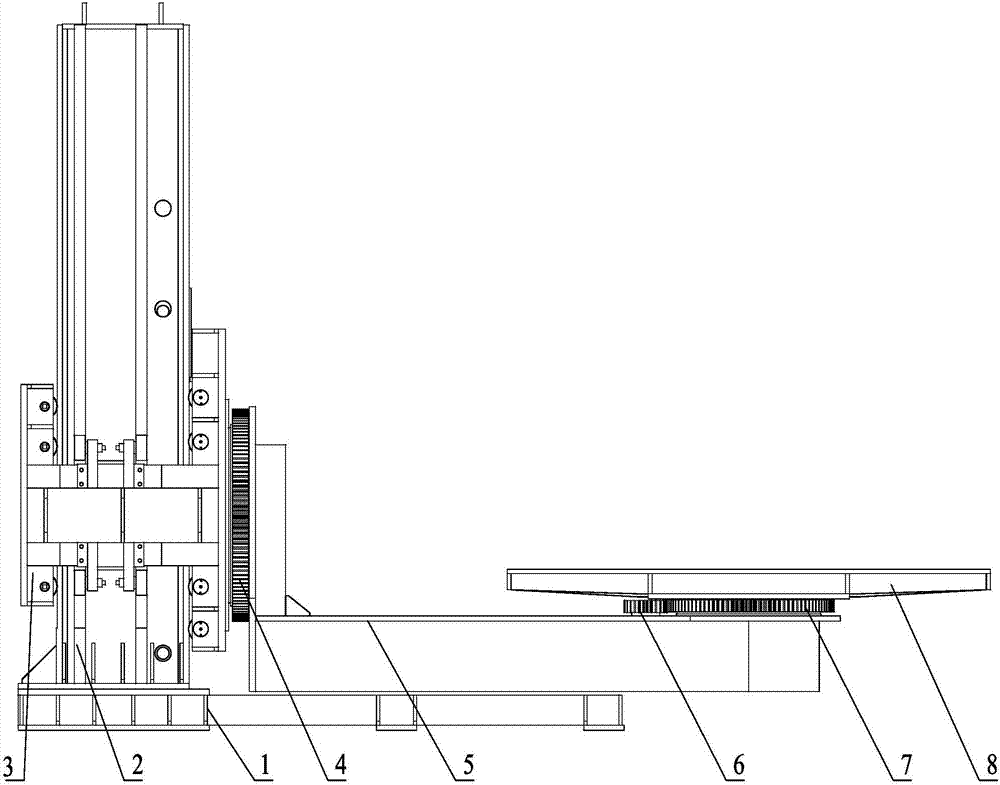

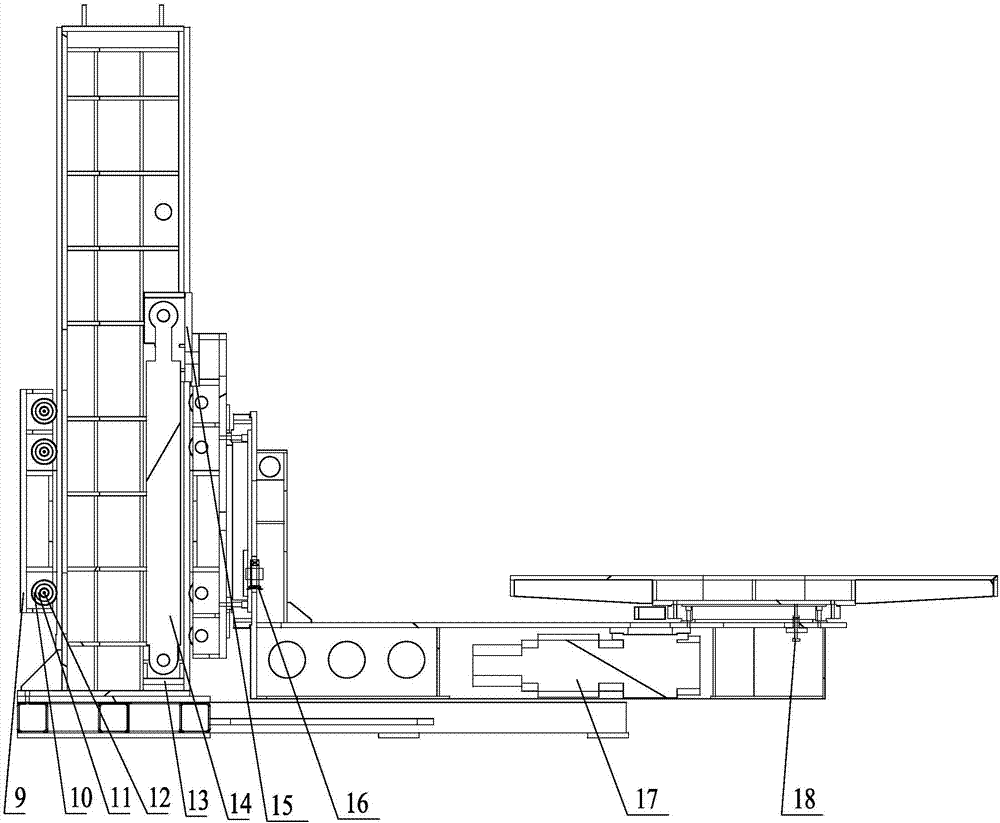

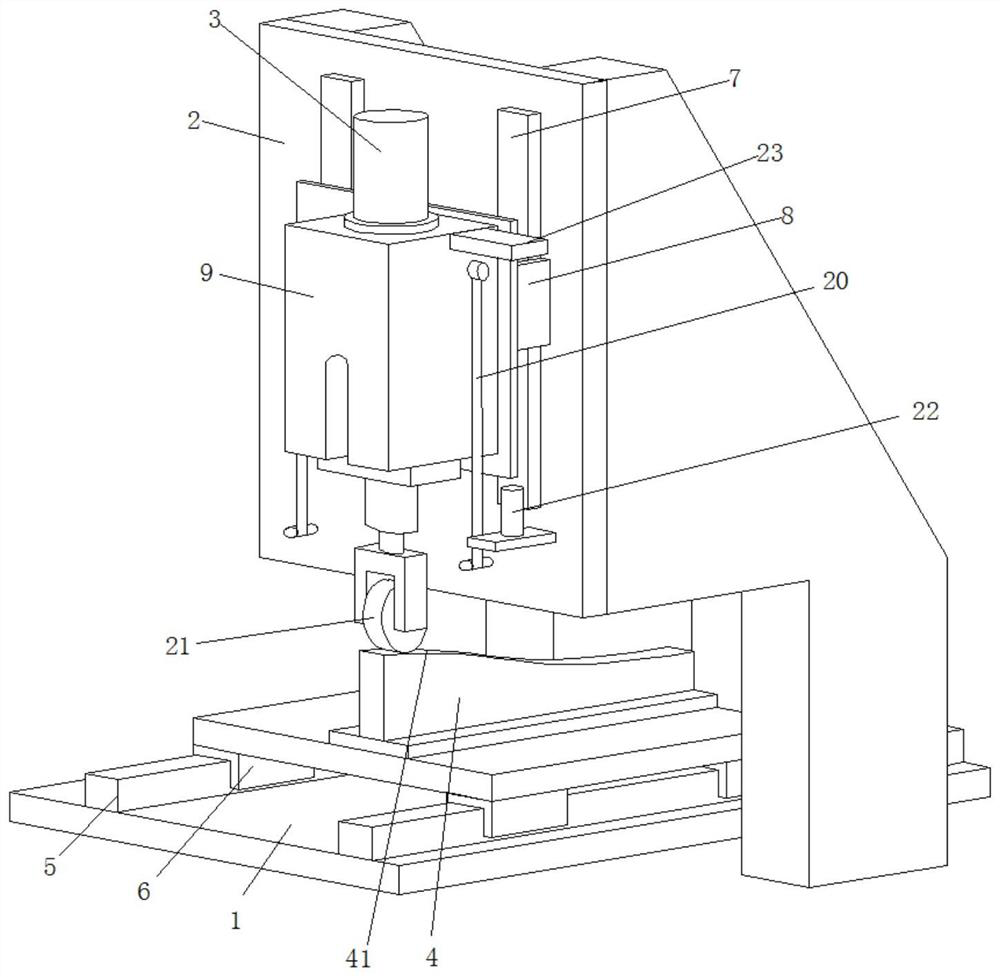

Heavy-load type L-shaped hydraulic lifting welding positioner

InactiveCN107030442AImprove bearing capacityOperator welding safetyWelding/cutting auxillary devicesAuxillary welding devicesHeavy loadIndustrial engineering

The invention belongs to the technical field of welding equipment, and relates to a heavy-load type L-shaped hydraulic lifting welding positioner. The welding positioner comprises a base, wherein box-type stand columns are fixed on the base, a frame-type lifting body is arranged on the surface of the box-type stand columns in a sliding mode, a heavy-load oil cylinder is installed on the bottom plate of the box-type stand columns, a piston rod end of the heavy-load oil cylinder is connected with the frame-type lifting body through an oil cylinder jacking fixing base, a turnover mechanism is arranged on the surface of the frame-type lifting body, a heavy-load cross arm is installed on the turnover mechanism, and the outer end of the heavy-load cross arm is provided with a slewing mechanism for slewing a workpiece. According to the positioner, the equipment is safer and more reliable, and the operation by workers is very convenient and simple.

Owner:无锡市南方电器制造有限公司

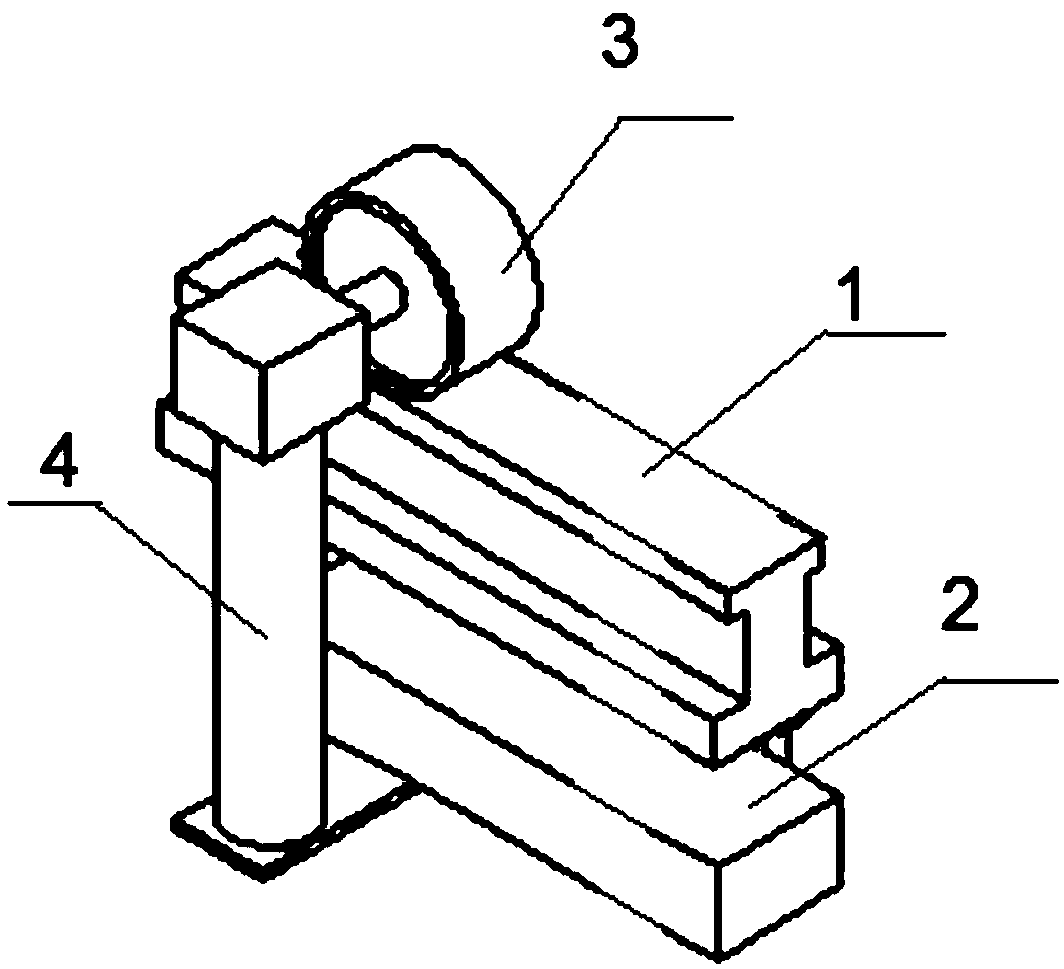

Height adjustment device for shield tunneling machine departure and reception

InactiveCN107130970AEasily adjust height from the groundSolve head sinkingTunnelsEngineeringShield tunneling

The invention provides a height adjustment device for shield tunneling machine departure and reception. The height adjustment device comprises a base, a jack and a wedge-shaped slide block, the jack and the wedge-shaped slide block are arranged on the base, the base is provided with a guide rail, and the wedge-shaped slide block can be driven by the jack to move horizontally along the guide rail. According to the height adjustment device for the shield tunneling machine departure and reception, after a shield tunneling machine rectification oil cylinder is locked, by conduct compression and decompression on a hydraulic jack of the adjustment device, the height between a shield tunneling machine and the ground is easily adjusted, the problem of head sinking or tail sinking of the shield tunneling machine departure and reception can be solved, and the height adjustment device is stable and reliable to support, simple in structure, convenient to operate, low in processing cost, and can be repeatedly utilized.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

Secondary ejecting mechanism

Owner:SUZHOU MITAC PRECISION TECH

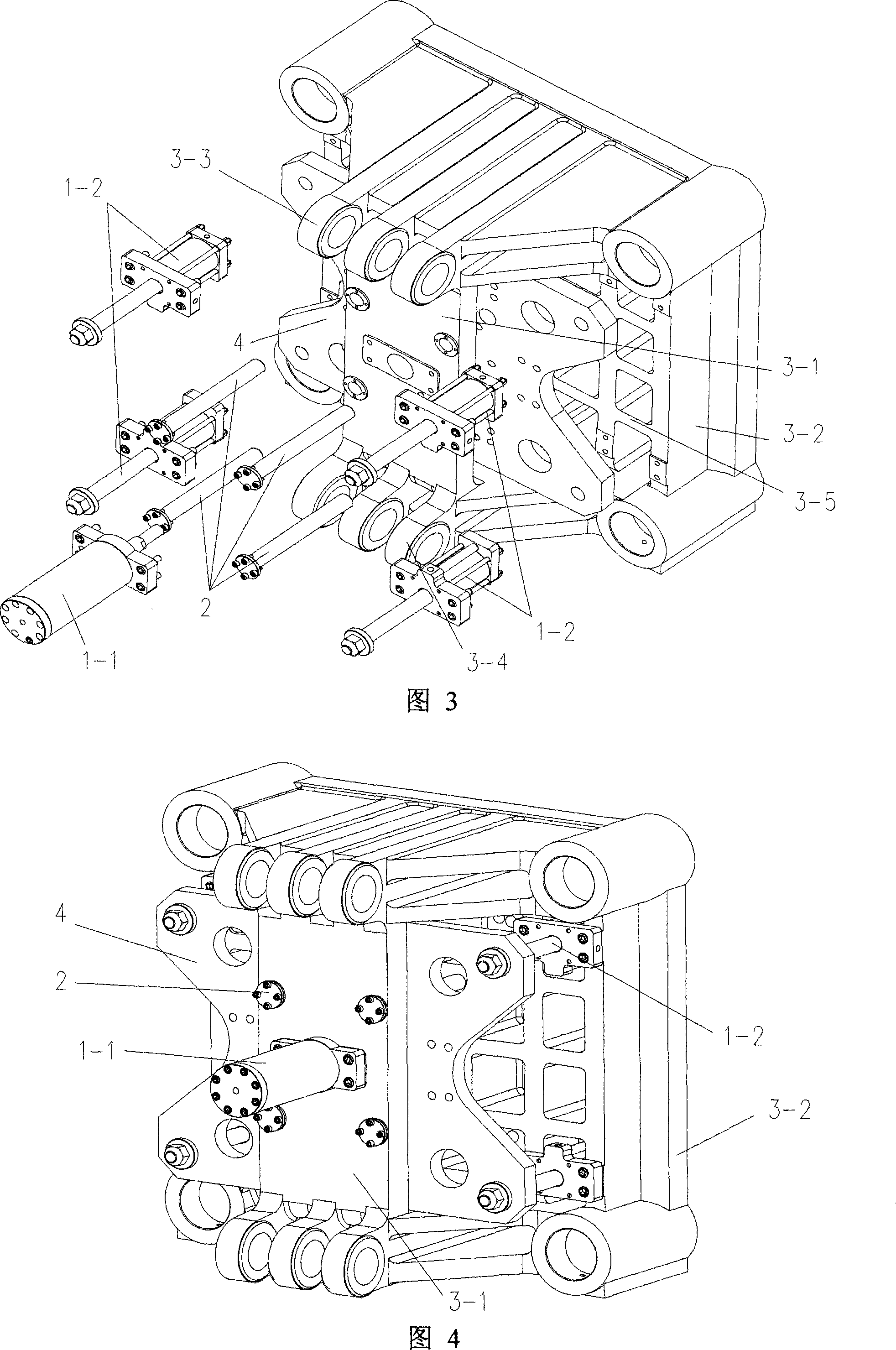

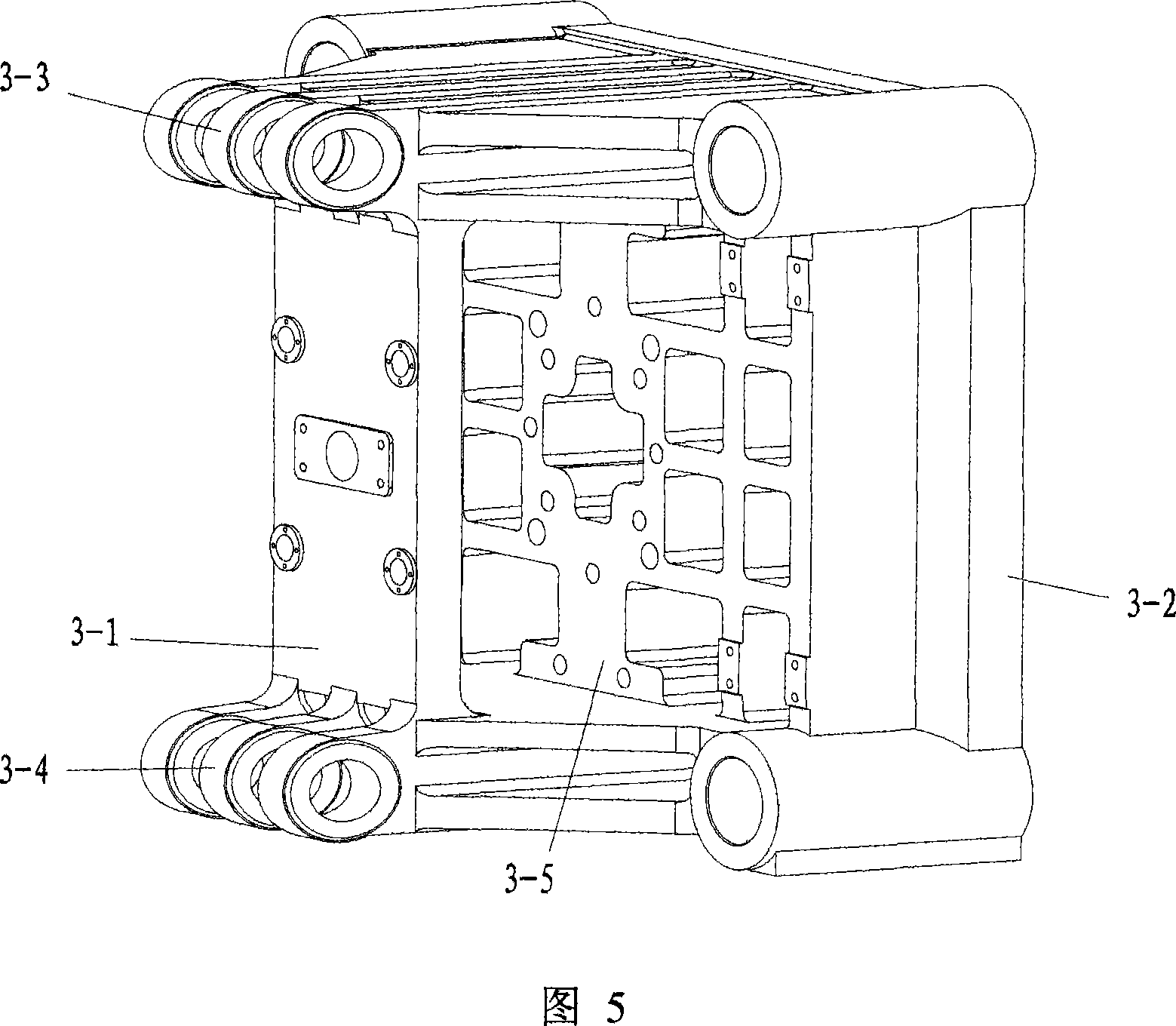

Oblique block elevating mechanism for wafer test

ActiveCN105047575ALarge jacking forceGood jacking stabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDrive motorEngineering

The invention discloses an oblique block elevating mechanism for a wafer test, and aims to solve defects that according to the conventional elevating mechanism for the wafer test, the lifting force is small, the lifting stability is poor, the precision is low, the structure is complex, and the manufacturing cost is high. The oblique block elevating mechanism comprises a base and a supporting plate, a plurality of elevating slide rail seats are fixedly connected on the base, the supporting plate is connected on the elevating slide rail seats in an elevating manner, the base is connected with a supporting seat in a sliding manner, the supporting seat is arranged below the supporting plate, the supporting seat is fixedly connected with a screw rod nut, the base is provided with a driving motor, an output shaft of the driving motor is connected with a screw rod in a transmission manner, the screw rod is connected with the screw rod nut in a cooperation manner, the supporting seat is provided with oblique blocks, the upper end surfaces of the oblique blocks are inclined planes, the supporting plate is provided with rollers, the rollers are abutted against the upper end surfaces of the oblique blocks, a grating scale used for displacement measurement of the supporting plate is arranged between the supporting plate and the base, the driving motor is electrically connected with an encoder, and the grating scale is electrically connected with the encoder.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

Secondary ejecting mechanism of bumper

The invention provides a secondary ejecting mechanism of a bumper. The secondary ejecting mechanism comprises a lower ejecting plate, a groove, a fixing assembly, a rotary ejecting block and a fulcrum shaft, wherein the lower ejecting block is connected to a moving die of an injection molding machine in a contact way; the groove is formed in the moving die of the injection molding machine; the fixing assembly comprises two fixing blocks which are both fixedly arranged in the groove and are respectively located at two opposite sides of the groove; the rotary ejecting block is located between the two fixing blocks, and two ends of the rotary ejecting block are respectively a stressed end facing to a fixed die of the injection molding machine and a force applying end facing to the lower ejecting plate; and the fulcrum shaft is penetrated in the middle section of the rotary ejecting block, and two ends of the fulcrum shaft are respectively arranged on the two fixing blocks. The secondary ejecting mechanism has the beneficial effect that the secondary ejecting mechanism can be arranged on the injection molding machine and can generate an enough ejecting force to help the bumper demold.

Owner:NINGBO SOUTH MOLD & PLASTIC

Upper jacking system with multi-station jacking function

PendingCN111185566AEnsure stabilityExtended service lifeForging/hammering/pressing machinesHydraulic cylinderStructural engineering

The invention provides an upper jacking system with a multi-station jacking function. The upper jacking system comprises a hydraulic cylinder body mounted in a center hole of a sliding block, an upperoil inflow pipeline, a lower oil inflow pipeline, a piston, a piston rod, a flange plate, a check disc mounted on the flange plate through a flange plate countersunk bolt, a base, check disc countersunk bolts, a guide sleeve mounted in a stepped hole in the center of the base, a concave guide column located in the guide sleeve, matched with the guide sleeve and mounted at the end of the piston rod through horizontally-arranged connecting pins, a jacking bottom disc mounted on the end face of the tail end of the concave guide column through jacking bottom disc countersunk bolts and multiple jacking rods mounted on the jacking bottom disc through threaded connection. The upper jacking system is large in jacking force, rapid in action response, high in production efficiency, simple in transmission chain, high in jacking precision, flexible in operation, suitable for automatic production, high in production efficiency, long in service life, high in anti-unbalance-loading capacity and suitable for multi-station forging occasions, and can be widely used for a screw press and especially applied to a large screw press.

Owner:青岛宏达锻压机械有限公司

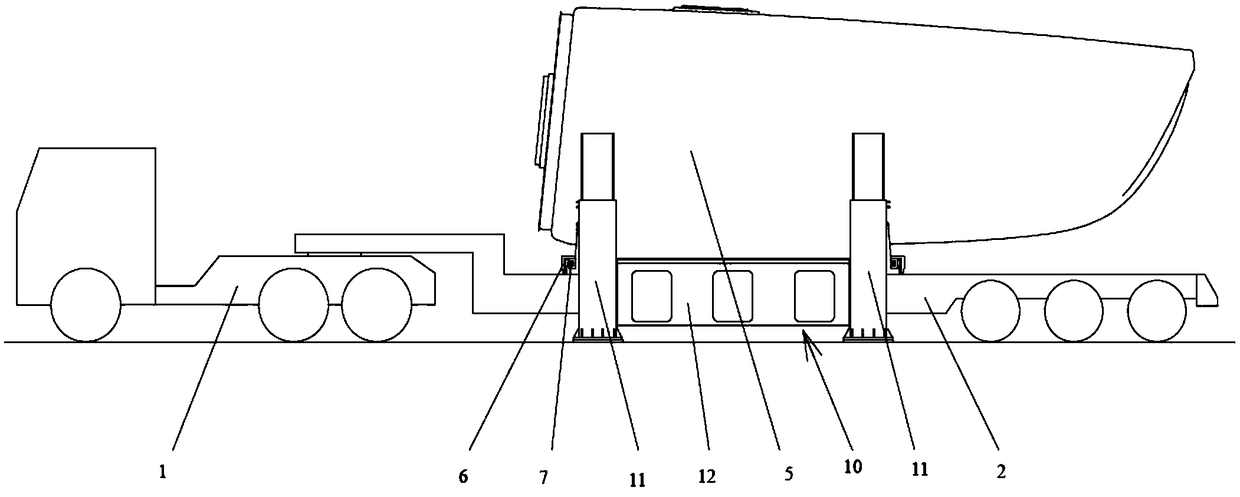

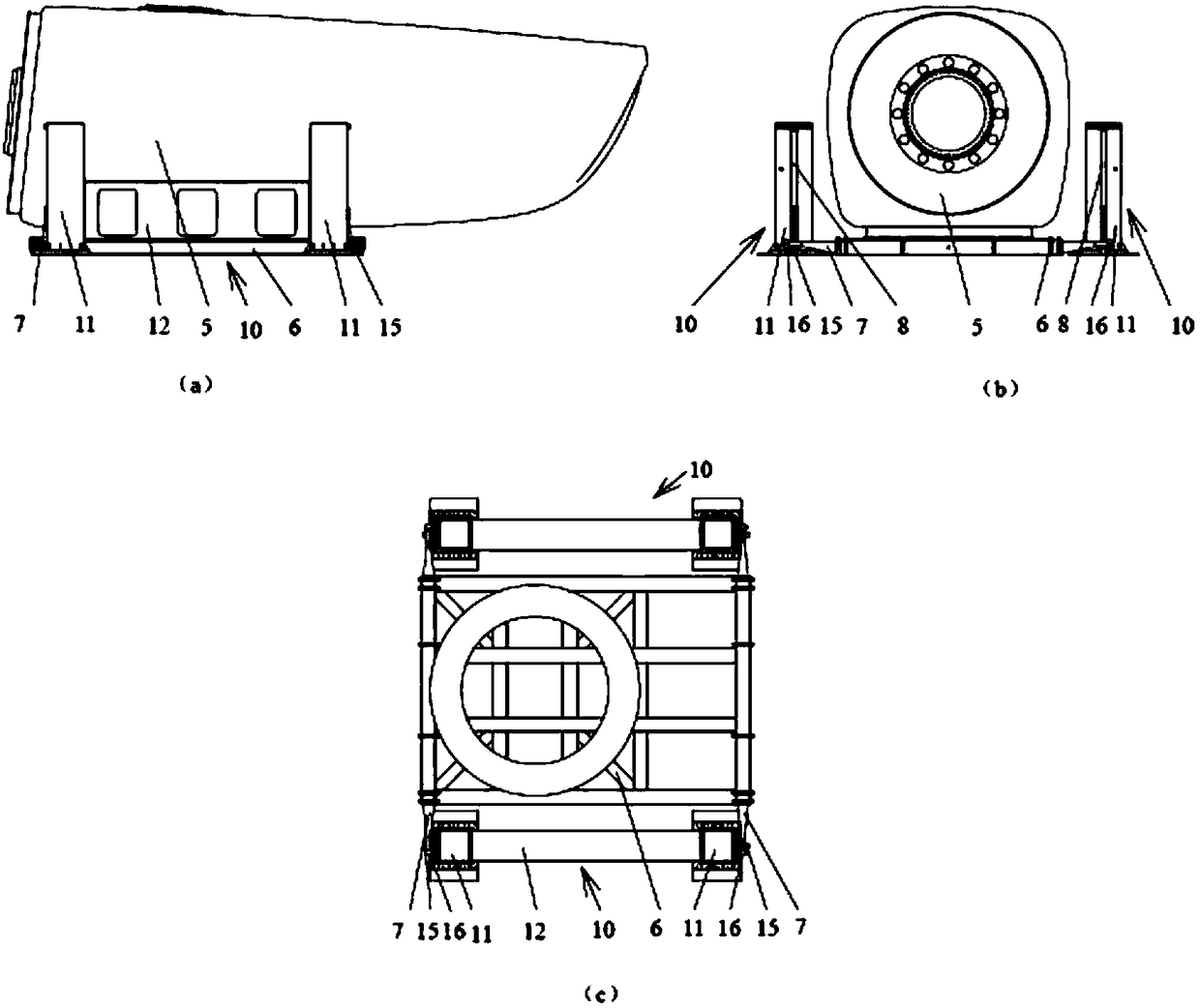

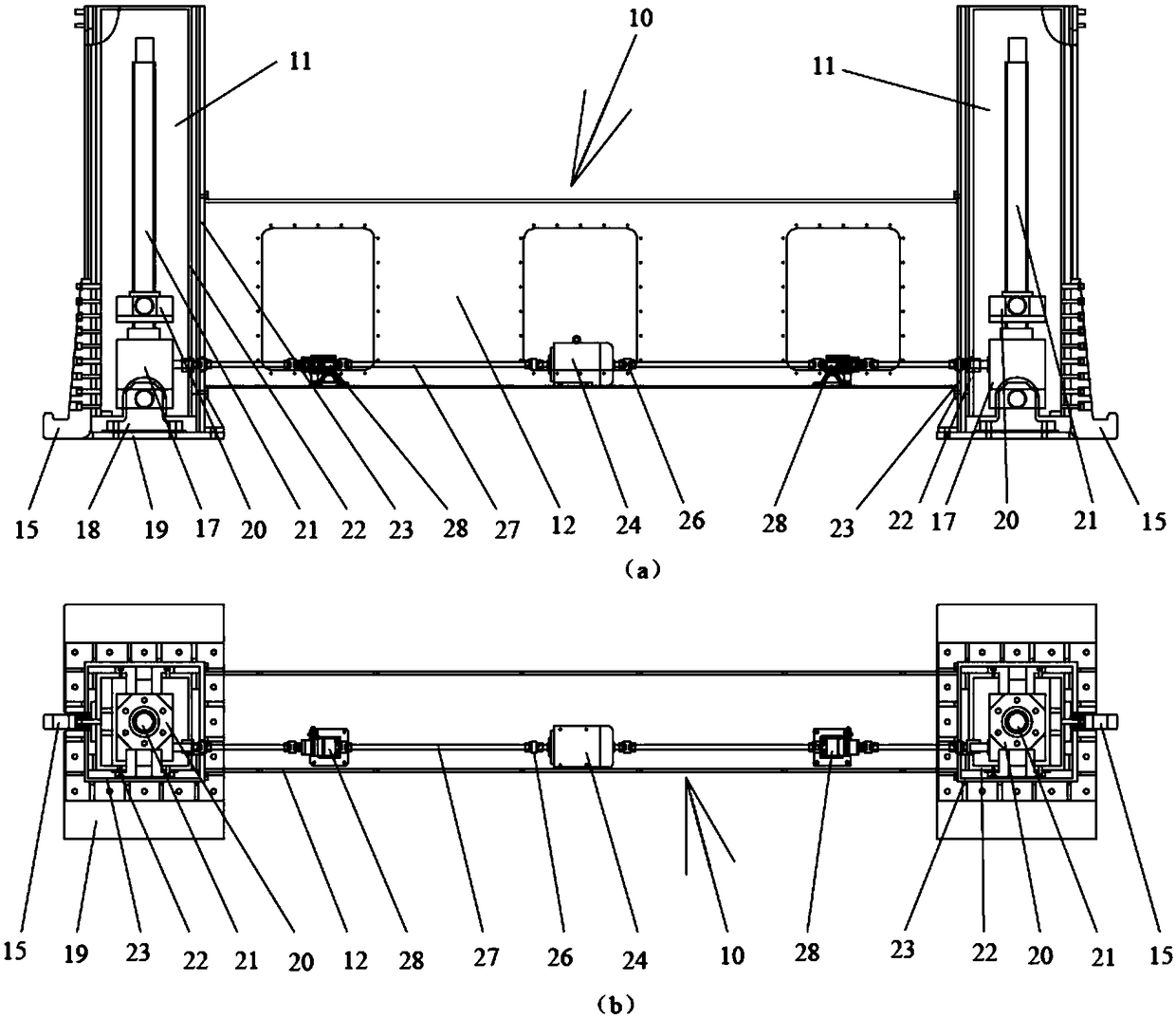

Cabin self-unloading apparatus

ActiveCN108975211AWith self-locking functionBig jacking forceSafety devices for lifting equipmentsLifting framesElectromagnetic clutchCoupling

The invention relates to a cabin self-unloading apparatus. A jacking device is composed of two jacking units, a connection beam that helps adapt the two jacking units, a driving motor, a toothed electromagnetic clutch, a connection shaft and a coupling. Each jacking unit is composed of an outer sleeve, an inner sleeve, a screw lift, a lift support and a base; the screw lift, within the inner sleeve, is hinged to the base via the lift support; a screw nut screwed to a spiral screw of the screw lift is hinged to the inner sleeve; a jacking arm is fixed to the lower end of one side of the inner sleeve; a hook portion arranged at the lowermost end of the jacking arm is extended out of the outer sleeve from an opening of the outer sleeve, and a slide rail and a slider are arranged between the inner sleeve and the outer sleeve. Two longitudinal ends of the connection beam are connected with the outer sleeves of the two jacking units; the openings of the outer sleeves face the longitudinal outer side of the jacking device; the driving motor is disposed in the connection beam; output shafts at the two ends of the driving motor are connected with input shaft on the two sides of the screw lift via the couplings, connection shafts and the toothed electromagnetic clutch.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

Battery jacking assembly and battery steel shell notch forming mechanism

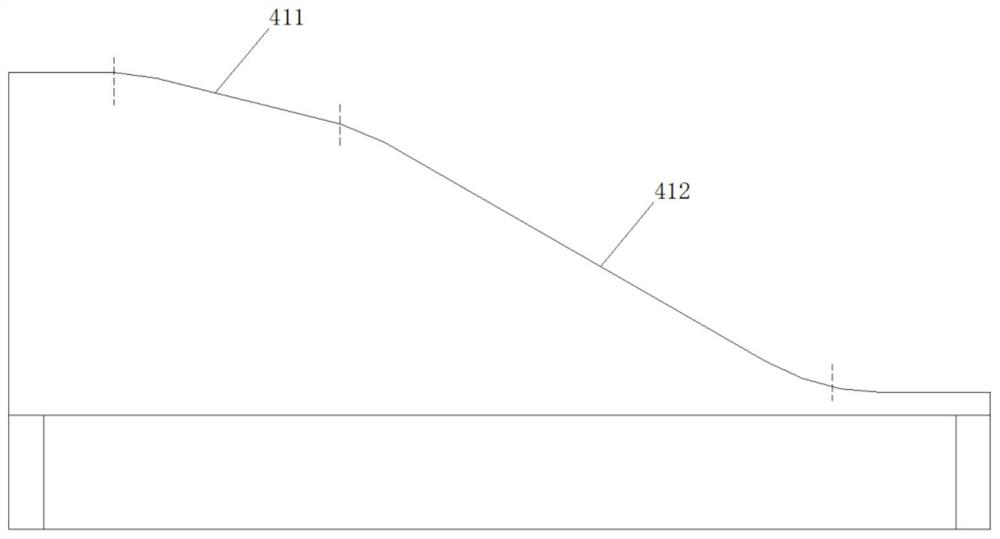

PendingCN112692132AHigh precisionReduce mistakesMetal-working feeding devicesSmall-sized cells cases/jacketsStructural engineeringMechanical engineering

The invention discloses a battery jacking assembly. The battery jacking assembly comprises a bottom plate, a bottom support assembly and a guide block, wherein the bottom plate comprises a bottom plate body and a side plate arranged in the jacking direction of a battery; the bottom support assembly is used for bearing the battery and is arranged on the side plate in a sliding mode, and the sliding direction is the jacking direction; the guide block is arranged on the bottom plate in a sliding mode, and the side face, opposite to the bottom support assembly, of the guide block is used for supporting the bottom support assembly; and the side face, opposite to the bottom support assembly, of the guide block is a curved surface, so that the distance between the end face, used for supporting the battery, of the bottom support assembly and the bottom plate is variable. The guide block with the curved surface is adopted, power of a driving part is converted in two directions through the guide block, the precision can be effectively improved, and the jacking force can be effectively increased.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Multi-ejection type injection molding mold ejection mechanism with main oil cylinder and auxiliary oil cylinder

The invention discloses a multi-ejection type injection molding mold ejection mechanism with a main oil cylinder and an auxiliary oil cylinder. A plurality of ejection rods are uniformly arranged between a movable mold plate and an ejection plate. The multi-ejection type injection molding mold ejection mechanism further comprises the ejection oil cylinders connected with the ejection plate. The ejection oil cylinders comprise the auxiliary ejection oil cylinder and the main ejection oil cylinder. An auxiliary ejection piston rod of the auxiliary ejection oil cylinder is a barrel type piston rod. The inner diameter of the auxiliary ejection piston rod is larger than the diameter of a main ejection piston rod of the main ejection oil cylinder. The auxiliary ejection piston rod and the main ejection piston rod are coaxial. Besides, the main ejection piston rod is arranged in the auxiliary ejection piston rod. The length of the main ejection piston rod is larger than that of the auxiliary ejection piston rod. According to the multi-ejection type injection molding mold ejection mechanism with the main oil cylinder and the auxiliary oil cylinder, the main ejection piston rod is arranged in the auxiliary ejection piston rod, so that a product in a mold is rapidly ejected by means of intermittent movement of the auxiliary ejection piston rod and the main ejection piston rod, and the ejection force is large and is applied uniformly.

Owner:广州一道注塑机械股份有限公司

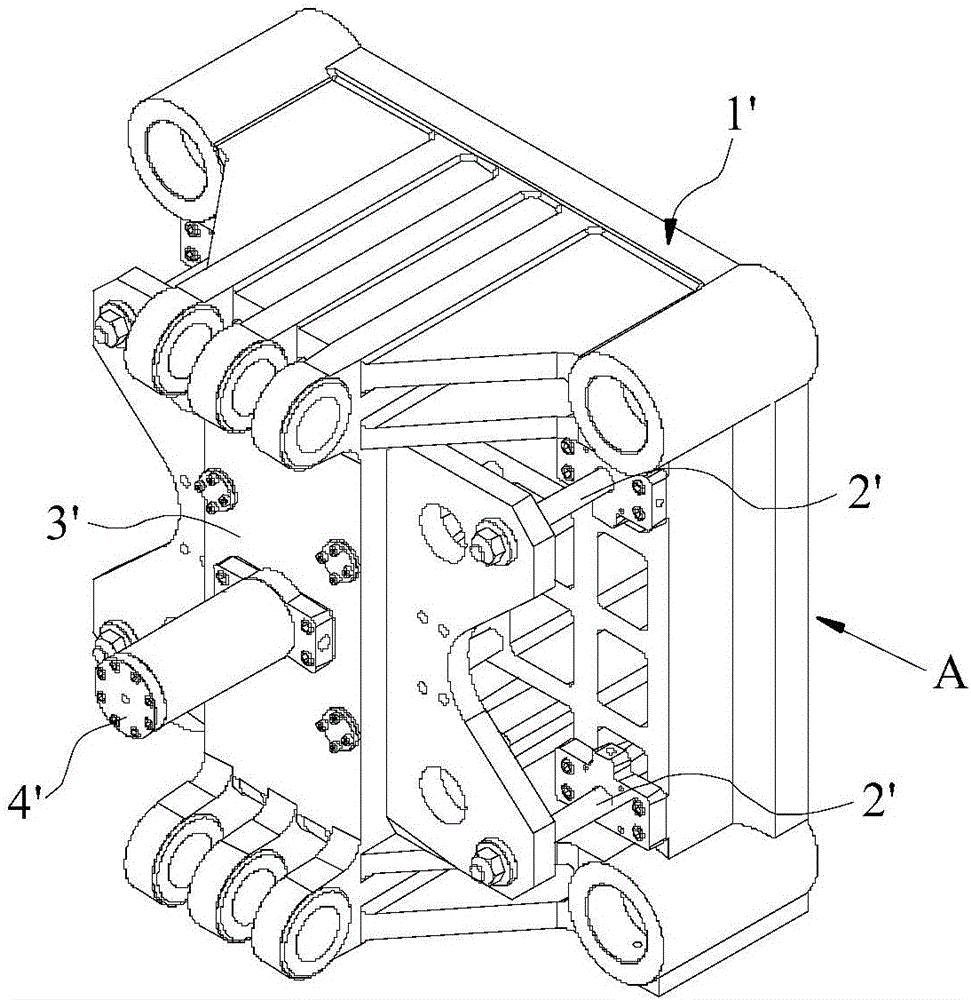

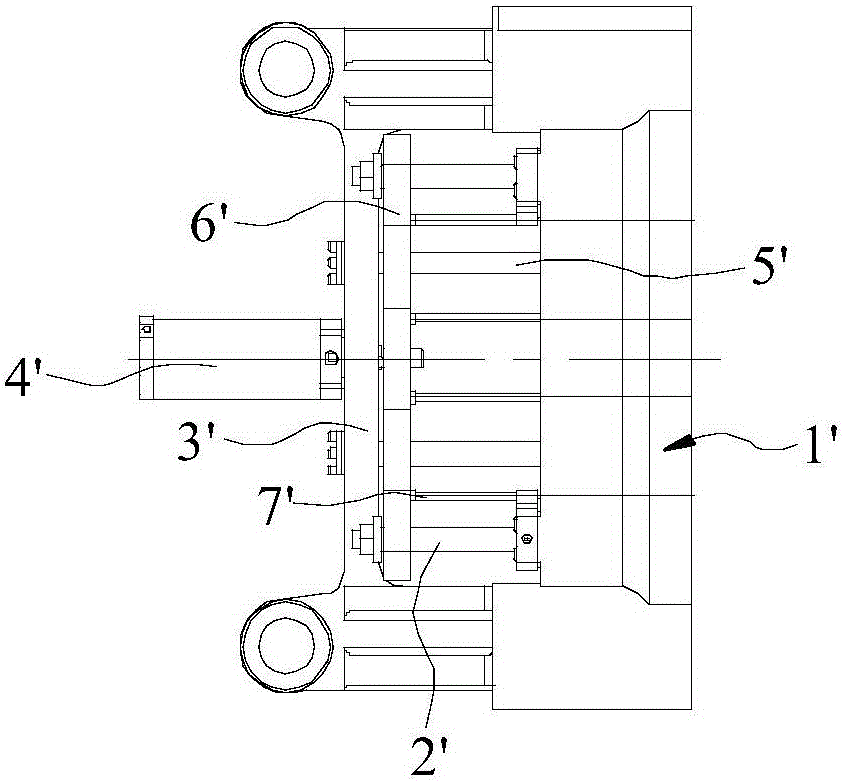

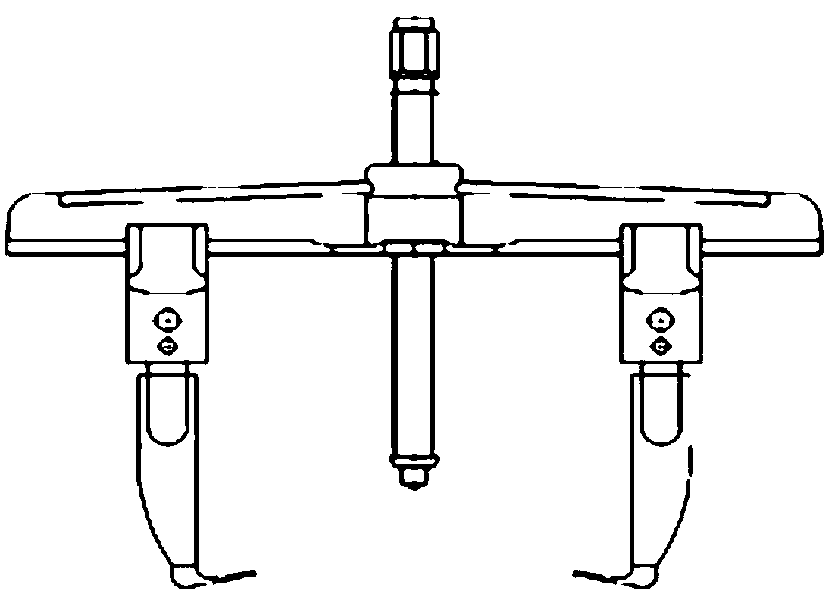

Lifting device of track crane and method for replacing traveling wheel of track crane

PendingCN108726418AReliable clampingBig jacking forceLifting devicesLoad-engaging elementsMechanical engineering

The invention discloses a lifting device of a track crane and a method for replacing a traveling wheel of the track crane, and belongs to the field of hoisting. The lifting device comprises a bearingbody, a clamping assembly movably connected to the lower portion of the bearing body and a power assembly vertically connected with the bearing body; the clamping assembly at least comprises a first clamping arm and a second clamping arm which are arranged in pairs and are adjustable in distance; the bearing body comprises a first sliding track and a second sliding track which are arranged at thetwo sides of the bearing body and matched with the first clamping arm or the second clamping arm, the second sliding track is located at one side of a side beam, and the length of the first sliding track is larger than that of the second sliding track; the power assembly comprises a transmission piece perpendicular to the bearing body and a booster fixedly arranged at one end of the transmission piece; when the track crane is lifted, the booster abuts against a guide track to lift the track crane to be separated from the guide track. According to the lifting device, through the arrangement ofthe asymmetric sliding tracks at the two sides, the total weight can be controlled while the balance is ensured, it is ensured that one person can take, install, use and disassemble the lifting device.

Owner:FAW VOLKSWAGEN AUTOMOTIVE CO LTD

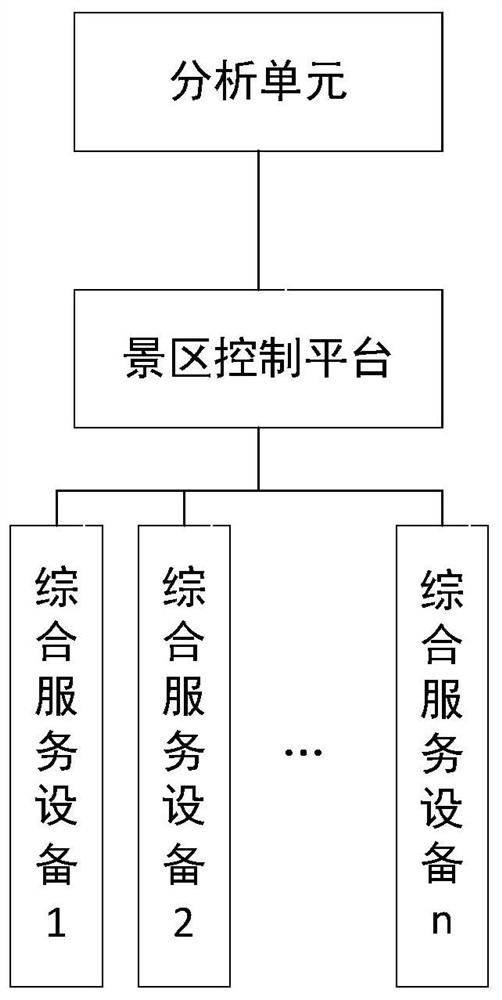

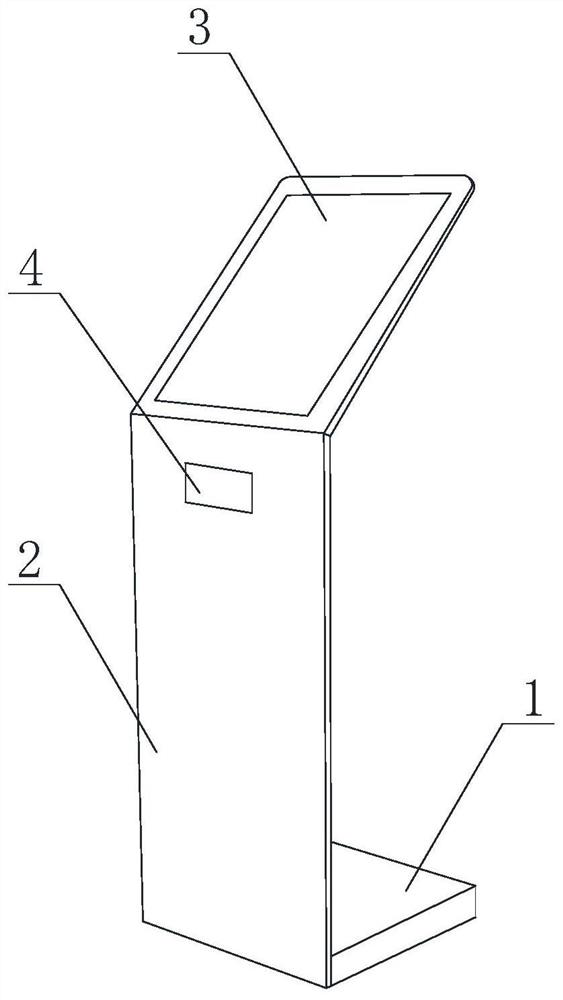

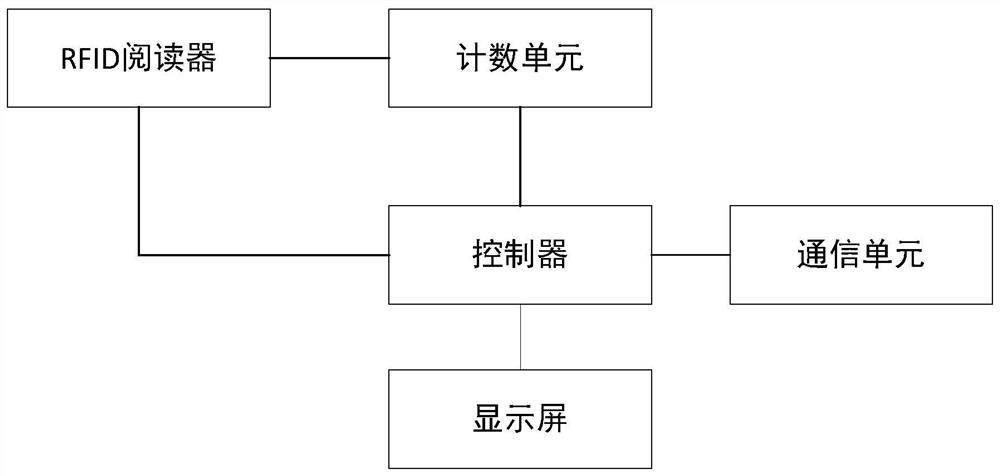

Explanation recommendation system and method based on scenic spot recognition

PendingCN112071243AEasy to manageImprove experienceAdvertisingShort range communication serviceData informationEngineering

The invention relates to an explanation recommendation system and method based on scenic spot identification. The method comprises the following steps: after comprehensive service equipment of each scenic spot in a scenic area reads an electronic tag of a tourist terminal through an RFID reader, the comprehensive service equipment transmits tourist data information and time information contained in the electronic tag, the tag reading frequency information and position information to a scenic area control platform; the scenic area control platform sends the information to an analysis unit, andthe analysis unit classifies, stores and counts the information and grades the scenic spots according to statistical results of various data; and the number of service devices in the scenic spots is adjusted according to the scenic spot grading result. According to the system and the method, big data statistics of the scenic area control platform is facilitated, objective data reference is provided for comprehensively regulating and controlling the position and the number of comprehensive service equipment in each scenic spot by taking tourists as guidance in the scenic area, scenic area management is enhanced, resource waste caused by careless management is reduced, and the tourist experience is improved.

Owner:成都网传文化传播有限公司

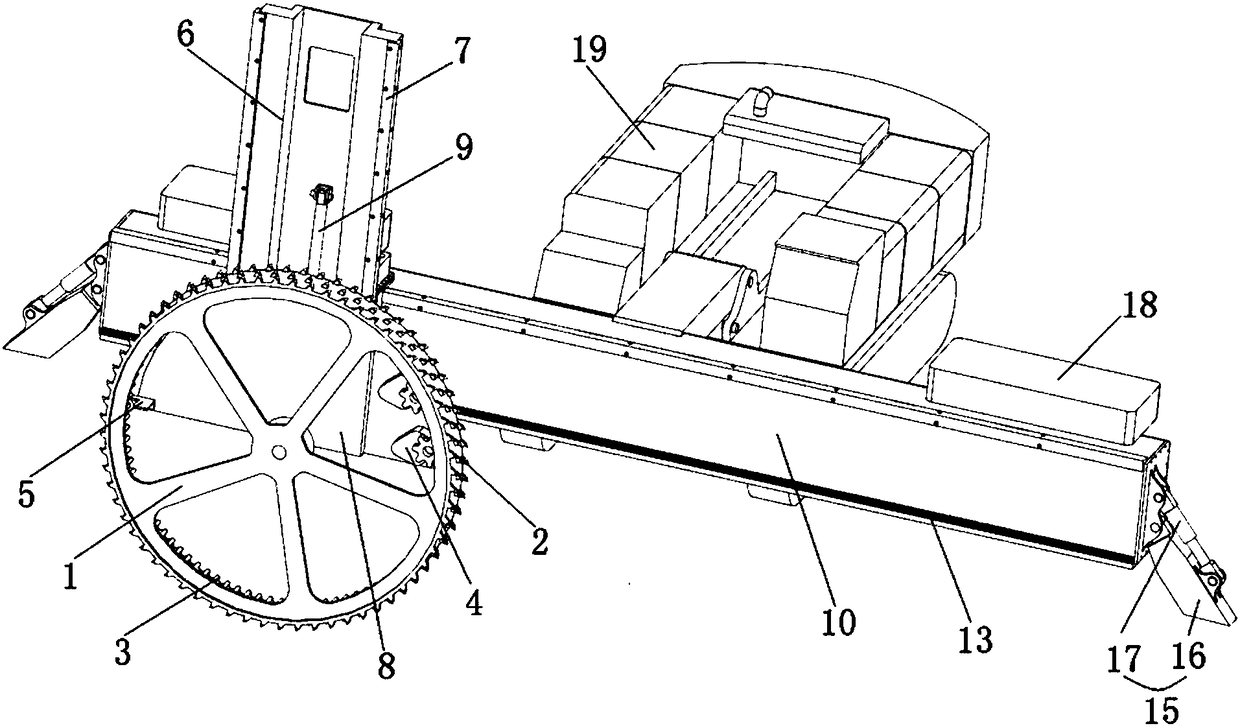

Ditching device and rock stratum mining method using ditching device

PendingCN108071393AEnsure cutting efficiencyStable structureDriving meansCutting machinesTerrainEngineering

The invention discloses a ditching device. The ditching device is characterized by comprising a ditching and cutting mechanism, a digging mechanism and a horizontal movement mechanism, the digging mechanism drives the ditching and cutting mechanism to move up and down, and the horizontal movement mechanism drives the ditching and cutting mechanism to move along a main cross beam. The ditching andcutting mechanism is composed of a cutting frame, a cutting drive mechanism and cutting convex teeth, the cutting frame rotates around a shaft, the cutting drive mechanism drives the cutting frame torotate, and the cutting convex teeth are arranged on the cutting frame and rotate along with the cutting frame. According to the ditching device, the cutting convex teeth rotating along with the cutting frame are used for cutting and ditching, when the cutting frame rotates, low rotation speed and large torque can be achieved, the cutting frame can provide stable and enough pushing force for the cutting convex teeth, and the cutting convex teeth thus can effectively cut hard rock. The cutting force is effectively improved, the ditching efficiency is guaranteed, the device is suitable for all kinds of complicated terrains, the ditching equipment is adopted for rock stratum mining, high-efficiency mining is achieved, and the operation cost is low.

Owner:四川猎石者龙宇科技有限公司

Novel fixed mold ejecting mechanism

The invention discloses a novel fixed mold ejecting mechanism. The novel fixed mold ejecting mechanism comprises a mold sleeve plate and an ejecting mechanism body, wherein a fixed mold core is inlaidin one end face of the mold sleeve plate, and an accommodating cavity which is concave towards the interior of the mold sleeve plate is formed in the other end face of the mold sleeve plate; the ejecting mechanism body comprises a jacking driver and an ejecting assembly driven by the jacking driver; and the jacking driver is arranged in the accommodating cavity, and the ejecting assembly sequentially penetrates through the fixed mold sleeve plate and the fixed mold core from the accommodating cavity to reach the interior of a forming cavity of the fixed mold core. According to the novel fixedmold ejecting mechanism, the jacking driver is adopted, so that the ejecting force is large enough when the thickness of a fixed mold is small; and assembly is convenient, and incorrect assembly is unlikely to occur.

Owner:SUZHOU GUANGXING MOLD

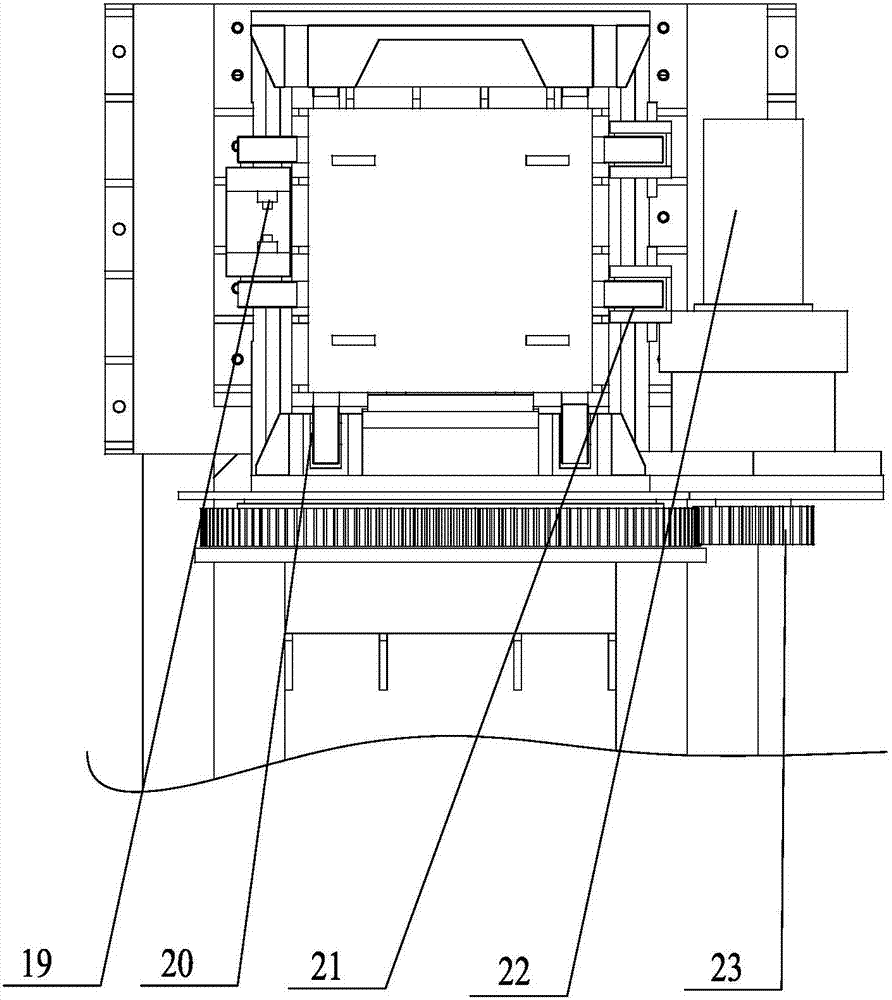

Drawing ejector rod mis-assembling detection system and automatic die changing method for punching line

InactiveCN112044981AEasy to detect wrong installationReduce die change timeShaping safety devicesMetal working apparatusPunchingEngineering

The invention relates to a drawing ejector rod mis-assembling detection system and an automatic die changing method for a punching line. The drawing ejector rod mis-assembling detection system comprises a supporting plate, a driving device, a sensor and a control device, and the supporting plate is used for bearing a drawing ejector rod; the driving device is connected with the supporting plate and is used for driving the supporting plate to vertically eject the ejector rod; the sensor is connected with the driving device and is used for measuring the jacking force of the driving device; and the control device is connected with the driving device and the sensor, and the control device is used for controlling the driving device to work and judging whether the mis-assembled drawing ejector rod exists or not according to the relation between the jacking force measured by the sensor within the set time and a set threshold value. According to the drawing ejector rod mis-assembling detectionsystem and the automatic die changing method for the punching line, the problems of long whole-line die changing time and low equipment starting rate in related technologies can be solved.

Owner:DONGFENG MOTOR CORP HUBEI

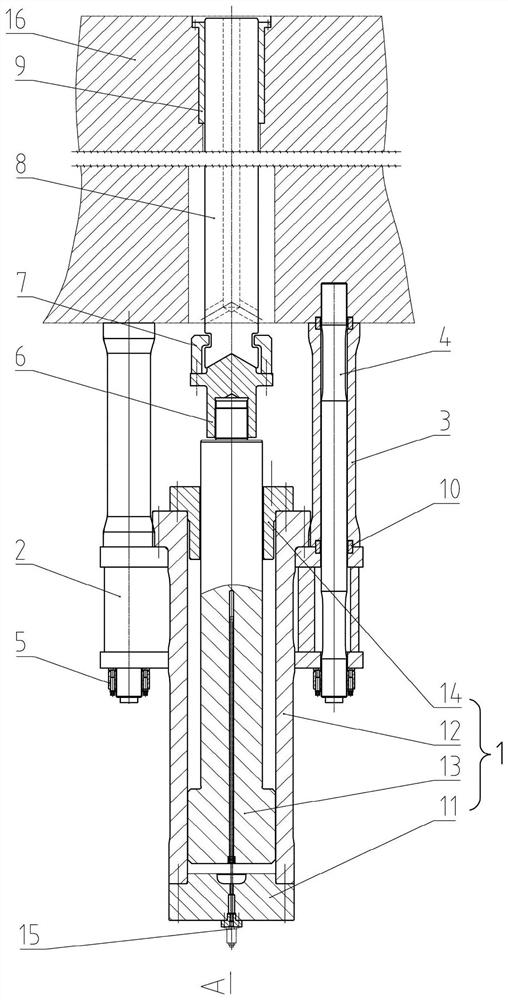

Lower die ejector of forging die

The invention discloses a lower die ejector of a forging die, mainly comprising a central lower die ejector rod 3 and auxiliary lower die ejector rods 4, wherein the central lower die ejector rod 3 is connected with each auxiliary lower die ejector rod 4 by an ejector rod upper plate 9, an ejector rod lower plate 8, a central clamping plate 7 and an auxiliary clamping plate 6; and the ejector rod upper plate 9 and the ejector lower plate 8 are connected by a bolt 10. In the lower die ejector of a forging die, the ejection force to a forging blank is greatly increased through the addition of the auxiliary ejector rods, thereby smoothly ejecting relatively-large forging blanks out.

Owner:CITIC DICASTAL

A lower ejector device for heavy-duty forging machine

ActiveCN112247061BSports reliableMeet the jacking force requirementsForging/hammering/pressing machinesHydraulic cylinderClassical mechanics

A lower ejector device for a heavy-duty forging machine, including a forging machine base, a hydraulic cylinder, a support mechanism, and an ejector mechanism. The ejector mechanism includes a pressure pad, a hook plate, and an ejector rod. The pressure pad is installed on the piston rod. At the top, the hook-shaped plate is fixed on the pressure pad, the bottom of the ejector rod fits with the top surface of the pressure pad, the ejector rod is placed in the ejection hole on the base of the forging machine, and the displacement sensor is installed at the bottom of the hydraulic cylinder; the supporting mechanism includes The lower ejecting beam, column, pull rod, pre-tightening nut and positioning key, the cylinder body of the hydraulic cylinder is installed on the lower ejecting beam, the positioning key is installed at the upper and lower ports of the column, the upper ends of the four pulling rods are fixed on the base of the forging machine, and the lower ends are After passing through the column and the lower ejection beam, pre-tighten it with the pre-tightening nut, and fix the column between the lower ejection beam and the base of the forging machine. The beneficial effect is that the movement of the ejector rod is stable and reliable, and the ejection force is large; the lower ejection beam can bear greater ejection force. The magnetostrictive linear displacement sensor can ensure the displacement accuracy requirements of the ejector rod.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com