Method for jacking large-sized prefabricated parts

A prefabricated component and jacking technology, applied in the direction of lifting devices, etc., can solve the problems of reduced site utilization, high construction cost of prefabricated yard, high bearing capacity, etc., and achieve the reduction of construction cost, reduction of construction cost and increase of force-bearing area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

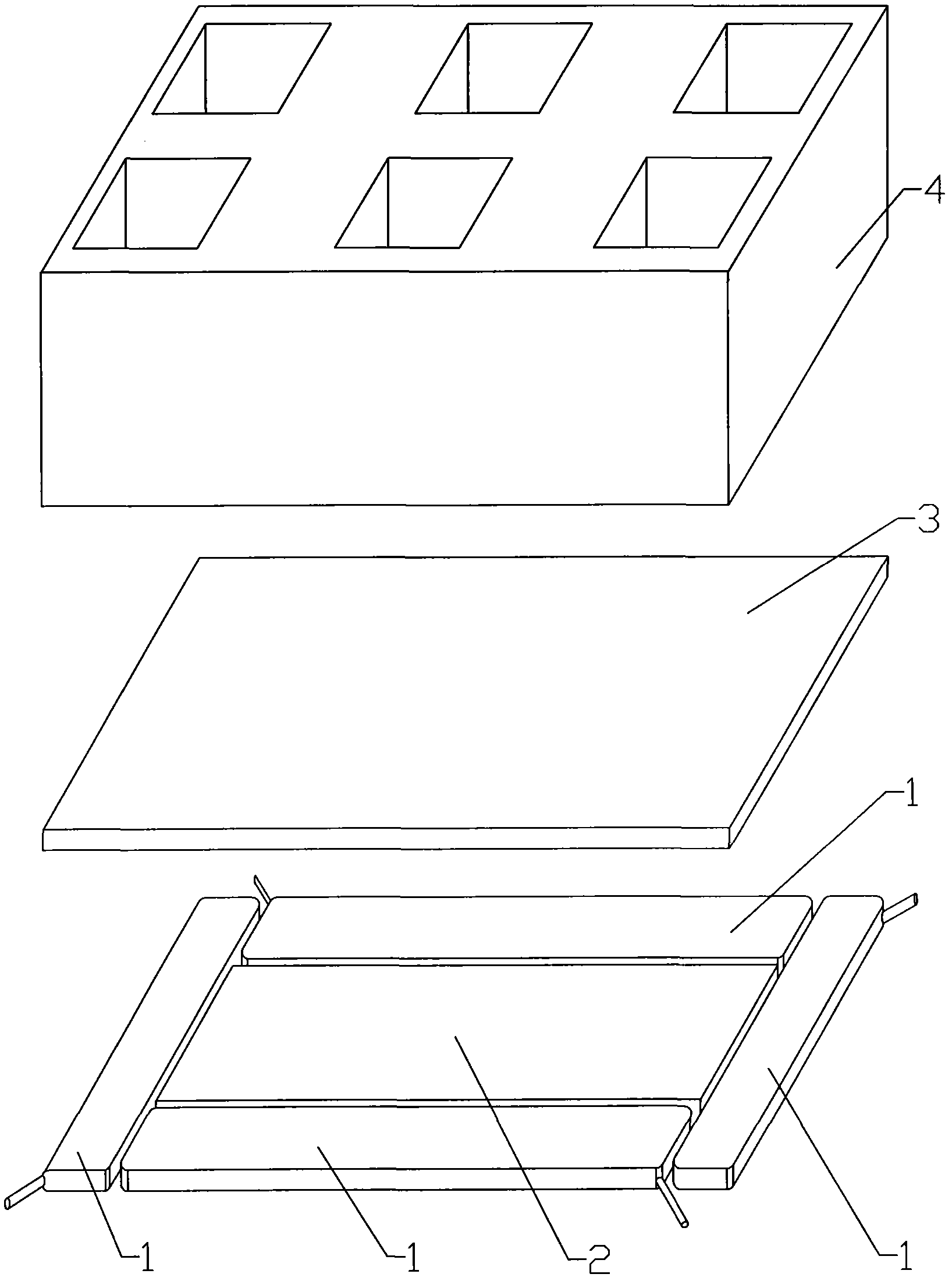

[0049] Embodiment 1: as figure 1 As shown, a jacking method for a large prefabricated component, first place flat airbags 1 on the prefabricated pedestal according to the size of the base of the prefabricated component 4, connect the four airbags 1 in parallel or in series with pipelines, and fill the airbag 1 with water , so that the upper plane of the airbag 1 forms a construction horizontal reference plane, the middle of the airbag 1 is filled with filler 2, the filler is sand, so that the sand and the upper plane of the airbag 1 are on the same plane, and then the bottom plate is laid on this plane 3. Install the formwork of the prefabricated component 4 on the periphery of the airbag 1 , that is, the prefabricated component 4 . When the prefabricated component 4 reaches the maintenance period, the airbag 1 is filled with water or air, and the airbag 1 lifts the prefabricated component 4 to complete the jacking of the large prefabricated component 4 .

[0050] To lift the...

Embodiment 2

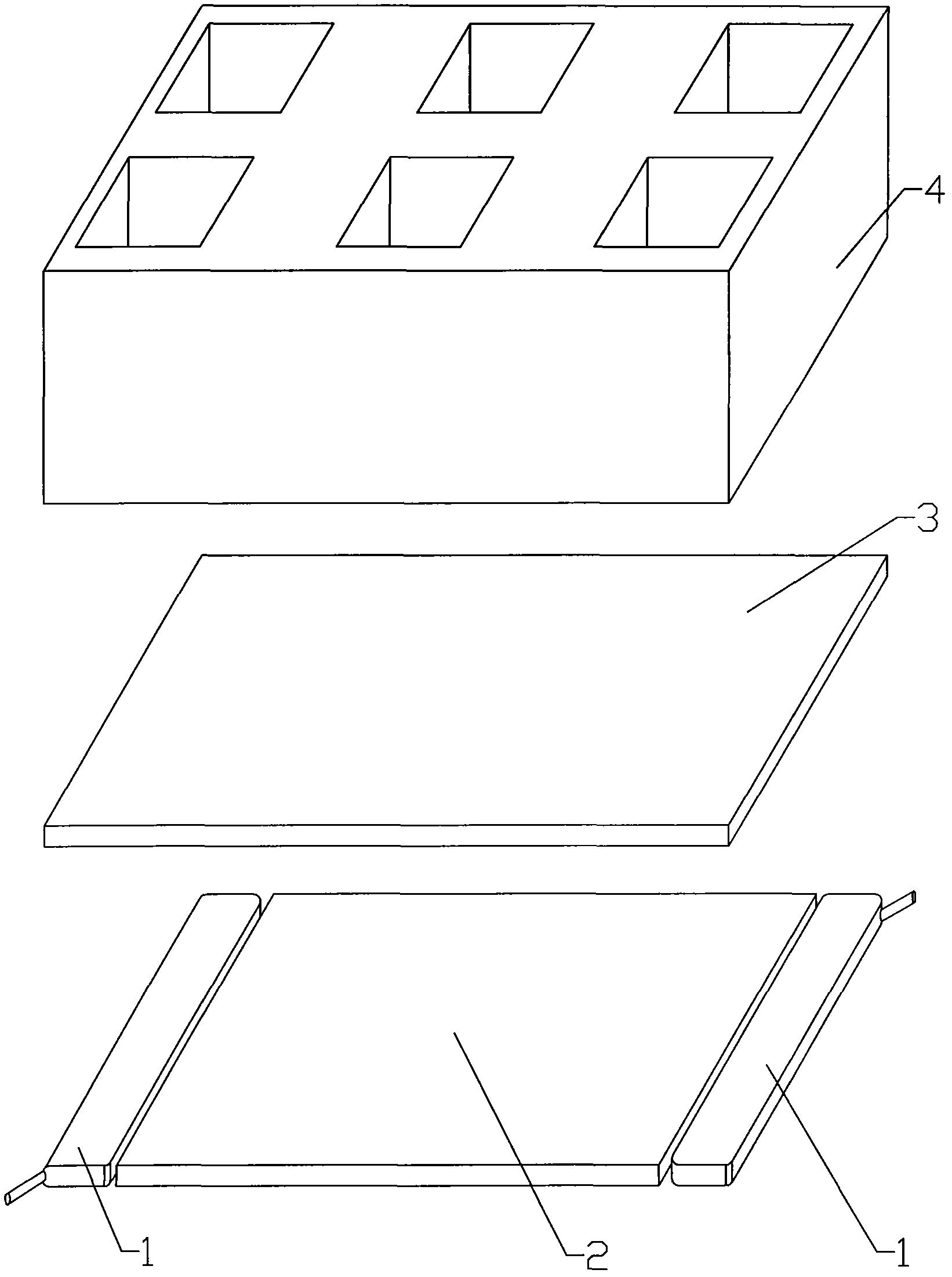

[0051] Embodiment 2, as attached figure 2 As shown, a jacking method for a large prefabricated component, first place two flat airbags 1 on the prefabricated pedestal according to the size of the base of the prefabricated component 4 at both ends of the prefabricated component 4, and the two airbags 1 are arranged in parallel, namely The axis of the airbag 1 is perpendicular to the delivery direction of the prefabricated component 4; water is injected into the airbag 1 so that the upper plane of the airbag 1 forms the same horizontal reference plane, and the space between the airbags 1 is filled with fillers 2, which are wooden boards , adjust the water injection volume of the airbag 1, so that the filled plank is on the same plane as the upper plane of the airbag 1, and then lay the bottom plate 3 on this plane, and install the formwork around the airbag 1, so that the component 4 can be prefabricated. When the component 4 reaches the maintenance period, the air bag 1 is fil...

Embodiment 3

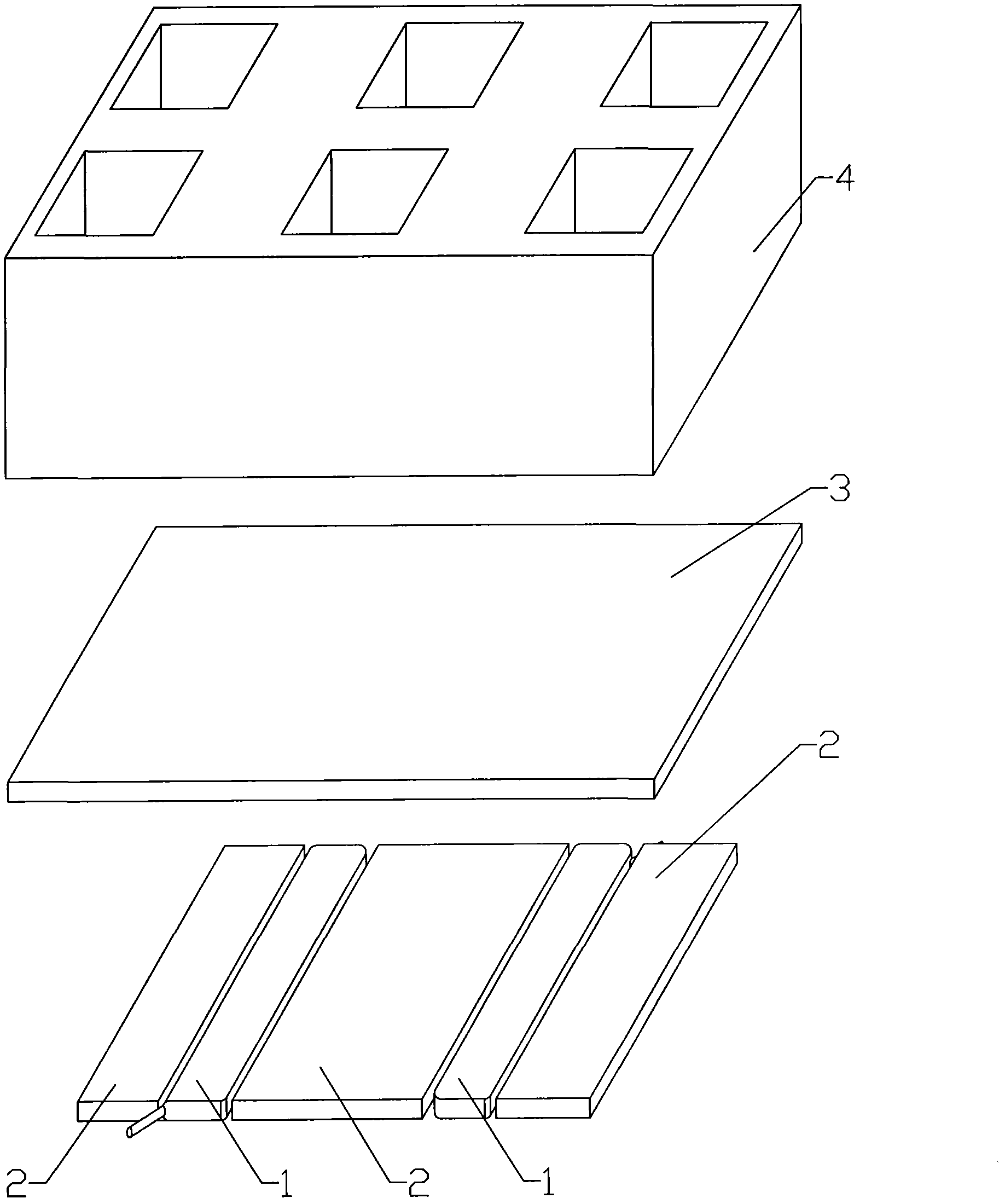

[0053] Embodiment 3, as attached image 3As shown, a jacking method for a large prefabricated component, first place two flat airbags 1 and two flat airbags on the prefabricated platform according to the size of the base of the prefabricated component 4, and according to the force point or length of the base of the prefabricated component 4. 1 Arranged in parallel, that is, the axis of the airbag 1 is perpendicular to the delivery direction of the prefabricated components; the two airbags 1 are connected in parallel or in series with pipelines, and water is injected into the airbag 1 so that the upper plane of the airbag 1 forms a reference level, and the upper plane of the airbag 1 The surroundings are filled with filler 2 sand and soil, so that the filler and the upper plane of the airbag 1 are on the same plane, and then the bottom plate 3 is laid on this plane, and the template is installed on the periphery of the airbag 1, so that the component 4 can be prefabricated. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com