Hammer drill

A technology of percussion drill and percussion frequency, which is applied in the field of percussion drill, and can solve the problems such as non-self-locking of internal static end teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

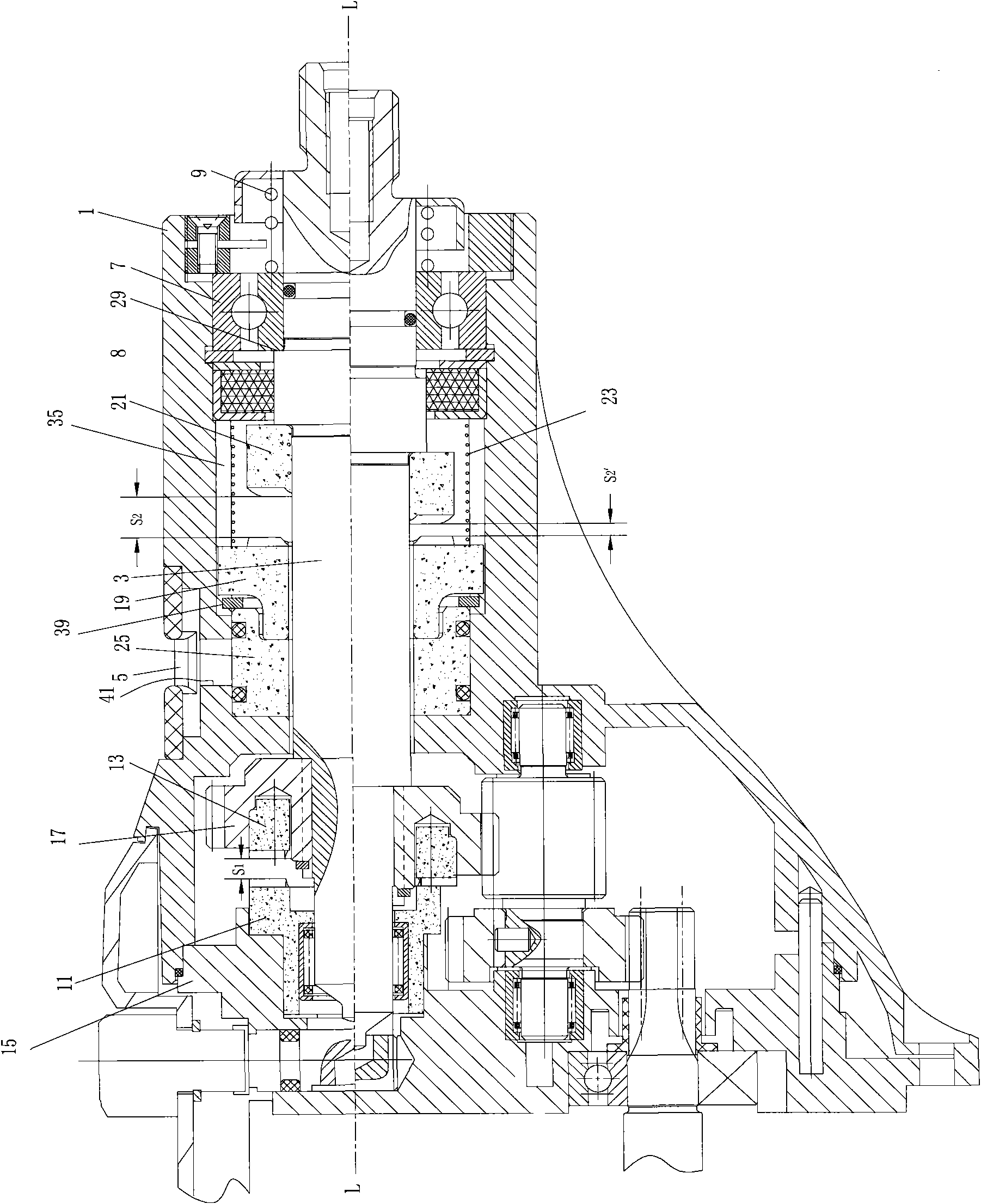

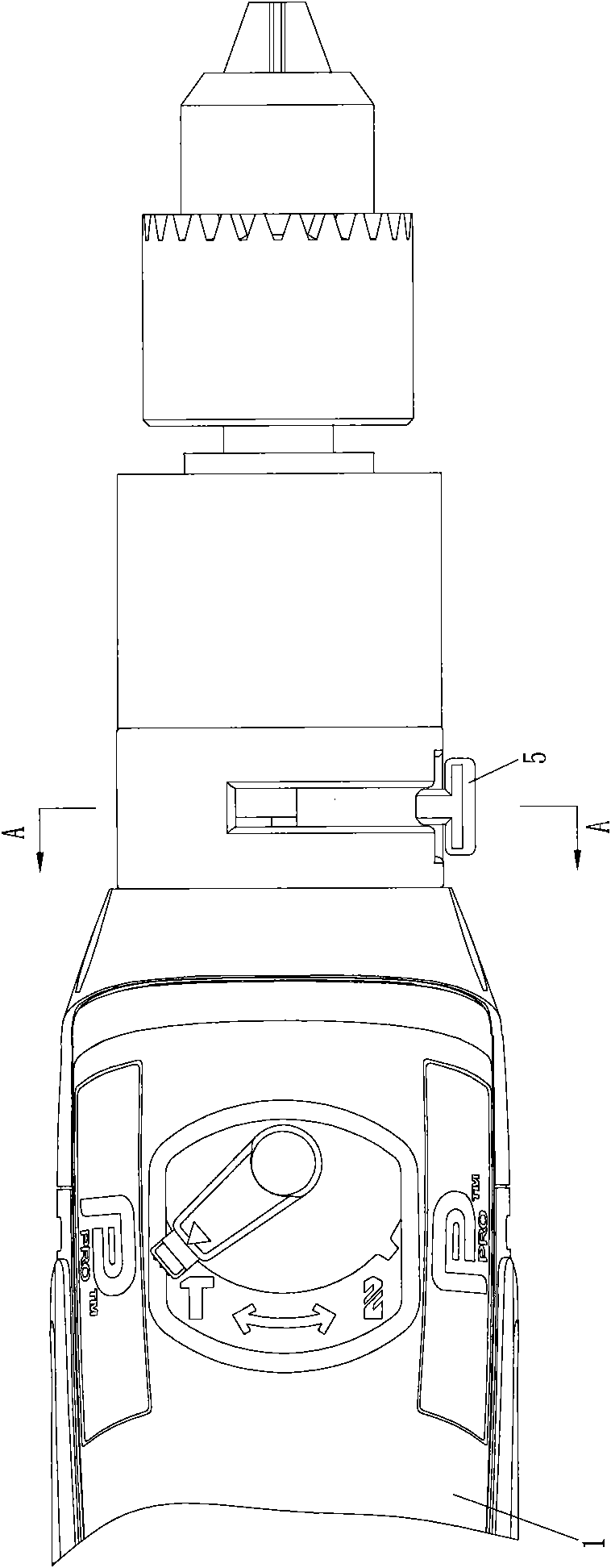

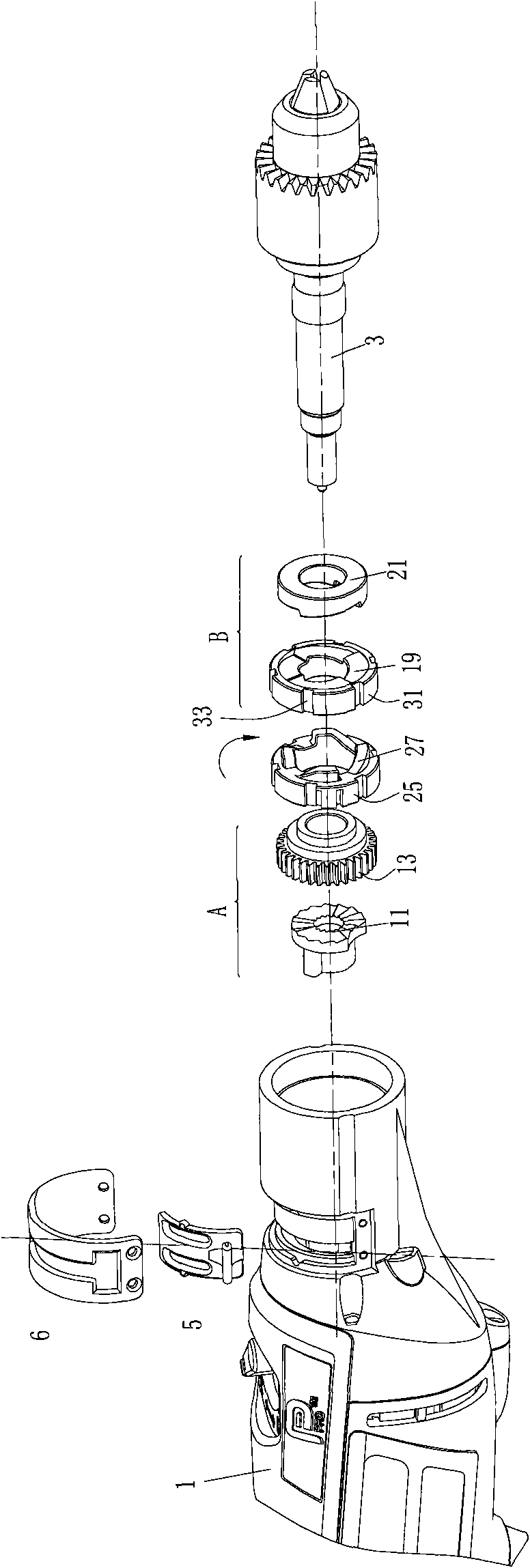

[0059] The first embodiment disclosed in the present invention is:

[0060] Reference Figure 1 to Figure 4 , An impact drill comprising: a housing 1, a driving device (not shown in the figure) accommodated in the housing 1, a rotary output shaft 3 rotatably driven by the driving device, a switch 5 for adjusting the impact frequency, a switch A sleeve 6 is provided thereon, and a spring 9 connected to the bearing 7 of the output shaft 3 is connected to the first set of impact components A and the second set of impact components B on the rotating output shaft 3.

[0061] Wherein, the driving device refers to a motor or a motor or the like.

[0062] The first group of impact components A includes: a first static end tooth 11 fixed relative to the housing 1, and a first movable end tooth 13 fixed to the output shaft 3 and capable of radially moving relative to the housing 1.

[0063] Wherein, the first static end tooth 11 and the end cover 15 fixed to the housing 1 are in an interference...

Embodiment approach

[0085] The second embodiment disclosed in the present invention is:

[0086] Reference Figure 1 to Figure 4 , An impact drill includes: a housing 1', a drive device (not shown in the figure), such as a motor or a motor, and a rotary output shaft 3'that is rotatably driven by the drive device. The switch 5'for adjusting the impact frequency, the spring 9'connected to the bearing 7'of the output shaft 3', the first group of impact components A'and the second group of impact components B arranged on the rotating output shaft 3'in parallel '. The two sets of impact components are in an inner and outer sleeve connection.

[0087] Among them, the first group of impact components A'includes: a first static end tooth 11' fixed relatively to the housing 1', fixed to the output shaft 3'and capable of radial movement relative to the housing 1'. End teeth 13'.

[0088] There is an interference fit between the first static end tooth 11' and the end cap 15' fixed to the housing 1', so the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com