Cabin self-unloading apparatus

A technology of self-unloading device and engine room, which is applied in the direction of hoisting device, lifting equipment safety device, lifting frame, etc. It can solve the problems of unusable, loading and unloading engine room, and immovable devices, etc., and achieves low operating cost, good synchronization, and top big lift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

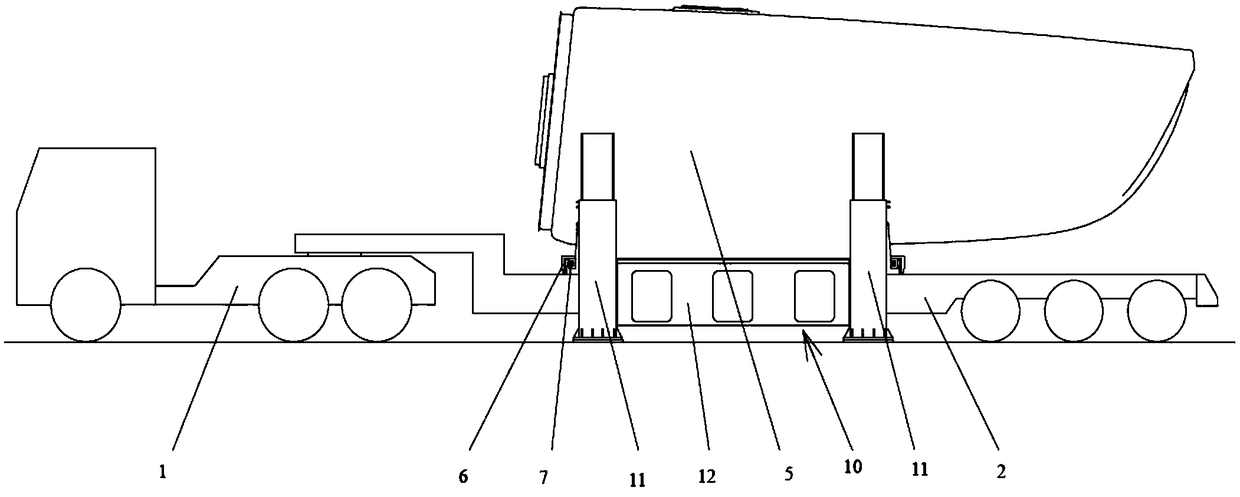

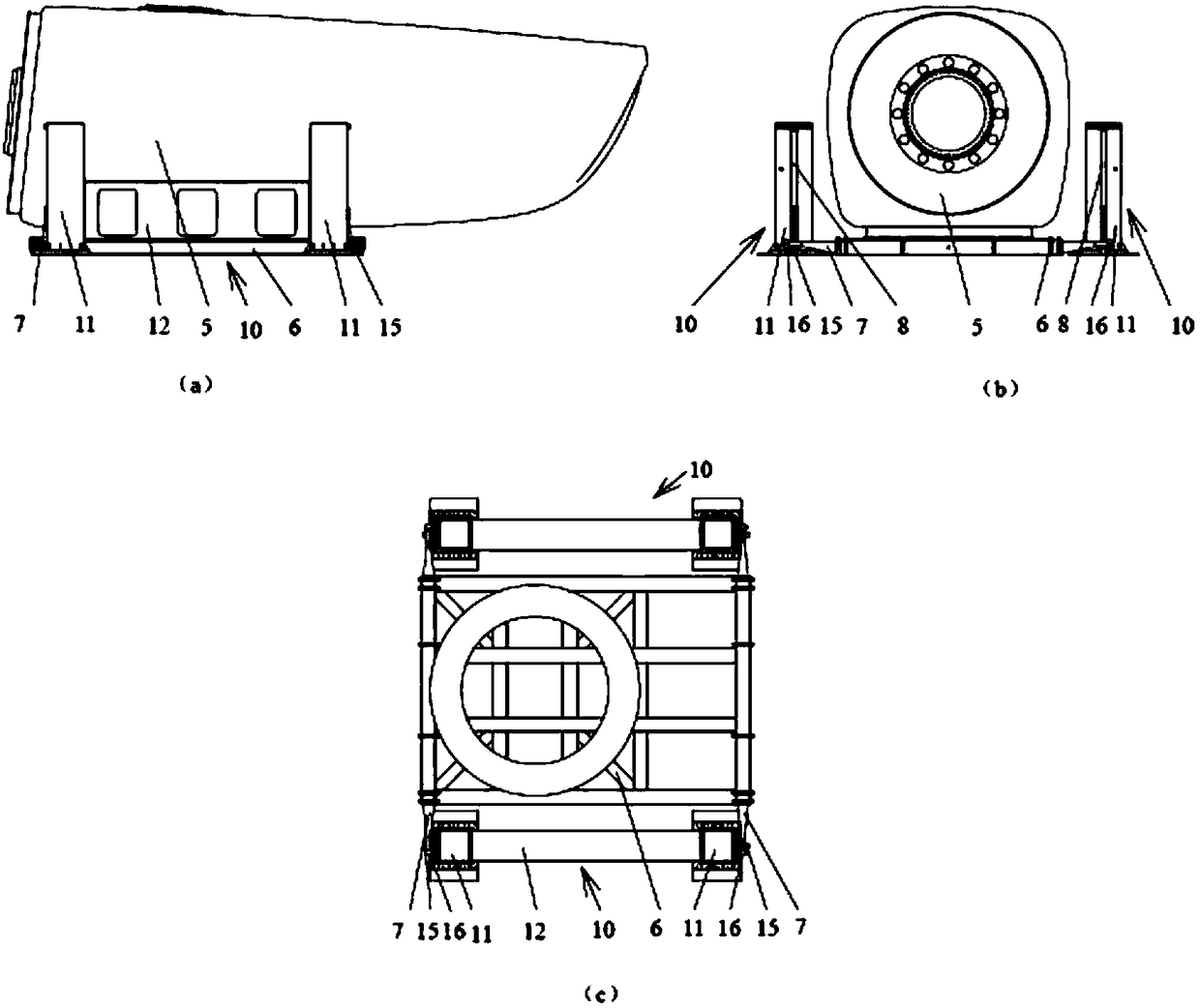

[0029] Such as figure 1 , figure 2 (a), (b), shown in (c), the nacelle self-unloading device of the present invention comprises two jacking devices 10 with the same structure, separated on the left and right sides of the nacelle car and two jacks for connecting both sides. The connector (movable beam) 7 of the lifting device 10, the front and rear ends of the nacelle base 6 are connected with the two connectors 7 respectively.

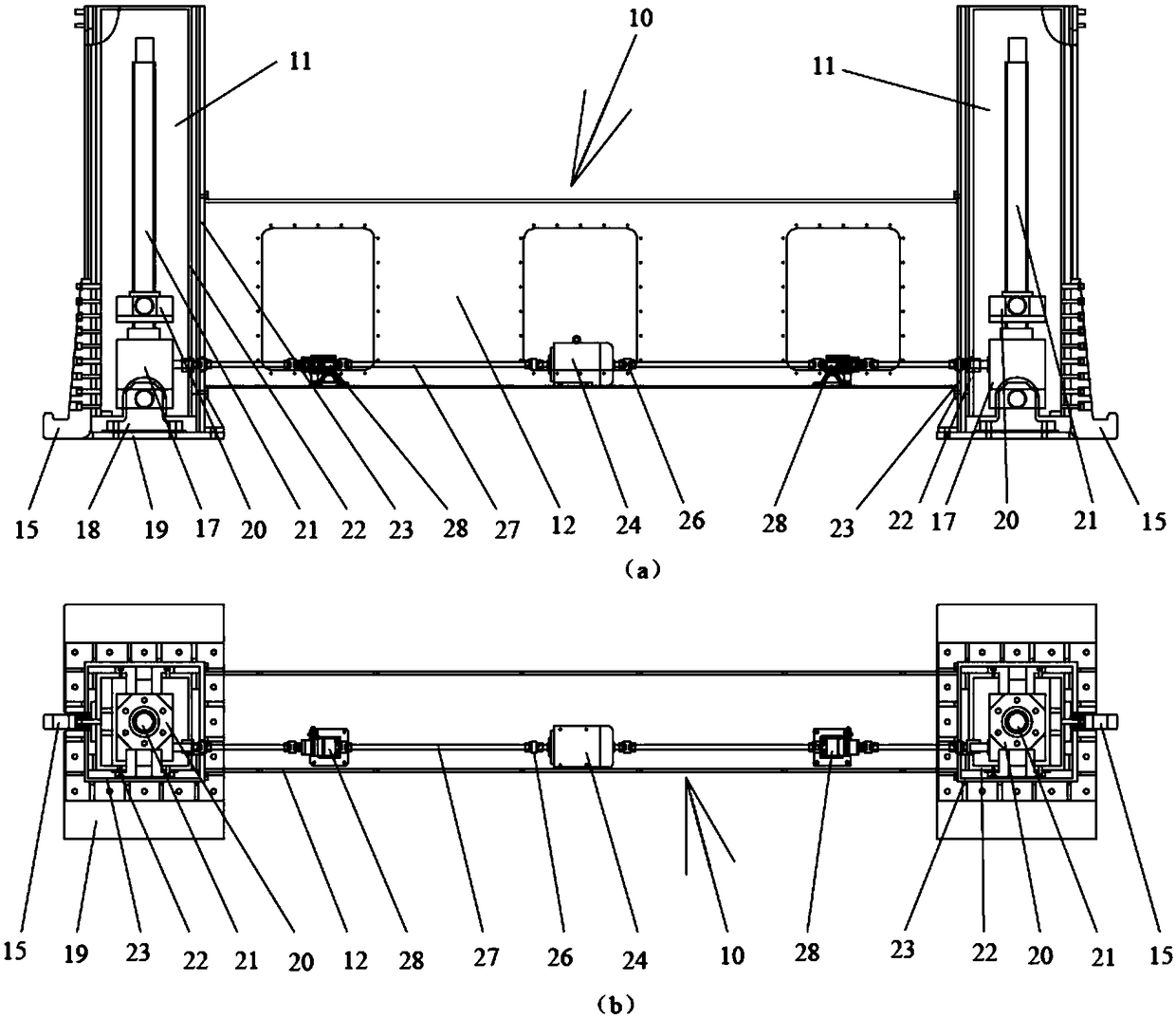

[0030] Such as image 3 (a), (b) and Figure 4 (a), (b), (c), shown in (d), the jacking device 10 is made of two jacking units 11, a connecting beam 12 connecting the two jacking units 11, a drive motor 24, a jaw-type electromagnetic The clutch 28, the connecting shaft 27 and the shaft coupling 26 constitute. The jacking unit 11 is composed of an outer cover 23 , an inner cover 22 , a screw jack 17 , a lift support 18 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com