Lower die ejector of forging die

A technology for ejectors and molds, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. Problems such as the difficulty in normal production of the wheel hub, to achieve the effect of increasing the ejection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

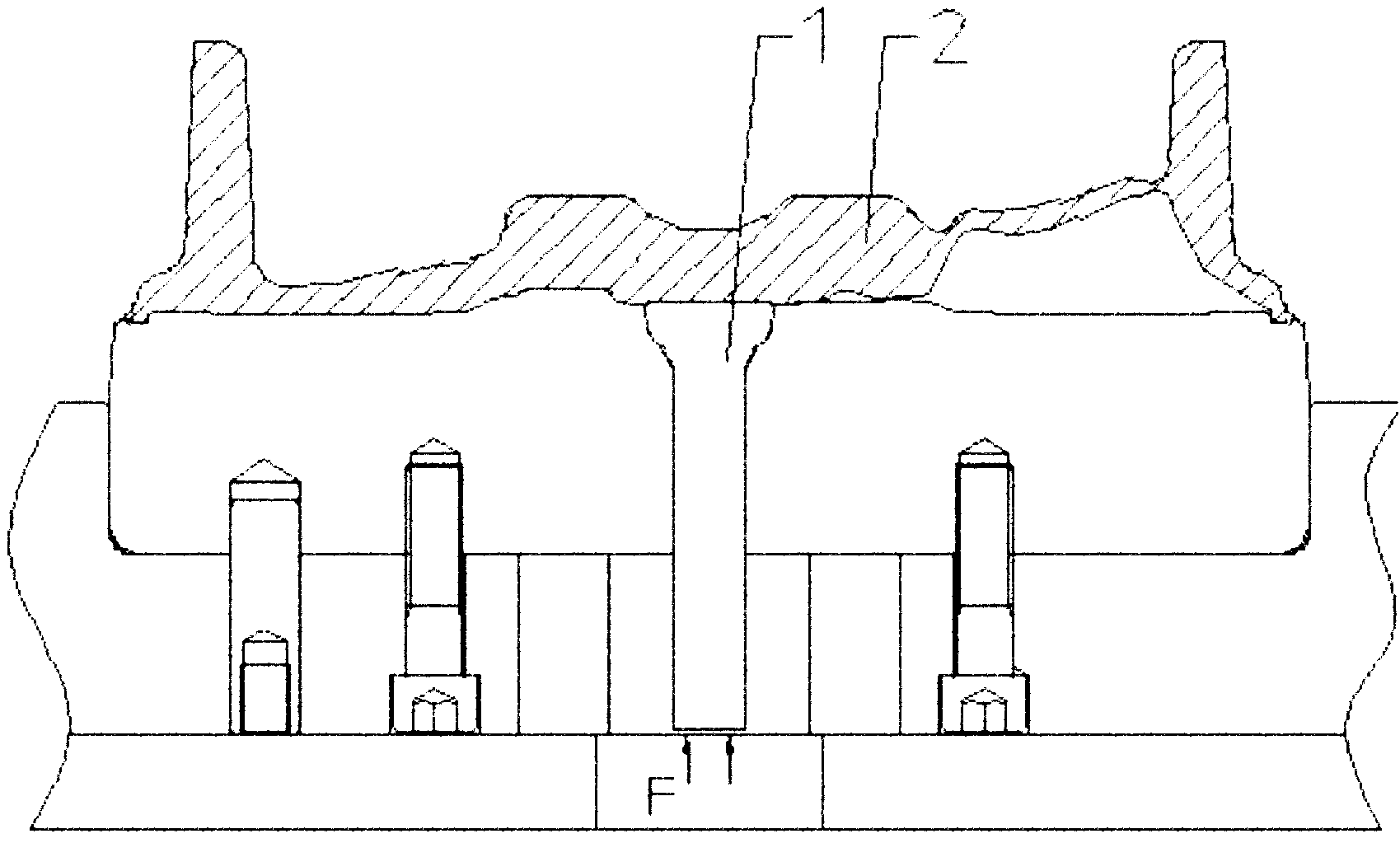

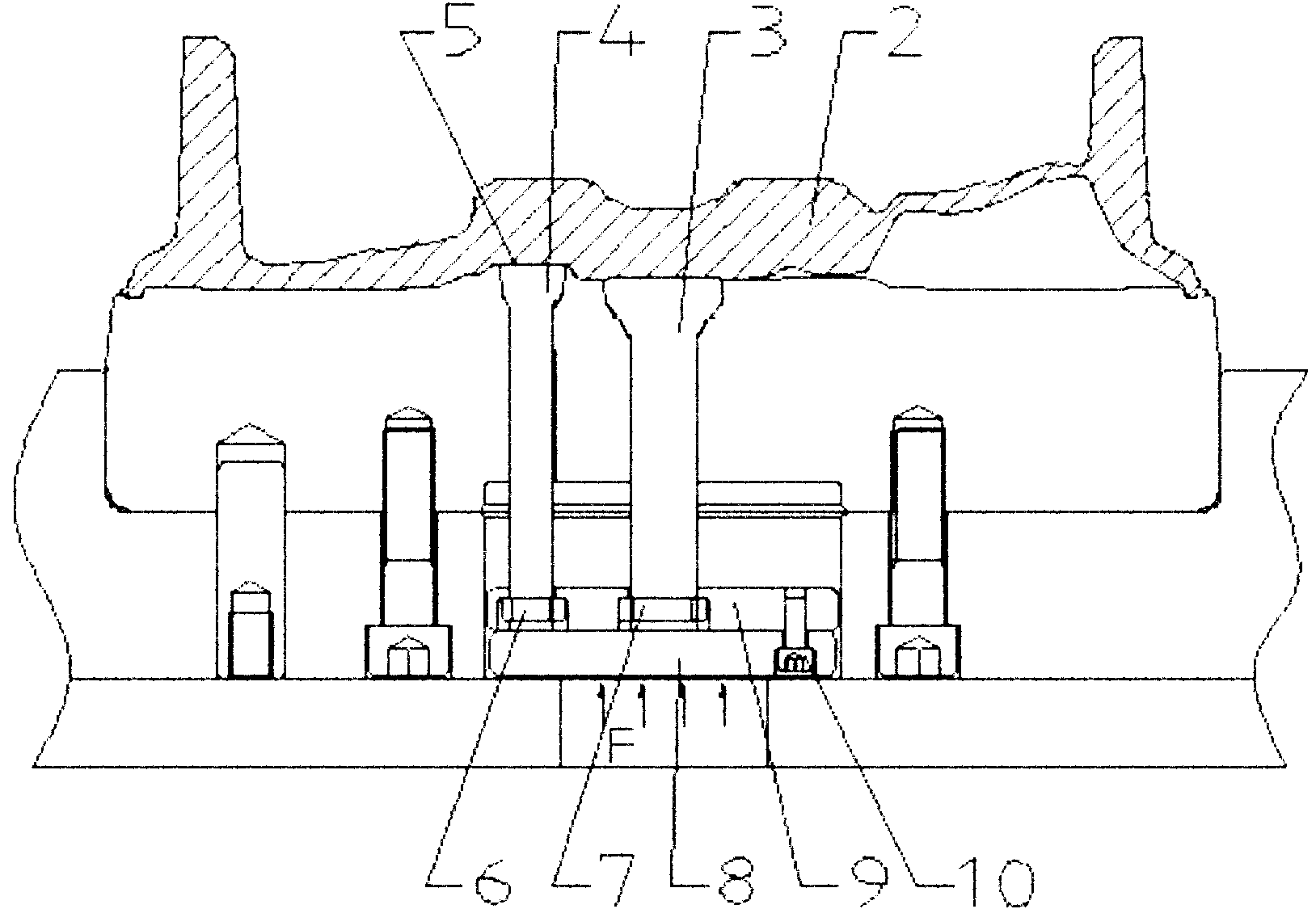

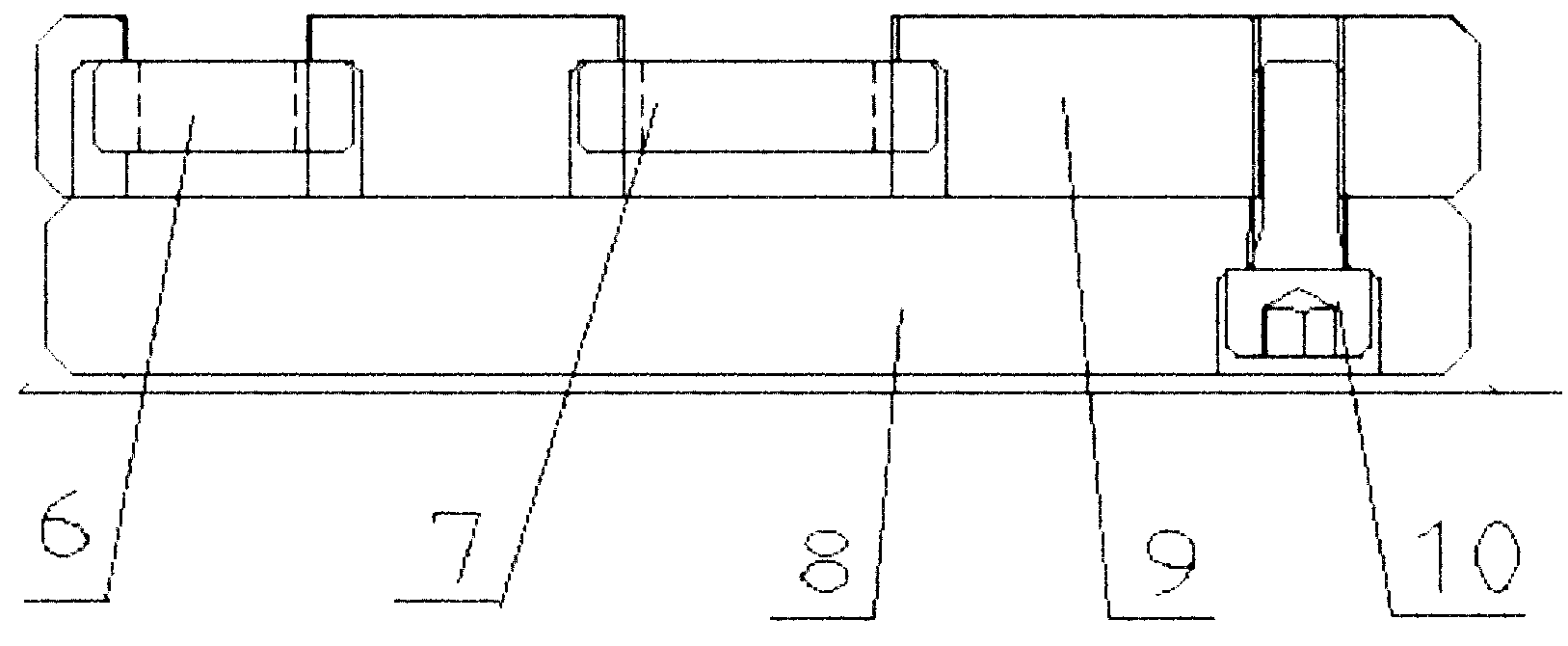

[0010] like figure 2 , image 3 As shown, the existing lower die ejector rod 1 is replaced with the central lower die ejector rod 3, and the auxiliary lower die ejector rod 4 is added at the plane of the bolt hole boss on the front of the blank. The quantity of the auxiliary lower die ejector rods 4 to be increased is based on the quantity of the bolt hole bosses 5 of the blank. The ejector rods 3 of the central lower die and the ejector rods 4 of each auxiliary lower die are connected with the upper plate 9 of the ejector pin, the lower plate 8 of the ejector pin, the central clamping plate 7 and the auxiliary clamping plate 6 . The upper plate 9 of the push rod and the lower plate 8 of the push rod are connected with bolts 10 . The entire system is combined as a lower die ejector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com