Battery jacking assembly and battery steel shell notch forming mechanism

A battery and component technology, applied in the field of battery steel shell notch forming mechanism, can solve problems such as low precision, and achieve the effects of improving precision, increasing jacking force, and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]In order to further illustrate the technical means and efficacy of the present invention to achieve the object of the present invention, the specific embodiment, characteristics, and efficacy of the battery tape rising assembly and the battery steel shell in accordance with the present invention, detailed description Rear.

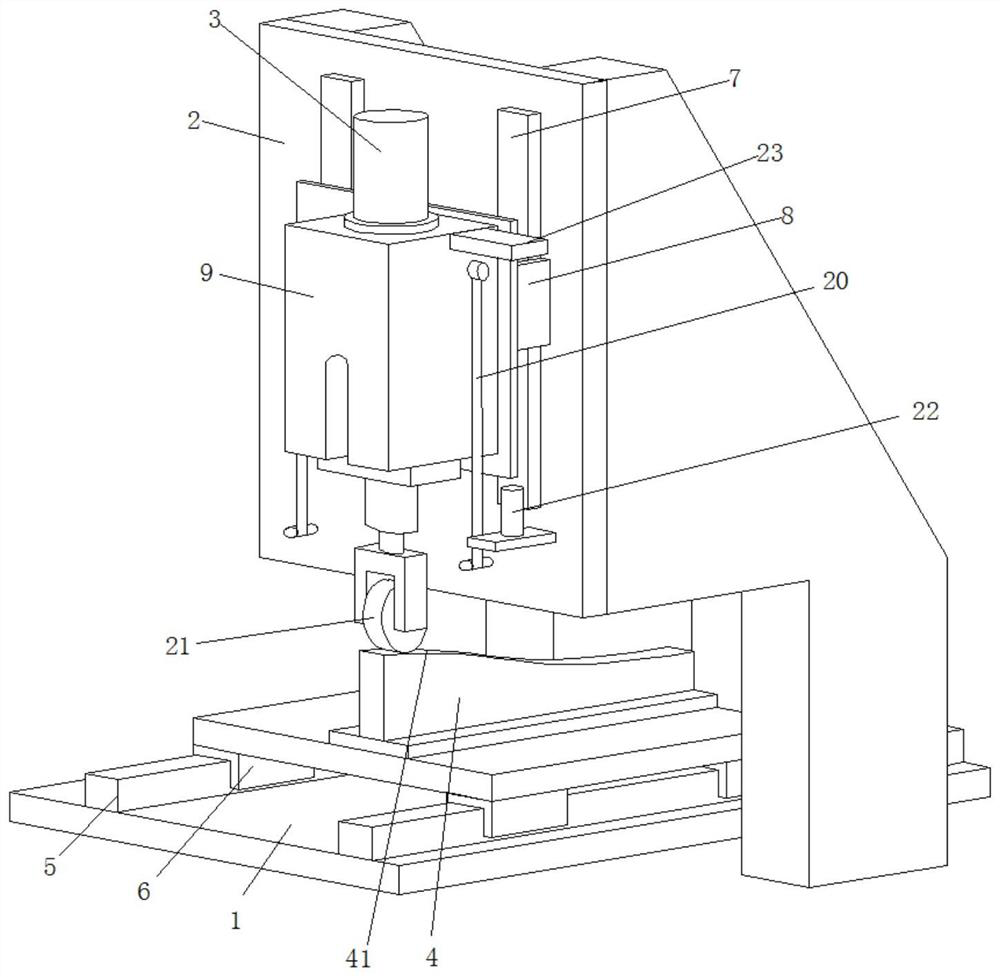

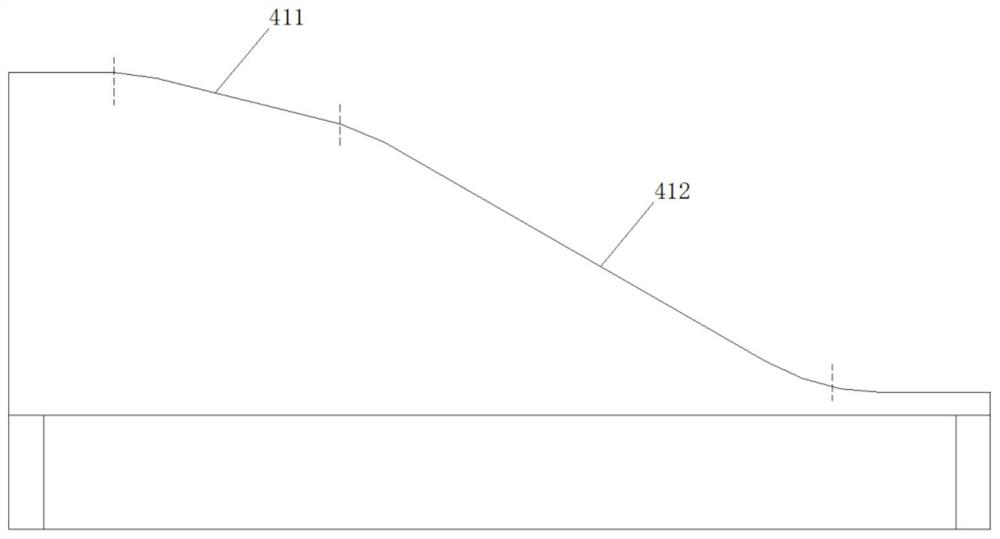

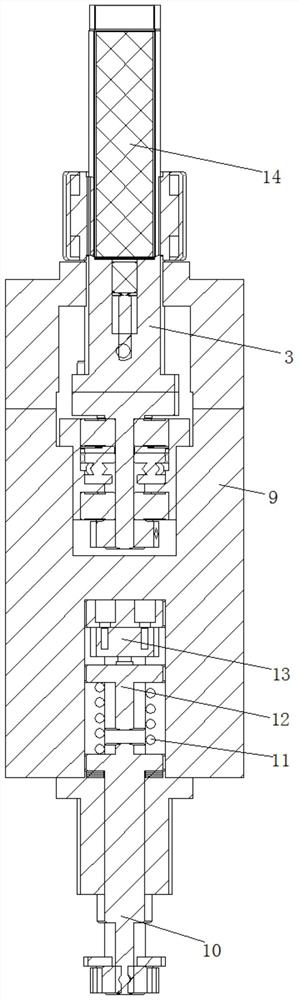

[0059]The present invention discloses a battery top rising assembly, including: a stent, a side panel 2 provided in a bottom plate 1 and a tape rising direction; a chassis assembly for carrying a battery 14, and the underwrapping component is slid on the side panel 2 And the direction of the sliding direction is the top rising direction; the guide block 4, the guide block 4 slides on the bottom plate 1, and the guiding block 4 is used opposite the bottom trace assembly for carrying the base holder assembly, the first drive, and the guide block. 4 is connected to provide a sliding power for the guide block 4; wherein the side surface of the guide block 4 oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com