Secondary ejecting mechanism

A technology of secondary ejection and plate ejection, which is applied in the field of ejection mechanism, can solve problems such as small ejection force, product breakage and strain, complex mechanism, etc., and achieve large ejection force, good reliability and durability, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

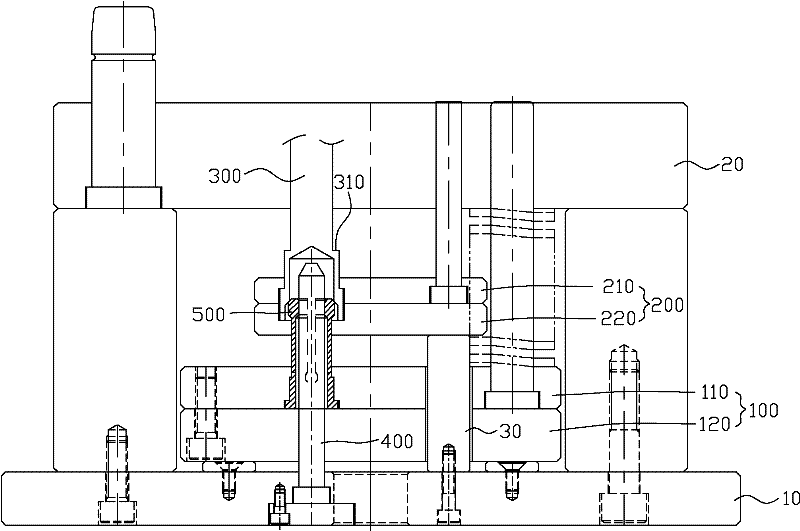

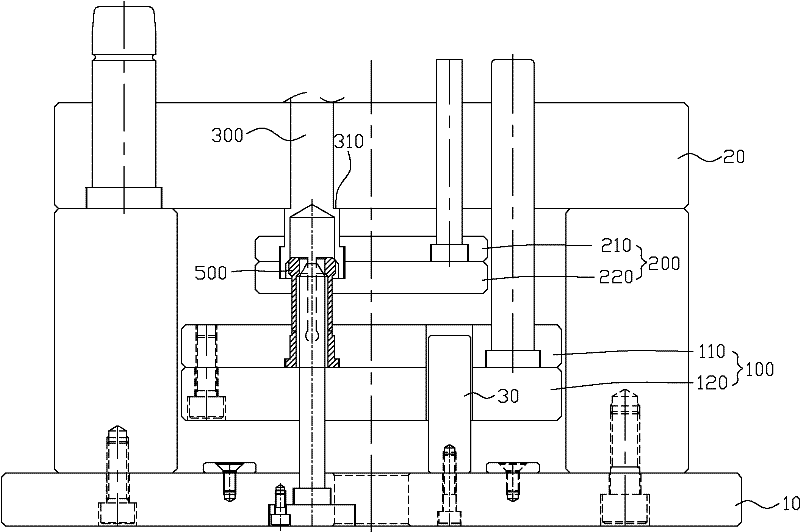

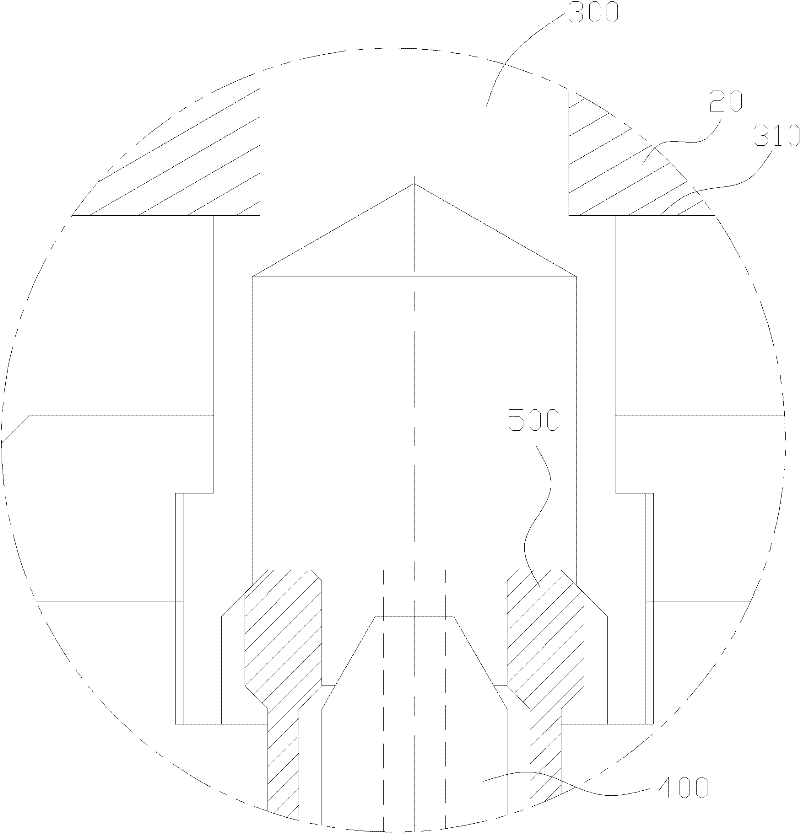

[0016] see figure 1 As shown, it shows a schematic diagram of the secondary ejection mechanism of the present invention.

[0017] The secondary ejection mechanism of the present invention is applied in a mold, and the mold includes: a lower fixing plate 10, a male template 20, a female template (not shown), and a support rod 30, and the secondary ejection mechanism includes:

[0018] A first ejector plate 100, which is located on the lower fixing plate 10 of the above-mentioned mould, the first ejector plate 100 is provided with a first upper ejector plate 110 and a first lower ejector plate 120;

[0019] A second ejector plate 200, which is located on the support rod 30 of the above-mentioned mold, the second ejector plate 200 is provided with a second upper ejector plate 210 and a second lower ejector plate;

[0020] A limiting rod 300, one end of which is arranged in the above-mentioned second ejector plate 200, and the other end is arranged in the mother template (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com