Height adjustment device for shield tunneling machine departure and reception

A technology of height adjustment device and hole entry and exit, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of limited adjustment device structure, damaged shield machine structure, difficult posture adjustment, etc., and achieves simple structure, high thrust The effect of large, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

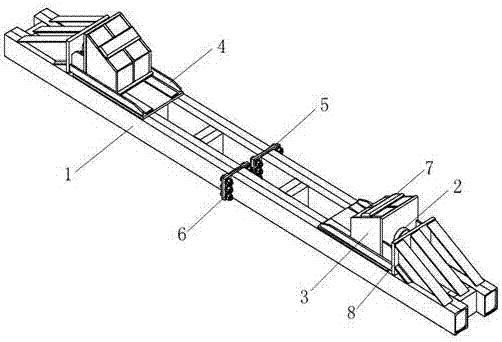

[0021] This embodiment provides a height adjustment device for a shield machine to enter and exit a hole, including a base 1, a pair of jacks 2 and a pair of wedge-shaped sliders 3 arranged on the base 1, the base 1 is provided with guide rails 4, wedge-shaped sliders The block 3 can move horizontally along the guide rail 4 under the push of the jack. Further, the base 1 is in the shape of a strip, the wedge-shaped slider 3 and the jack 2 are arranged at both ends of the strip-shaped base in axisymmetric manner, and the wedge-shaped slider 3 is movably embedded in the guide rail 4, and the The two jacks 2 are respectively located outside the two wedge-shaped sliders.

[0022] The base can be an integral structure or a split structure. If a split structure is adopted, the two bases are connected at the end far away from the jack: the two bases can be connected by bolts. The backing plate 5 is provided with a through hole, and the two backing plates are fastened and connected ...

Embodiment 2

[0025] This embodiment provides a height adjustment device for shield tunneling. The design concept is basically the same as that of Embodiment 1. The difference is that in this embodiment, a limit module 8 is added to the base, and the limit module 8 is fixedly connected to the base 1. Above; the jack 2 is located between the limiting module 8 and the wedge-shaped slider 3, and the wedge-shaped slider 3 is movably embedded on the guide rail 4; the limiting module 8 is fixed on the base 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com