Inclined shaft TBM tunneling system and tunneling method

A technology for inclined wells and propulsion cylinders, which is applied in wellbore lining, shaft equipment, earthwork drilling and production, etc. It can solve the problems of increased length of TBM in inclined wells, achieve the effect of reducing the total length and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

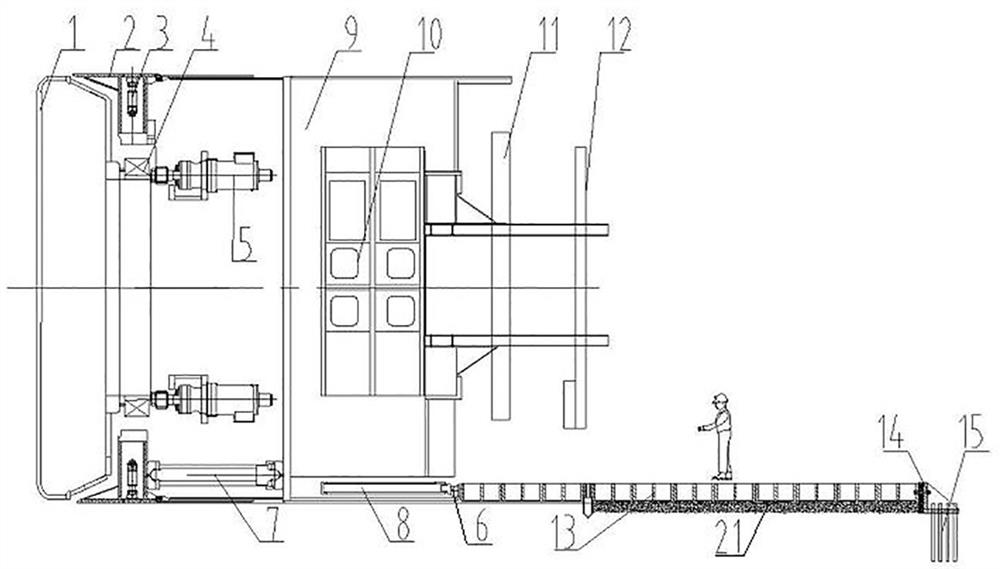

[0059] like figure 1 As shown, the inclined shaft TBM excavation system includes a front shield 2 and a support shield 9, a driving device is provided inside the front shield 2, and a cutterhead 1 is provided at the front end of the front shield 2. The driving device includes a driving motor 5 and a transmission mechanism 4, and the driving device When the motor 5 works, the cutter head 1 is driven to rotate through the transmission mechanism 4, so as to realize the cutting of the soil.

[0060] In this embodiment, the front end of the support shield 9 is inserted into the rear end of the front shield 2, and a propulsion cylinder 7 is provided between the support shield 9 and the front shield 2, so that the front shield 2 moves forward relative to the support shield 9 in the front-rear direction. move. Wherein, one end of the propulsion cylinder 7 is connected to the bottom of the support shield 9, and the other end of the propulsion cylinder 7 is connected to the bottom of t...

Embodiment 2

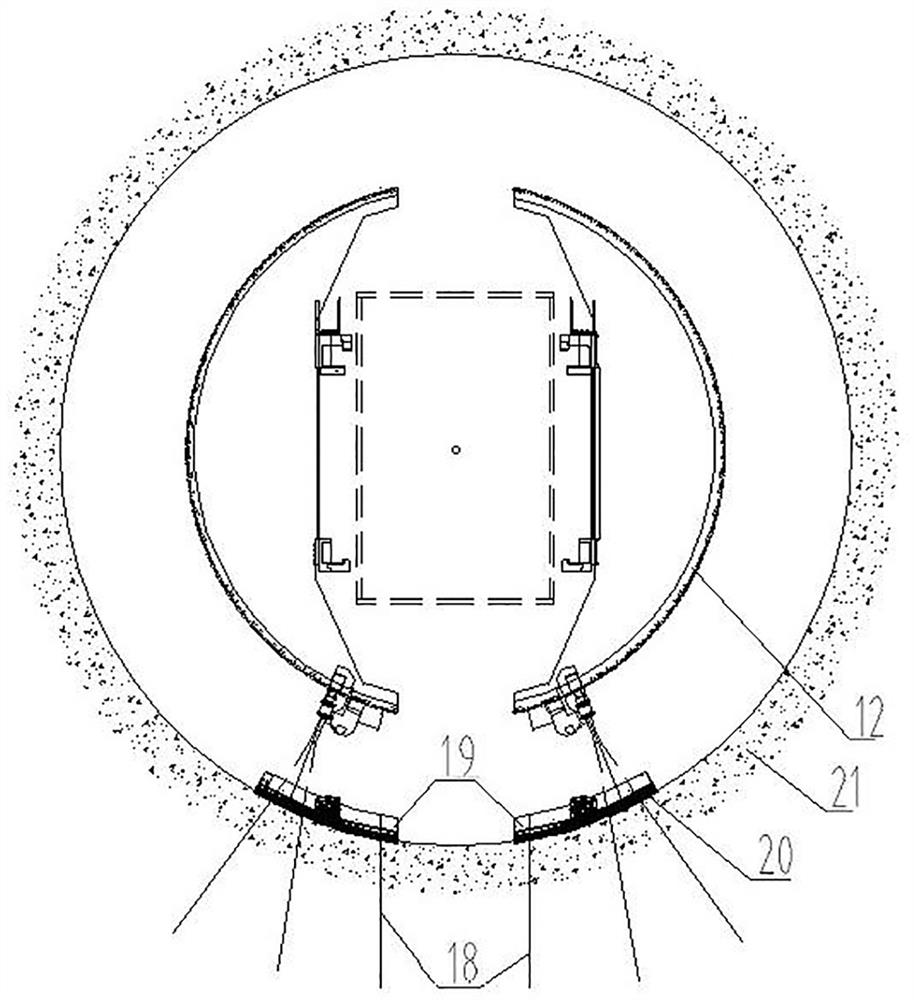

[0082] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, an arch concrete layer 20 is provided between the arch 19 and the arch anchor 18 to improve the stability of the arch. In this embodiment, the arch concrete layer is not provided, and the stability of the arch is improved by increasing the diameter and quantity of the anchor rods of the arch.

Embodiment 3

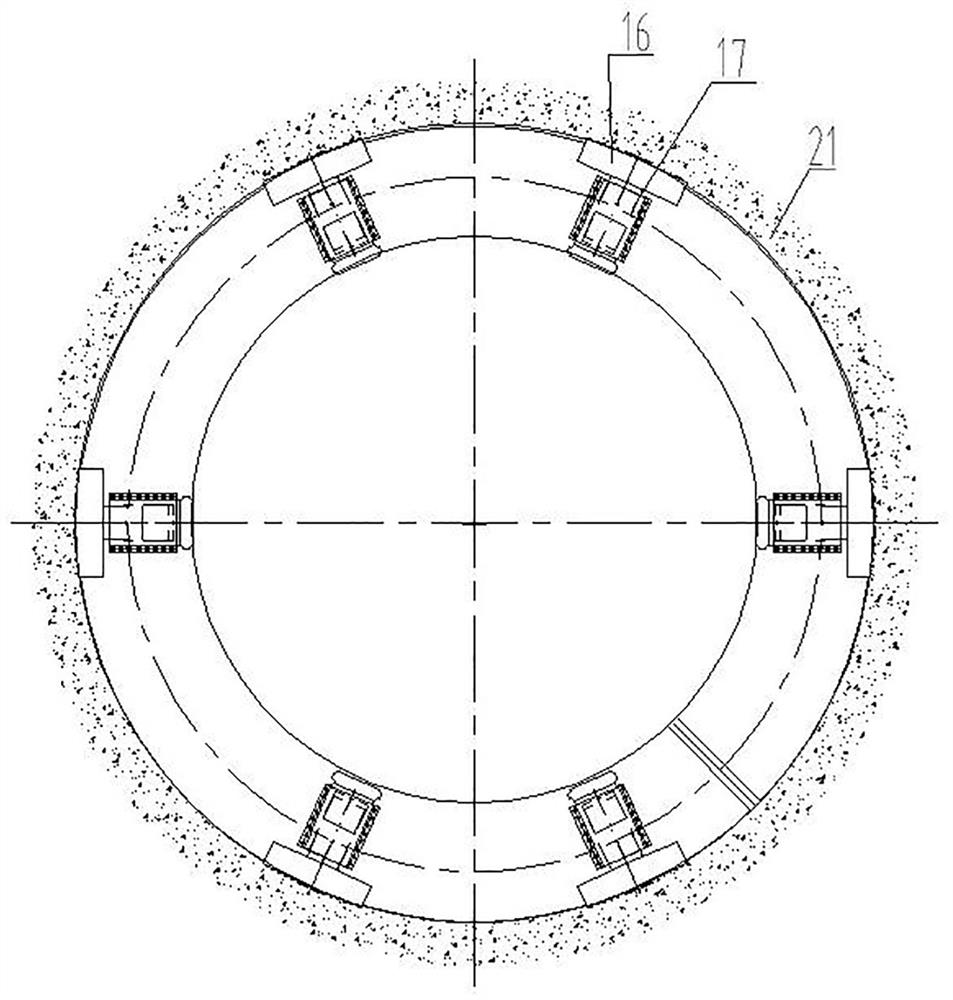

[0084] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the support assembly 13 includes a plurality of arches 19 , and all the arches 19 of the support assembly 13 are arranged in abutment along the front-rear direction. In this embodiment, based on the fact that the support assembly includes a plurality of arches, all the arches of the support assembly are arranged at intervals along the front-rear direction, and the distance between two adjacent arches is equal to one excavation stroke of the inclined shaft TBM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com