Reciprocating pulling type super-tonnage steel box girder continuous traction device and using method thereof

A traction device and super-large-tonnage technology, which is applied in the field of super-large-tonnage steel box girder installation and construction, can solve the problems of large engineering volume and low construction efficiency, achieve construction safety, convenient operation, and reduce the use of large-scale equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

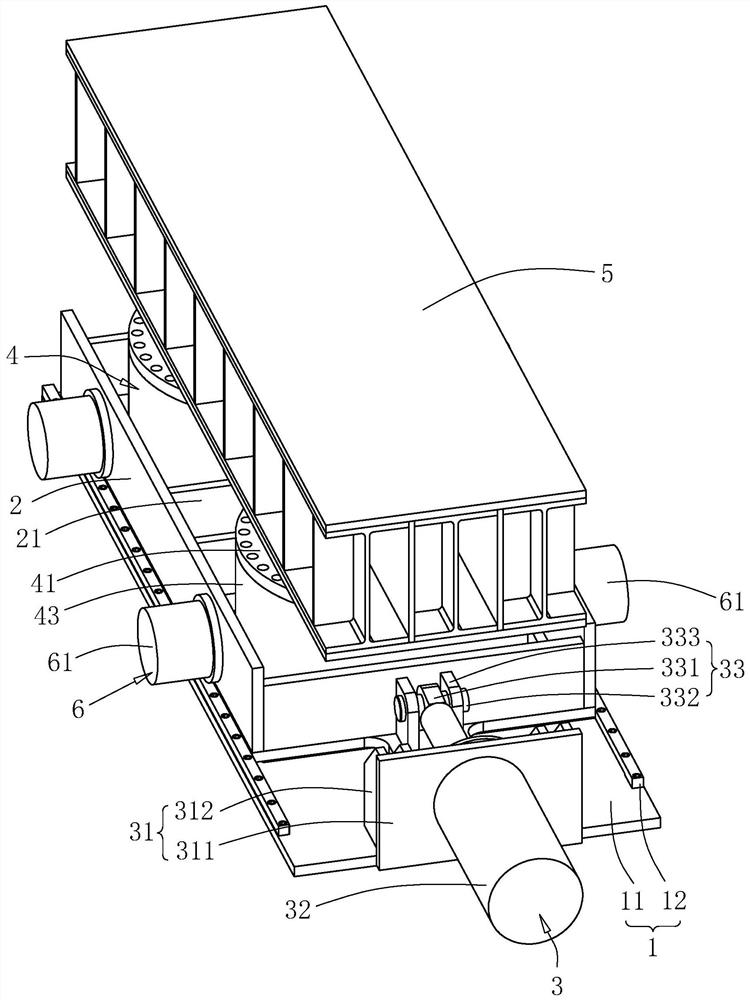

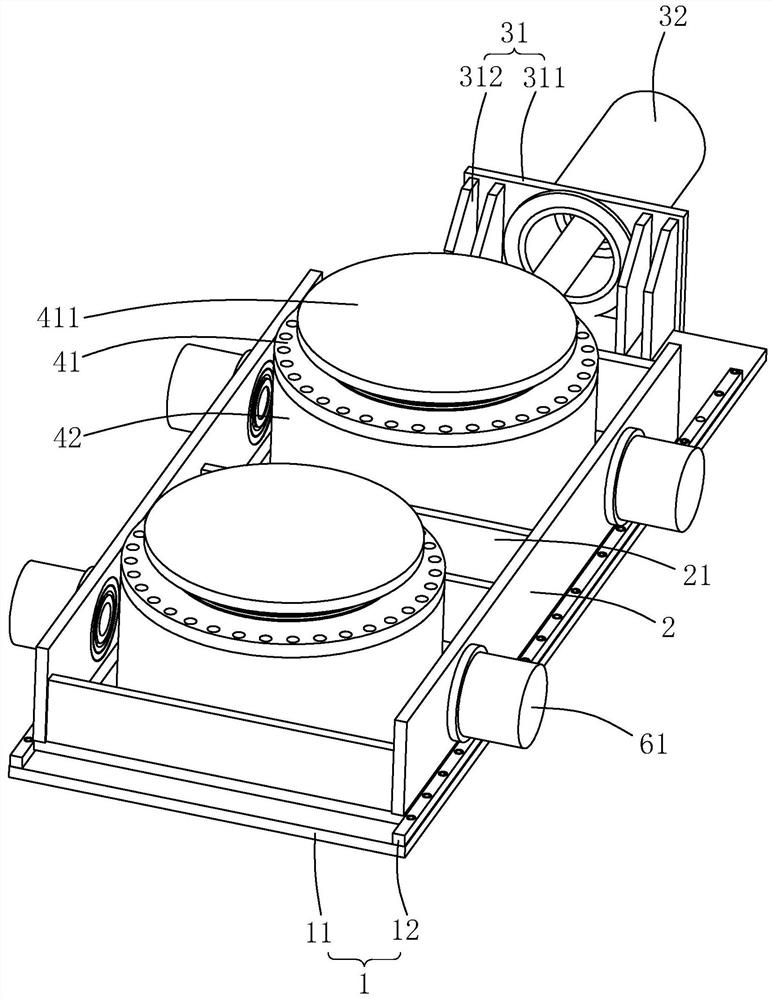

[0043] The following is attached Figure 1-2 The application is described in further detail.

[0044] The embodiment of the present application discloses a reciprocating pulling type continuous pulling device for super large tonnage steel box girder. refer to figure 1 , The reciprocating pull type super large tonnage steel box girder continuous traction device includes an anchor base 1, a main frame 2, a jacking mechanism 4, a pad beam 5, a deviation correction mechanism 6 and a traction mechanism 3.

[0045] refer to figure 1 The anchor base 1 includes an anchor base plate 11 and a limit strip 12. Two limit strips 12 are arranged at intervals along the length direction of the anchor base plate 11 on the anchor base plate 11. The two limit strips 12 are fixed on the anchor base plate 11 along the length direction by bolts. On both sides of the two limiting strips 12, the top wall of the anchoring bottom plate 11 has been mirror-polished and coated with lubricating oil.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com