Heavy-load type L-shaped hydraulic lifting welding positioner

A welding positioner, hydraulic lifting technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of large lifting force, safe operation and welding personnel, and safe and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

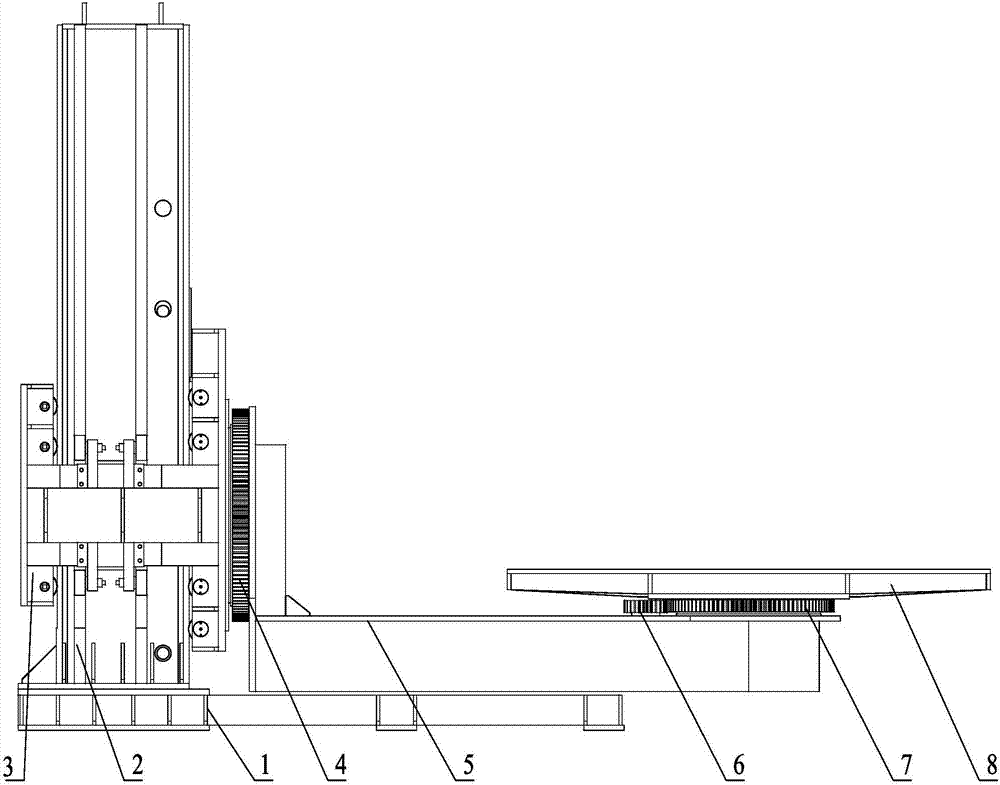

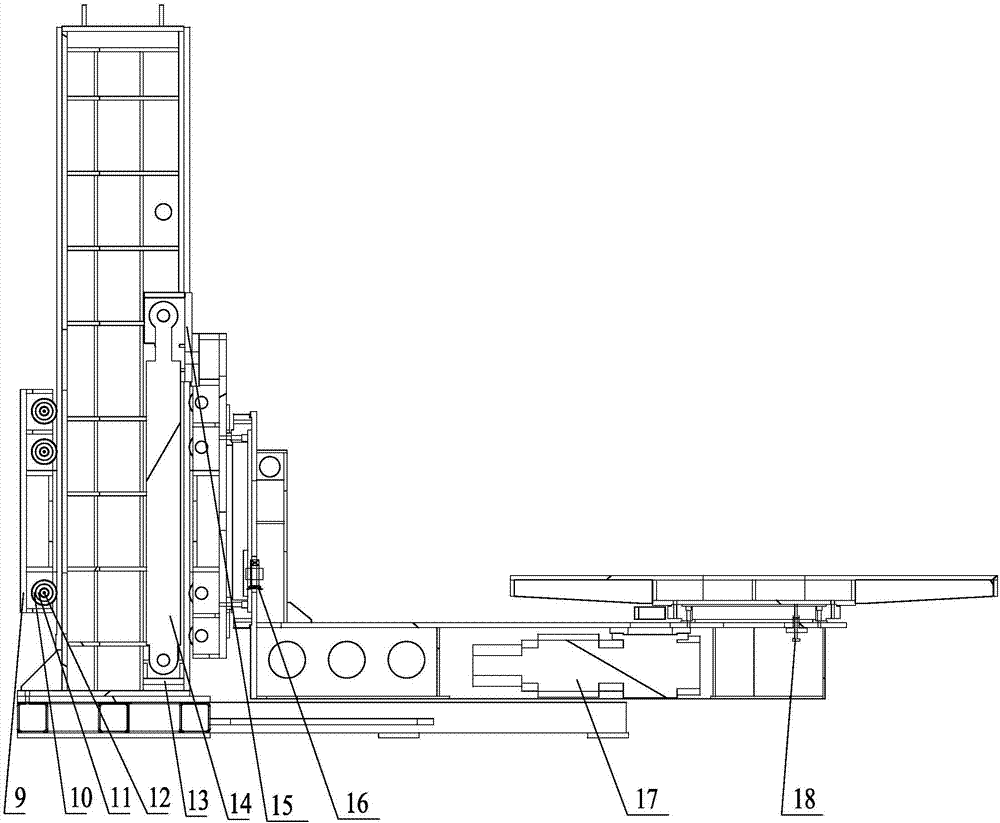

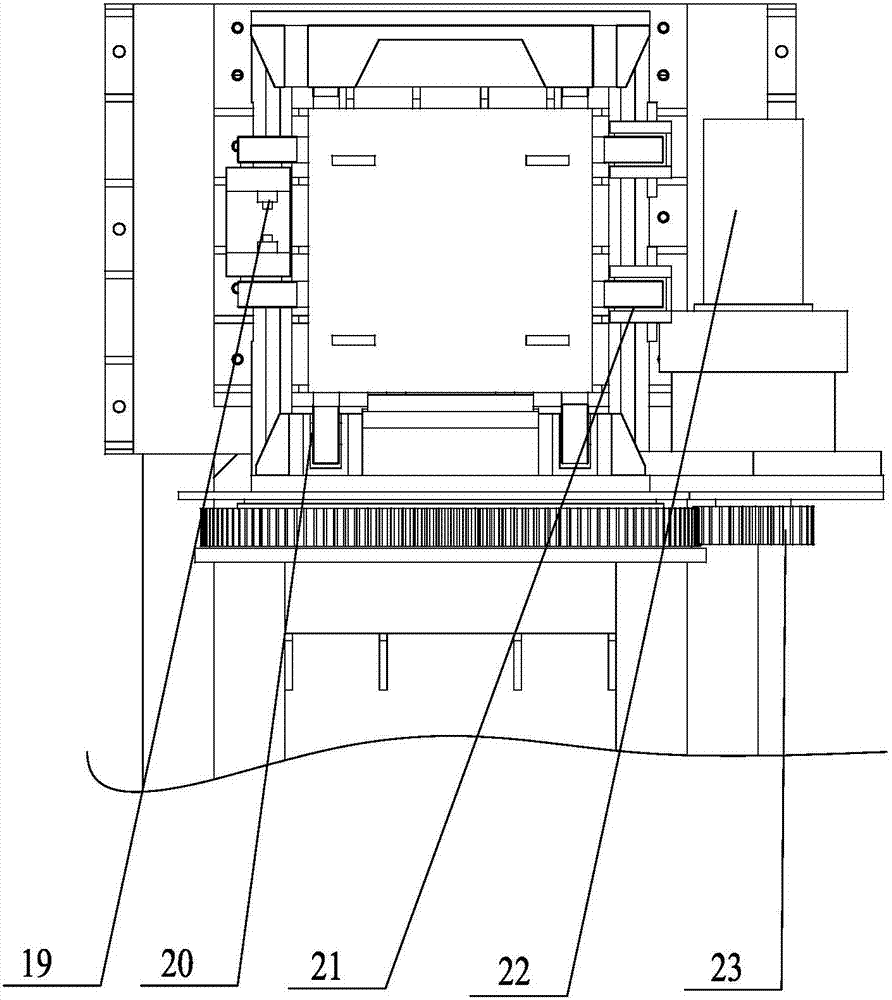

[0017] Figure 1~3 Among them, including base 1, box-type column 2, frame-type lifting body 3, slewing bearing 1 4, heavy-duty cross arm 5, slewing gear 6, slewing bearing 2 7, slewing disc 8, lifting body frame 9, roller 10, inner Bearing 11, eccentric wheel shaft 1 12, oil cylinder installation base 13, heavy-duty oil cylinder 14, oil cylinder jacking fixing seat 15, conductive slip ring 16, rotary brake motor reducer 17, copper rod conductive mechanism 18, eccentric wheel shaft 2 19, front Non-eccentric axle 20, side non-eccentric axle 21, etc.

[0018] Such as Figure 1~3 As shown, the present invention is a heavy-duty L-type hydraulic lifting welding positioner, including a base 1, a box-type column 2 is fixed on the base 1, and a box-type lifting body 3 is installed slidingly on the surface of the box-type column 2. The box-type A h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com