A lower ejector device for heavy-duty forging machine

A technology of ejecting device and forging machine, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problem of low overall structural rigidity, small ejection force, and inability to achieve stepless ejection force Program control and other problems, to achieve the effect of stable and reliable ejection process, stable and reliable movement, and large ejection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with the accompanying drawings and specific embodiments.

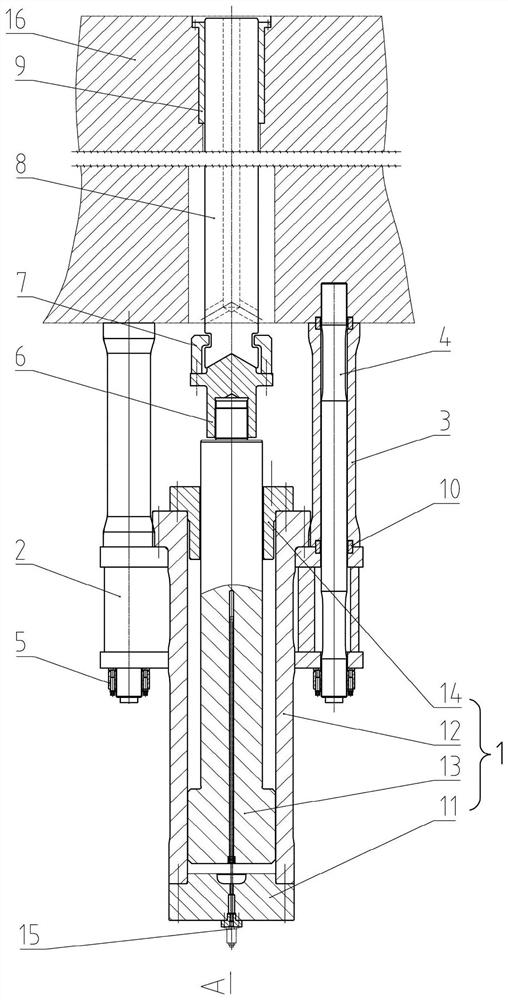

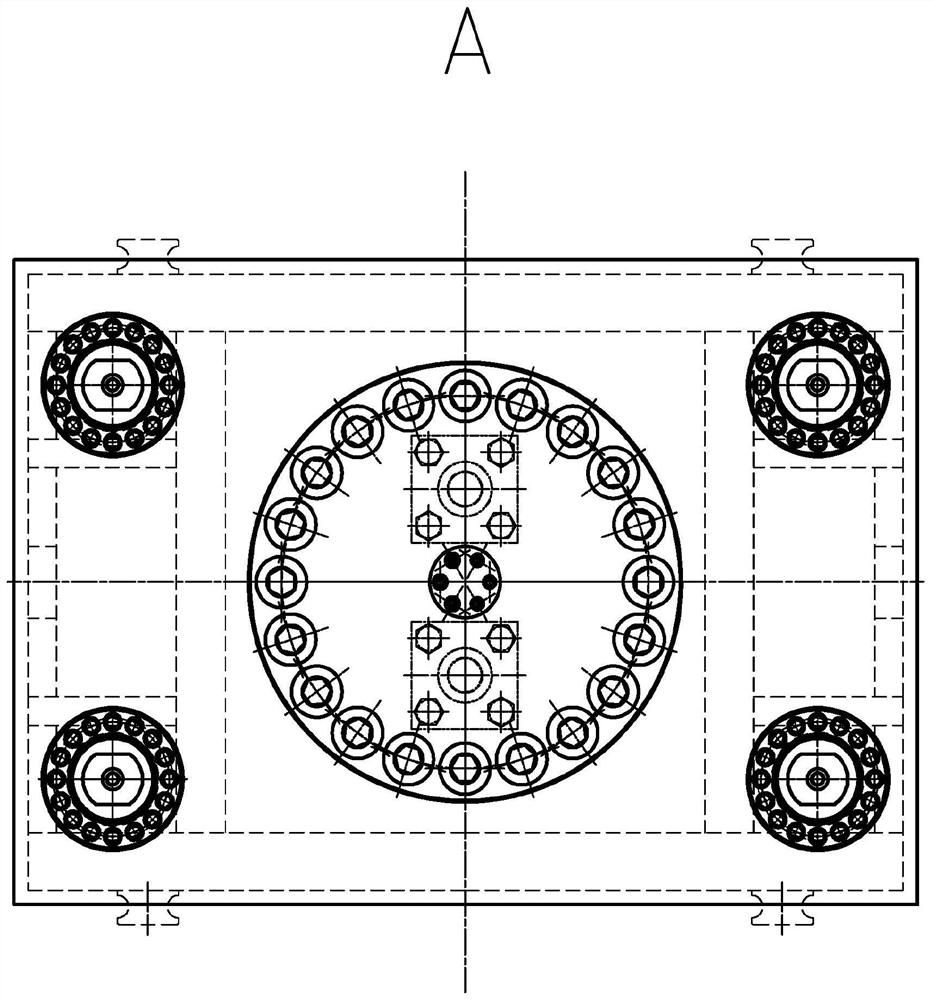

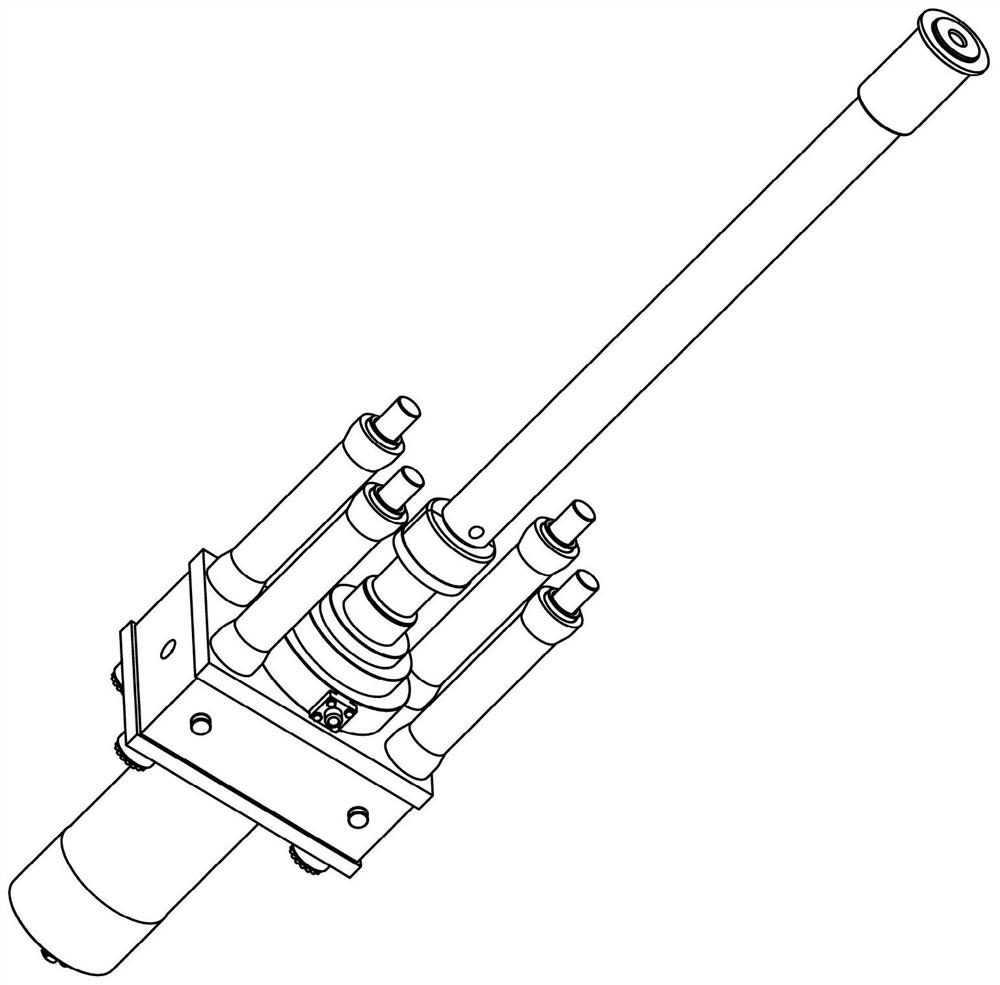

[0022]Lower ejector device for heavy-duty forging machine, including forging machine base 16, hydraulic cylinder 1, support mechanism and ejection mechanism, hydraulic cylinder 1 including cylinder bottom 11, cylinder block 12, piston rod 13, and cylinder head 14; hydraulic cylinder 13 top section of the piston rod 13 is provided with threads, the bottom 11 center part of the cylinder is provided with a through hole of the cylinder bottom 11, the piston rod 13 bottom processing blind hole; the ejection mechanism includes pressure pad 6, hook plate 7, ejector rod 8 and displacement sensor 15, pressure pad 6 is a cylinder with a cone surface, The lower part of the cylindrical cone top surface is provided with a ring of bosses along the circumference of the cylinder, the bottom surface of the cylinder is flat, and the center of the bottom surface is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com